Influence of Clogging on the Muck Transport in Shield Machines

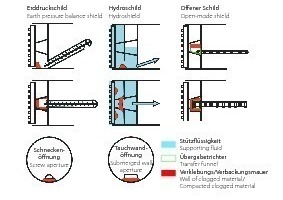

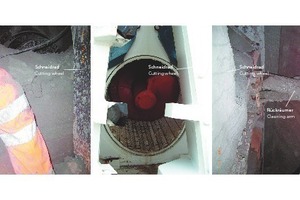

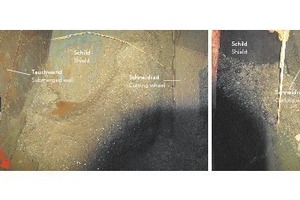

Shield drives in fine-grained clayey soil are frequently affected by clogging. Walls of clogged material represent a special form of this particular obstacle. Such walls can attain a high degree of strength and develop directly in the TBM’s material flow. The fact that these walls of clogged material exacerbate or even interrupt the direct path of the excavated material from the rear side of the cutting wheel to the follow-up conveying system makes driving especially difficult (Fig. 1).

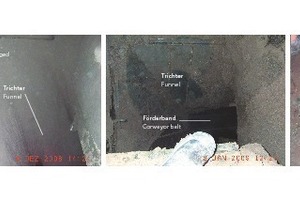

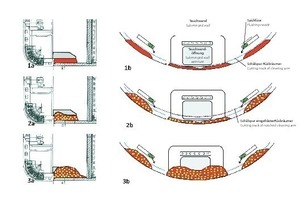

Conveyance of the excavated material from the cutting wheel towards the rear must therefore be carried out by a circuitous route with the material first being lifted by the cutting wheel and then transferred upwards. From there it moves backwards in the excavation chamber over the top of the walls of clogged material towards the suction inlet or in the case of the open mode EPB shield, towards the screw opening.

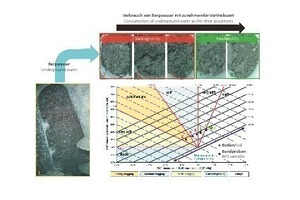

Such phenomena have been observed both in the case of unsupported open-mode EPB drives as well as in fluid-supported slurry shields, where the excavated material has to be transferred...