Bicomponent Synthetic Macro Fibres for Power Plant Tunnel

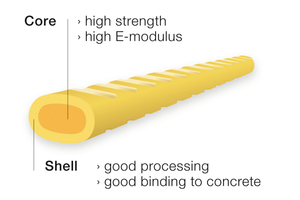

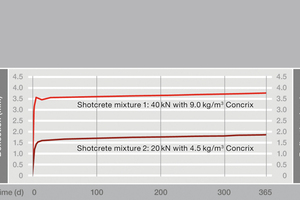

For years if not for decades steel fibre reinforced shotcrete has been applied in tunnelling with success. The various problems associated with steel fibres such as e.g. complicated handling owing to the high weight, balling during the mixing process, major rebound when spraying, wear affecting hoses and nozzles as well as corrosion and the increased danger of injury caused by projecting fibres were accepted due to a lack of alternatives. Bicomponent synthetic fibres have now been used for the first time for supporting purposes for a 6.6 km long power plant tunnel in Costa Rica (Figs. 1+2).

In...