Development of LDSMand HDSM Concept for Variable Density TBMs

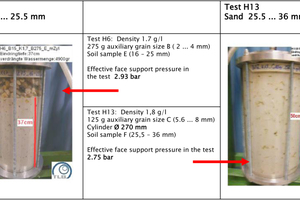

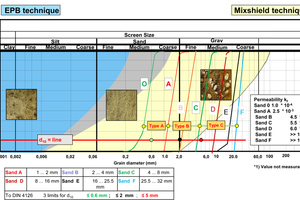

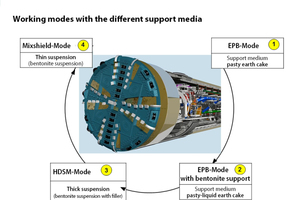

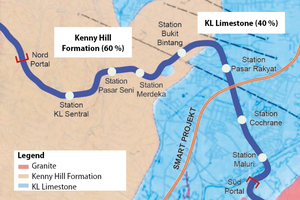

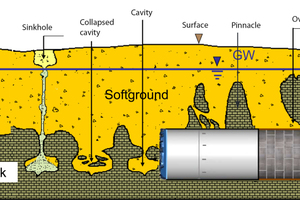

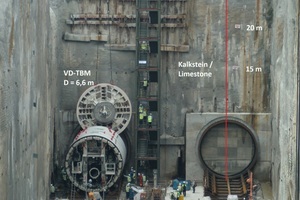

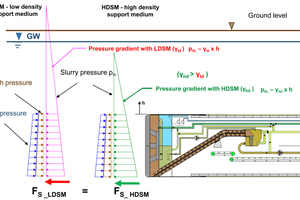

The capability to vary the density of the support medium between bentonite suspension and remoulded earth depending on the currently excavated ground is the essential feature of the Variable Density TBM (VD-TBM) from Herrenknecht. Especially for this type of machine, a support medium with an increased density has been developed, which reliably covers the transition from fluid to pasty – the High Density Support Medium (HDSM). On their first application for the Klang Valley MRT-Project in Kuala Lumpur, the VD-TBMs bored through karstic limestone in mixed face conditions with hard rock and soft ground. With the aid of the HDSM, the face support can be reliably maintained in otherwise problematic geology.

1 Introduction

Mechanised tunnelling in highly permeable ground with extremely heterogeneous geology along the alignment demands that the support medium used can reliably transfer the support pressure to the tunnel face.

Basically, the so-called multi-mode TBMs, which can be driven both in earth pressure and slurry support modes, are available for use in very changeable ground conditions. The changeover from earth pressure to hydro mode does however demand a technically elaborate conversion, which only permits the economic use of such machines in special cases. For the Klang Valley Mass Rapid...

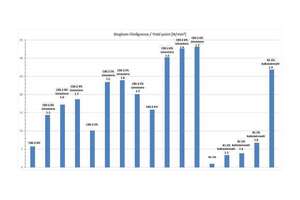

![Density development of HDSM [g/cm³] based on an LDSM B1 5% through the addition of limestone powder [g/1l LDSM]](https://www.tunnel-online.info/imgs/tok_1f4e3bf980179e43f28f13b423a562da/w300_h200_x400_y283_100844948_c03b02ed94.jpg)