Mechanized Tunnelling for two new Metro Lines in Rome

In Rome, 2 new lines for the metro are currently under construction. A total of approx. 33 km of tunnel are to be constructed by 7 Earth Pressure Balance Shields for the Lines B1 and C. The following article gives an overview over the project.

Rome, the Eternal City, is famous, amongst other things, for its wealth of archaeological sites revealing the city’s historical roots. No matter what means of transport you use when visiting the city, you will have the sensation of jumping between the centuries in the face of so much archaeology, art and culture.

Today, Italy’s capital has about 2,720,000 inhabitants and about 2,660,000 registered cars, i.e., about 98 cars per 100 inhabitants compared to approx. 40 cars/100 in London or 42 cars/100 in Paris. These figures illustrate why Rome is considered to be among the cities with the highest density of car traffic in Europe.

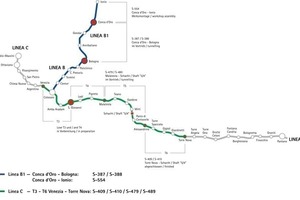

Compared to the traffic above ground, the subway has a good reputation, being punctual and reliable. At present, the Metropolitana di Roma has 2 lines, the Linea A and Linea B (Fig. 1). The first one is 19 km long and it extends from north-west to south-east; it is composed of 27 stations and it is able to transport 450,000 people in 537 daily trips. The second one, Line B, extends from the north-east to the south with a length of 19 km and 22 stations. Approx. 300,000 passengers are transported daily on 377 “rides”. Major efforts are being made to improve the traffic situation in Rome by expanding the existing subway network by constructing 2 new subway lines, Line C and Line B1, the latter of which is a branch of the already existing Line B (Fig. 1). The first section of metro Line C will connect Parco di Centocelle with Pantano and will have 15 stations. The carrying capacity will be 24,000 passengers per hour for each line.

In total, Line C will be 25.5 km long including 17.6 km underground and 7.9 km above ground with a total of 30 stations. The lots T2, T3, T4, T5, T6A and T7 are currently under construction. Line B1 will be 4.5 km long with 4 new underground stations.

While the trains of the Line B1 will be driven and controlled conventionally, the trains of the metro Line C will be controlled remotely by a system called “Driverless”. The system is based on an innovative program called ATC (Automatic Train Control), located in the Central Operation Center. From here it will be possible to check every situation through monitors and computers connected to a network of video cameras.

The Driverless, therefore, offers maximum safety and punctuality, a train every 75 seconds, and a trip from one railhead to the other will take only 45 minutes, including stops at stations. Another advantage is savings of a minimum of 14 % and a maximum of 20 % on operating

costs and maintenance.

Another feature of the Driverless system which will offer maximum safety and comfort on metro Line C will be the automatic platform doors, which will only open when a train arrives and are aligned exactly with the doors of the train’s carriages.

The construction of Line C has promoted one of the biggest archaeological campaigns ever carried out in Rome. During the campaigns, about 100,000 m3 of ground have to be handled. Thousands of archaeological treasuries have already been discovered to date.

Mechanized Tunnelling

The new Line C is divided into 7 partial sections. Sections T3 to T6 are being built by the Joint Venture Metro C S.p.A. (Ansaldo Trasporti Sistemi Ferroviari S.p.A.; Vianini Lavori S.p.A.; C.M.B.; CCC-Consorzio Cooperative Costruzioni; Astaldi S.p.A.) with 4 identical Herrenknecht Earth Pressure Balance Shields with a diameter of 6.69 m each. Each section is driven by 2 parallelrunning TBM (Fig. 2). Upon termination of the sections T3 to T6, the 4 machines will have completed a stretch of 25.6 km.

The 2 machines S-409 and S-410 successfully reached the first milestone as early as October 2009. The 3,990 m long stretch to target shaft “5/4“ between the stations Parco di Centocelle and Mirti has successfully been excavated since June 2008 and/or September 2008, starting from Torrenova station and achieving average daily tunnelling performances of 11.1 and/or 12.7 rings and maximum weekly performances of 175 m and/or 172.2 m, respectively (Fig. 3).

The 2 sister machines S-479 and S-480 will also enter in this shaft. They have produced tunnel since September 2009 and/or June 2009 and are approaching the target shaft from Malatesta with up to 119 rings per week.

After dismantling, the machines S-409/410 and S-479/480 will tunnel the routes T3 and T4 from Malatesta to close to Venezia station. On this stretch the machines will cross beneath the famous Colosseum building with an overburden of 30 m.

Because of the space constraints in the target and launch shafts of Line C, the construction teams developed a special solution together with the machine supplier: The shield machine, including erector and screw conveyor, was completely assembled aboveground at the target shaft and then lowered into the shaft as a whole. In the same way, the complete shield machine was recovered from the shaft at the target shaft. This involves the installation of 4 bollards at the shield skin which allow lifting the complete shield using a 500-t-crane (Fig. 4).

Another 2 identical Earth Pressure Balance Shields made by Herrenknecht AG with diameters of 6.77 m each, are employed by Seli S.p.A. commissioned by Salini S.p.A. for the excavation of the northern turn-off of Line B, the future Line B1. The 3,000 m long stretch to be tunnelled, runs from Conca D’Oro station to the junction with Line B at Bologna station. Until today, the S-387 and the

S-388 have achieved best tunnelling performances of 12 and/or 14 rings a day.

Another Earth Pressure Balance Shield (S-554) ordered by Salini S.p.A. to be used for Line B1 with a diameter of 9.755 m was assembled at the factory and was scheduled to be delivered in January 2010. This shield machine will excavate the 1,000 m long section from Conca D’Oro station to Ionio station.

Launch and target shafts

As it is the case with many mechanically excavated tunnel projects, the launch and target situation in water-bearing soils presents a great challenge. To realize the tunnel projects in the Italian capital, short conventionally built tunnel sections were previously prepared for all 6 machines for the launch, and then the complete shields were introduced into these sections. Before mechanized tunnelling starts, the annular gap between ring segment and previously produced tunnel can be filled, sealing the tunnel construction towards the shaft.

For a save entering into the target shaft 5/4 of Line C, a connecting ring with an activatable target seal and pressure-tight flanged cover plate was the solution manufactured by MSD (Fig. 5). With the help of the lid, water intrusion can be prevented which might occur during the entering of the shield into the shaft. As soon as the shield is in the connecting ring shortly behind the cover plate, the sealing is activated. Now the gap between connecting ring and shield skin is tight, the cover plate can be removed and the TBM can be removed safely. The sealing must remain activated until the annular gap between shaft wall and ring segment is filled, which means that the tunnel building is sealed towards the shaft.

Machine technology

The design of the 4 identical Earth Pressure Balance Shields (6.69 m diameter) for Line C as well as of the 2 identical Earth Pressure Balance Shields (6.77 m diameter) for Line B1 is specifically adapted to the geological conditions of the route. An opening ratio in the cutting wheel of approx. 40 % allows a better flow of material into the excavation chamber, thus reducing clogging in the openings. The high opening ratio also increases the contact pressure of the tools which provides for a better penetration.

The cutting wheel which is rotatable in both directions is equipped with a total of 100 scraper tools, 16 buckets and an overcutter for soft ground. The discs can be accommodated in 13 casings and can be exchanged for rippers in line with the geology. The machines used to build Line C were equipped in the center with a center cutter, and the machines working on Line B1 with rollers. 2 rotors at the cutting wheel and 4 stators at the pressure wall provide for a good mixing of the excavated material in the excavation chamber together with the cutting wheel arms, and a good consistency of the material is obtained by injecting foam. With the help of conditioning, the torque required and wear-and-tear can be reduced to a minimum. The drive’s torque of 7,027 kNm with 1.46 rpm is generated by 9 hydraulic motors. The 4 axial piston pumps for the hydraulic motors are driven by 4 electric motors with a power of 400 kW each.

The shields are designed for a maximum pressure of 5 bar and are equipped with 19 double cylinders which generate a thrust force of 50,558 kN. The shields are additionally equipp-ed with 2 joints. One joint is an active control joint between front shield and center shield, and the other is a passive joint between center shield and tailskin. The 2 joints make it possible to realize the required narrow horizontal radius of up to 150 m.

The machines are also equipped with a bentonite control system to secure a constant pressure in the excavation chamber even outside working hours. If the predefined pressure in the excavation chamber falls, a pressure regulator automatically feeds bentonite from pressure tanks into the excavation chamber for compensation.

For the filling of the annular gap between soil and ring segment the so-called bicomponent system is being applied instead of filling the gap with conventional mortar and thick-matter-pumps. The bicomponent system involves, on the one hand, pressing into the annular gap a special mortar mixture (component A), and, on the other hand, the so-called accelerator (component B) through

6 openings at the tailskin end with the help of 6 eccentric screw pumps. After mortar and accelerator have mingled, the mixture becomes solid within a few seconds. This avoids subsidence which can occur, for example, if the mortar hardens too slowly.

Outlook

The 2 new metro lines in Rome, Line B1 and Line C, will contribute significantly to relieving the traffic situation in the Italian capital. For the mechanized tunnelling of more than 30 km of new metro line, the design of the Earth Pressure Balance Shields employed by the construction teams has proven to be the right solution for the challenges of this major infrastructure project. A continuation of the successful teamwork tunnelling of project owner, construction companies and machine supplier can be expected for the remaining sections to be built.