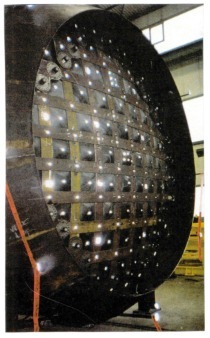

Mechanised Driving in Subsoil prone to Clogging, Part 1

Subsoil prone to Clogging, Part 1

Optimal harmonisation between the subsoil and process technology is of decisive importance in tunnelling. The topic is dealt with in 2 parts. In this first part the different driving methods are examined, the subject of clogging presented and it is demonstrated when the subsoil is actually prone to clogging. Towards this end, particular attention is paid to how the grain distribution of the excavated material has been altered through the excavation process compared to the original material.

Optimal harmonisation between the subsoil and the process technology is of decisive importance in tunnelling. The more frequently changing subsoil conditions can occur, the less their extent can be estimated and the harder they are able to be localised in advance so that the existing process technology has to be all the more adjustable. This especially applies to mechanised tunnelling so that 2 key questions must be answered in advance:

– Which subsoil conditions mainly prevail and how can the best performance be attained when using a particular process technology under these circumstances?

– Ho...