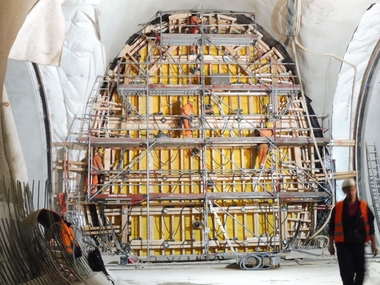

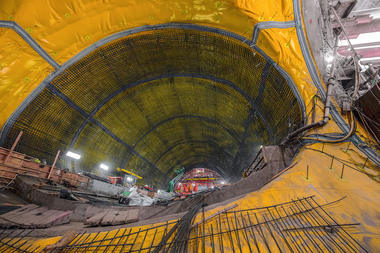

Lötschberg Base Tunnel, Second Tube: Automated Cost Optimization of the Inner Lining

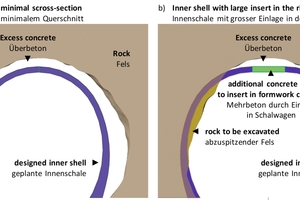

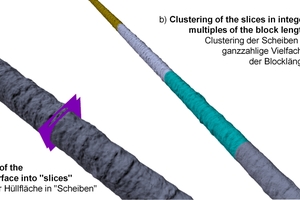

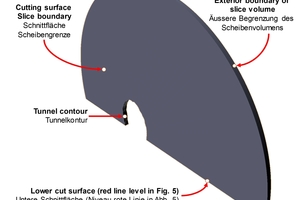

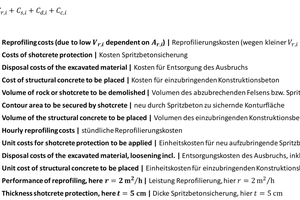

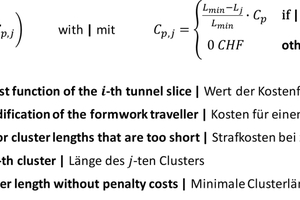

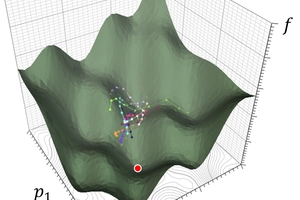

To realize the integrated synchronized timetables in long-distance traffic and to increase the capacity in freight traffic between Brig and Bern, the two-lane extension of the Lötschberg Base Tunnel (LBT) is necessary. This demands the installation of an inner lining over 14 km in the second LBT tube. Considering the excavation profile available, a skillful choice in the sequence of formwork carriage geometries (FCGs) can lead to optimization of the concrete volume to be installed, the feasibility of the build and the construction sequences. In the sense of a “proof of concept”, mathematical optimization algorithms are used to find a cost-optimal sequence of FCGs for a defined tunnel section. The article in tunnel 5/2021 describes the chosen approach and the results of the cost optimization.

1 Project Overview

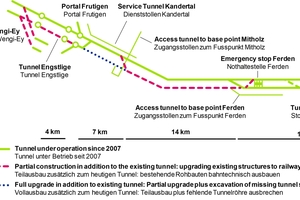

The Lötschberg Baseline – comprising the 34.6 km long Lötschberg Base Tunnel (LBT) and the 2.6 km long Engstlige tunnel in the north – has been in operation since 2007. Due to limited financial resources during construction, the Lötschberg Baseline could not be completed over its entire length with two separate single-track tubes.

Currently, only the east tubes are in continuous operation (Fig. 1). The west tube of the LBT has been upgraded in the south over almost 14 km between the Raron south portal and the Ferden emergency stop. However, from the Ferden switch point to the...