Metro Network in the Lion City Singapore

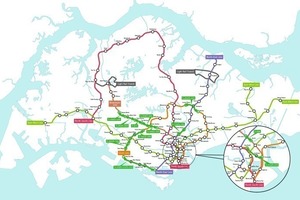

The Asian city state of Singapore has experienced an enormous economic growth over the past few years. The requirements placed on the transportation infrastructure of this metropolis (5 mio. inhabitants) have risen to the same extent. Since the island state has only limited land available, developing a highly efficient metro network is the quickest and most space-saving way of linking the essential points of the island with one another. The Land Transport Authority (LTA) contractor, which is responsible to the Transportation Ministry, has set its ambitious target of doubling the existing Mass Rapid Transit (MRT) network. The idea is to grow to a total of 278 route km by 2020.

In 2003, the 20 km long North-East Line with its 16 stations was placed into service to link the center of Singapore with the north-eastern section. 2 Herrenknecht EPB Shields (6.55 m diameter) were involved in developing the rail network; they excavated 2 double-tubed metro tunnels of a total 3,200 m length. In view of the changing ground conditions to be expected, the cutting wheels were adjusted to the geology and additionally equipped with hard rock cutting tools. This resulted in tunnelling performances of up to 140 m per week with both machines experiencing the final breakthrough in November/December 1999.

Additional lines such as the Circle Line (CCL) and Downtown Line (DTL) are currently being built to ensure new rapid connections within Singapore. The 33.3 km Circle Line with its 29 stops should be finished and in fully automatic operation in 2011. Its Botanic Garden and Serangoon stops provide a direct connection to the North-South and North-East Metro Line. In particular, the many commuters will benefit from the new line skirting in future the crowded stations in the south. 9 Herrenknecht EPB Shields (7x 6.60 m diameter; 2x 6.58 m diameter) made their way through the underground composed in part of the “Jurong” formation with its fresh to weathered sandstone.

The EPB Shields’ working principle revealed its true worth in Singapore’s ground of soft geological formations and low water permeability. The soil excavated by the cutting wheel is used to support the tunnel face. Foam injected in front of the cutting wheel makes the excavated soil into a paste, guaranteeing the exact control of the support pressure as well as the efficient removal of the excavated soil. The decision was made in favor of the Herrenknecht Mixshield technology (2x 6.64 m diameter) for the 2.9 km section between the One-North and Farrer Road stations. Using the machines more than 23,000 m of tunnelling were achieved for the Circle Line.

Construction of the new Downtown Line Stage 3 (DTL3) which is about to start is split into 3 phases and will be completed by 2016. 500,000 passengers a day will eventually be using the new line. It makes direct connection possible from the north-western and eastern part of the island to the Central Business District and Marina Bay. The benefits are obvious in that the traveling time will be cut by a third from the Bukit Panjang Station to the city center. In addition, commuters from the Bedok Reservoir and Tampines can change from bus to the more rapid metro link.

For the second phase of the new Downtown Line Stage 2 (DTL2), faith again is being placed in Herrenknecht tunnel boring machines. The machines are designed and constructed in Germany where manufacturing is also undertaken of the main components, such as cutting wheel drive and process technology including control cabin and hydraulic station. After being shipped they are then assembled in the Herrenknecht workshops in Guangzhou/China.

The intention is for 10 machines (6x EPB Shield; 4x Mixshield; 6.66 m diameter each) to work their way through the geology. The first 2 Mixshield TBM for the lot C916 have successfully passed workshop acceptance in 2010 with a planned start of jobsite assembly in May 2011. In December 2010 and January 2011 the first 2 EPB Shields for the lot C919 were also accepted at the workshop with a planned start of jobsite assembly also in May 2011. Construction and assembly of the remaining 6 machines (lots C917 and C918) is currently under way.

To avoid any clogging in the heterogeneous ground and at the same time break the hard Bukit Timah granite, the designers have opted for a hard rock cutting wheel with sufficient opening ratio and edging done with a large number of disc cutters, especially in the gauge area. The cutting tools are designed with new bigger shaft dimensions, pressure compensation units to overcome high pressure up to 4 bar, additional wear protection and special cutter rings. The machines’ cutterheads are equipped with a driving power ranging from 1,200 kW to 1,750 kW. To prevent any impediment to the tunnelling works of the 2 Mixshields, the customer also insisted on delivery of 2 effective separation plants (overall capacity: up to 2,400 m3 an hour) for separating the excavated ground from the bentonite suspension.

The design of the segment rings defines a ring division of 5+1 and a ring length of 1.40 m. The inner diameter will be 5.80 m at an outer diameter of 6.35 m.

Equipping will in all probability be such by 2015 so as to see completion of the second phase of the project with its 16.6 route km and 12 stations.