“A Model of Punctuality” – Erding Ring Closure S-Bahn Tunnel

Munich’s Franz-Josef Strauß airport in the Erdinger Moos is increasingly important as an economic factor for the region of Bavaria as well as a transfer location for passengers and freight all over the world. Passenger numbers have been increasing continuously for years and reached about 48 million in 2019. In order to keep up with the enormous growth, the state of Bavaria decided on a state-wide improvement of rail connections to the airport. The Erding Ring Closure is one decisive measure to build about 26 km of new line, composed of three independent sections, the Neufahrn Curve, the Gap Closure Erding and the Walpertskirchen Link.

Tunnelling Under the Airport

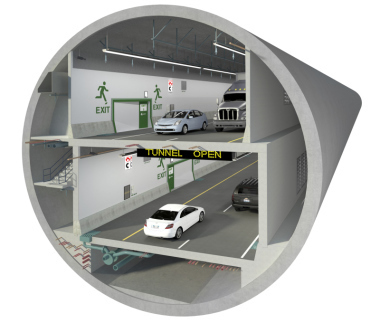

An underground extension about 1.8 km long from the airport in the direction of Erding to Schwaigerloh is currently under construction. The new S-Bahn transit link runs directly under the area of the airport. The tunnel has been under construction since 2018 and is scheduled to be completed by 2021.

“The client only allowed us a very tight time window for the construction of the tunnel in the airside area of the airport, which made 24-hour construction operation necessary over several months”, explains Dipl.-Ing. Denis Ultsch, project manager for engineering infrastructure in Munich for Porr GmbH & Co. KGaA. On the area of the eastern runway of the satellite terminal, a section about 250 m long had to be completed in nine months. “The use of a loadbearing scaffold for the roof slab formwork gained us enormous time savings in the area of the airport”, sums up Denis Ultsch. “The client even praised us as a model of punctuality.”

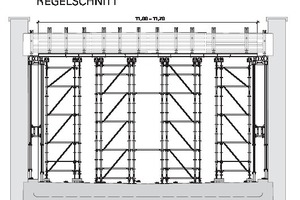

The tunnel is being built in cut-and-cover and, for the first 16 blocks under the area of the airport, in top-down construction. The rectangular section with a clear width of 11 m provides space for two railway tracks. From the airport boundary to the east, the tunnel continues for a length of 1555 m, followed by a 306 m long ramp structure. The standard section consists of a 1.15 m thick base slab of waterproof concrete, 55 cm thick side walls (also of waterproof concrete) constructed in front of the diaphragm walls, and a 1.10 m thick waterproof concrete roof slab. Porr had already involved formwork supplier Peri during the tendering phase and produced an alternative proposal to save time by supporting the formwork and concreting the roof slab in the first tunnel block under the airport on loadbearing scaffolding. In the further course of the tunnel, the use of a less expensive formwork unit was planned.

Loadbearing Scaffold Saves Construction Time

From block 2, Porr initially planned to use a mobile formwork unit for the entire area but then decided to construct the first 16 blocks on a stationary loadbearing scaffold, and had already set up five blocks by the time the team of master scaffolder René Schierstedt from Schäfer Gerüstbau GmbH arrived: “in order to further optimise the construction process, the stock of scaffolding material was increased by the blocks 6 to 16. This scaffolding work measure was undertaken by Schäfer Gerüstbau. The loadbearing scaffolds in blocks 1 to 5 continued in use as emergency support after concreting.”

After completion of erecting the loadbearing scaffolding in blocks 6 to 16, work could start immediately on laying out the VT 20 cross beams and the formwork surface. Formwork, steel fixing and scaffolding work sometimes proceeded in parallel on the site. One scaffold block section corresponded to one concreting section. The loadbearing scaffold for the slab formwork from the scaffold building system Peri Up Flex consisted of several free-standing individual towers, connected to each other at the head by yoke and cross beams through the conventional slab formwork. This formed the base for the later concreting work.

“Through the spatial system of a loadbearing scaffold, a relatively free-standing loadbearing construction could be built in advance without horizontal bracing”, explains Schierstedt. “The combination of the scaffolding system Peri Up and the engineering system Variokit for the construction of the mobile formwork units was quite simple for us. We have the two compatible systems in our own material stock. We have also been able to gain experience with the system on other structures and constructions. The essential advantage for us is that the Variokit building block system, similarly to the pure Peri Up scaffold system, is based on a metric grid pattern and has relatively similar assembly logic”, emphasises master scaffolder Schierstedt. “Normally loadbearing scaffolds are built with large and heavy steel beams, which are then welded to each other. This effort is unnecessary with Variokit because it can all be erected with universal connectors or cross connectors and simply disassembled after use.”

After a few days, the loadbearing scaffold was let down since the slab could support itself. After sufficient strength had been reached, the slab was backfilled. “During this process we carried out continuous performance measurements to observe the behaviour of the slab. The results were very satisfactory”, explains Denis Ultsch. “A calculated deflection on 5 cm is assumed and is therefore taken into account with a corresponding camber, like a little arch.” Finally, a deflection of no more than 10 mm was detected. The camber can be set to a maximum of 5 cm with the spindles on the loadbearing scaffold so that no additional elevation bars are necessary.

Extensive Engineering

“We investigated and simulated the working sequences of tunnel construction in advance, and defined and combined cycles in order to investigate how our formwork units could be coupled on this project”, is how Peri’s project manager Harry Maucher describes the solution-finding process that clinched the order. With the Peri concept, both the top-down and the cut-and-cover sections could be concreted using the same formwork units. One special feature was the integration of access stairs, working platforms and walkways of Peri Up working and protection scaffolding components. “We had not done this before”, says Harry Maucher. “We described this variant as an alternative proposal in our bid. The working platforms with fall protection round the edge could be integrated into the formwork units, which is an innovation. There is also a walkway connecting the left and right sides, providing the best possible working safety.”

The standard erection of the Variokit mobile formwork units takes five days; for the first erection, a Peri assembly supervisor was on site.

Planning Quality Ensures Construction Quality

“We have two different formwork solutions in use on this project”, explains Dipl.-Ing Steffen Krall, manager of the Peri Competence Center Infrastructure. “In order to construct the 6.50 m high and about 10 m long tunnel walls, a support trestle formwork capable of being extended crosswise and lengthwise was used. We planned this wall formwork and also the slab formwork units completely in 3D. All subsidiary works, which were also carried out with Peri formwork, are in 2D, including the loadbearing scaffolding. We already showed the mobile formwork units in 3D at the tendering phase in order that it would already be clear to the company Porr what Peri were planning in order to be able to carry out the work quickly and economically. In the 3D visualisation, we can show all construction situations on site spatially, which considerably simplifies understanding and assessment. In this way all important decisions could already be made at this early stage, such as measures for fall protection or measures to optimise the construction sequence and access routes.“

Positive Intermediate Conclusions

In professional collaboration, both of the involved partners succeeded in developing rapid processes with little waste at all levels of the construction work. The direct vicinity to Munich Airport lead to restrictions for construction works concerning cranes and access to the site in the area of the runway. Porr also has high standards of working safety, which were thoroughly implemented here.

“It was important for us that the formwork and loadbearing scaffolding systems are thoroughly and technically well planned, because they have to undergo a very stringent test from the checking structural engineer”, emphasises Ultsch. “The checking engineer was on site for all acceptances of loadbearing scaffolding. This showed how important it was for the preliminary planning to be appropriately well thought-out, and only a few questions arose during erection.” For Schäfer Gerüstbau, it was decisive that scaffolding material from Peri Up could be integrated into the slab formwork units. “The collaboration between the companies Porr and Peri and ourselves was very good, simply because we had prepared ourselves as well as possible during the preliminary meetings with Peri”, emphasises René Schierstedt. “This quality then continued through the initial meetings with Porr, covering questions such as crane availability, material at the assembly location or erection sites.”