Thun Flood Relief Tunnel, Part 2 –

Compressed Air Operations with the Hydro-Shield Method

The roughly 1,200 m long Thun flood relief tunnel was driven in silty-sandy gravels from July 2007 to April 2008. The highly abrasive geology led to the cutting wheel tools being subjected to substantial wear, resulting in considerable maintenance work. Altogether 438 working hours were spent in overpressure at up to 2.6 bar. However, on account of the decompression tables specially devised for the site to allow the crew to exit under oxygen no decompression complaints were recorded. In tunnel 7/2008 pp 27 ff. the challenges posed by the Thun flood relief tunnel project were presented.

Need for Compressed Air Work

In the case of the hydro-shield method accesses for the recovery of obstacles, which cannot be removed by means of the cutting wheel as well as for checking and replacing the extraction tools are necessary (Fig. 1). Obstacles can be anchors, steel girders and piling reinforcements from former excavation pits as well as larger pieces of timber embedded in the subsurface.

As far as the Thun Flood Relief Tunnel was concerned over some 50 m of the drive in the proximity of the station square the anchors for an underground parking facility were situated slightly above the roof. Fortunately these anchors had been produced according to plan at the time so that none of them actually jutted out into the tunnel cross-section. No obstacles belonging to former excavation pits were otherwise encountered along the entire driving route. Compressed air operations reduce the rates of advance and should be avoided if possible. As a result while driving the Thun Flood Relief Tunnel the extraction tools were checked towards the end of the shift at least once a week. On account of the abrasive geology the interval was shortened at times. The tools include the cutters, the reamers and the roller bits. These in each case consist of a retaining fixture welded to the basic construction as well as a replaceable element. The cutters and reamers are provided with hard metal inserts and welded-on parts. Damage to the retaining fixtures must be avoided as far as possible for they can only be repaired through extensive welding operations under compressed air. In Thun it was possible to avoid damage to the retaining fixtures entirely thanks to intensive checks and the great attention paid on the part of the crew. Correspondingly the cutting wheel was also in a very good state when it entered the target pit. Risks during Compressed Air Work Compressed air workers are subjected to a major heat load on account of the high temperatures, the humidity and reduced perspiration so that the consumption of fluids is extremely important.

The nitrous gases and ozone, resulting from welding and burning, have a far more harmful effect on health under overpressure than under atmospheric conditions. Consequently an air supply independent from the surrounding air must be set up for the welders and their assistants in addition to ventilation for the work place and the local smoke removal system. Toxic vapours from contaminated earth can lead to respiratory complaints and call for breathing masks to be worn. Further risks result from the heavy work load, the restricted communication between lock attendants and compressed air workers, injuries caused by climbing and hoisting and last but not least by blow-outs, which necessitate sudden decompression when then are losses in pressure.

Operation Concept

Legal Position

For compressed air operations in Switzerland just like for all other work the “Ordinance on Accident Prevention” and the “Building Worker Ordinance” primarily apply. The “Ordinance governing technical Measures to prevent Accidents and industrial Illnesses given Work under Compressed Air” dating from 1961 must also be observed. This is actually outdated in certain sections and no longer reflects the state of the art, although it is still applicable. For example the code only contains tables for divers resurfacing and not for actual compressed air operations.

In practice admittedly the current Swiss ordinance is applied, however parts of foreign regulations are also applied, which are stricter. This is carried out after mutual consultations with the SUVA. As a consequence generally the German compressed air ordinance from 1972 is applied. This code is 36 years old and no longer complies with the latest state of the art either. As the compressed air ordinance applies to relatively few people, Germany has responded by including the ordinance in the RAB 25 (Rules for Industrial Protection on Con-struction Sites) by updating the compressed air ordinance to comply with the state of the art in 2003 rather than undertaking its lengthy revision.

The German compressed air ordinance and the RAB 25 describe the various medical, technical and operational safety measures against physiological dangers resulting from overpressure. The medical measures for instance include the medical prior check-up, age limitation, medical supervision as well as keeping health records. The most important operational measures include the restriction of overpressure, disclosure requirement, tests, the appointment of experts, instruction and carrying out trial dives, keeping a diving log and the production of an operating manual. The technical measures include separate locks for staff and materials, a sufficiently dimensioned compressor station, an emergency power supply, a redundant air feed, filter units for oxygen supply, communication lines between all important operating points as well as suitable fire protection systems.

Putting the legal Principles into Practice

The operating concept for compressed air operations during the building of the Thun Flood Relief Tunnel is based on experiences made with the projects Skymetro at Zurich Airport, the SBB rail tunnel Zurich–Thalwil and the Oenz-berg Tunnel on the SBB’s new Mattstetten–Rothrist line. The RAB 25 was taken into consideration in addition to the outdated Swiss and German codes. In addition the “Specification for the safety-technical Documen-tation of Underground Workings under Compressed Air” of the SUVA served as a basis.

The decompression with compressed air and the diving tables were compiled by Dr. med. Bühlmann of the Univer-sity of Zurich for the mentioned projects. The application of medical oxygen as decompression gas is nowadays state of the art and is compulsory in Germany. Compressed air is only permitted for short accesses or in cases of exception. As a result the JV decided to use medical oxygen for transfers. As oxygen displaces nitrogen from the body experience has shown that fewer complaints occur with this decompression gas.

Two acknowledged experts were also called on in the shape of the compressed air specialist Dr. med. Karl-Peter Faesecke, Hamburg/D and Claus Mayer from the Nordseetaucher GmbH, Ammersbek/D for consultation and working out the operating concept. Whereas the SUVA in Switzerland does not prescribe the provision of a treatment room on the spot, this is compulsory in certain European countries and in the USA. In Switzerland it is compulsory to transport compressed air workers with decompression complaints to Basle or Lausanne via the Swiss Rescue Flying Service REGA in order to treat them there in the only 2 existing pressure chambers. A treatment room was also available at the Zurich University Clinic until the late 1990s, which has been closed down in the meantime for cost reasons.

A treatment room present on the construction site would further strengthen the confidence of the staff in the safety precautions. The human organism partly saturated with nitrogen, in which bubbles of gas have developed (symptoms of the compressed air illness) should not be exposed to additional vibrations like those caused by a vehicle or helicopter because this causes bubbles to multiply. A treatment room on the spot can also be used for trial transfers.

Compared to external clinical facilities the experience medical staff on the construction site is familiar with the specific symptoms and indications of illness resulting from a drop in pressure after working in compressed air and can immediately introduce therapy suited to the individual case. The threshold of the members of staff as far as consulting the medical facility on the construction site is substantially lower than compared to an external one. They are able to remain in familiar surroundings and are looked after by people they know.

After consulting with the SUVA the JV decided not to establish a treatment room. In order to be in a position to avoid decompression complaints as far as possible, the transfer times were set as conservatively as possible.

In collaboration with the 3 German language-speaking countries Germany, Austria and Switzerland (D-A-CH) the joint drawing up of a basic paper pertaining to the medical and technical preparation of appropriate legal regulations with the countries in question is being worked out. It would be most welcome if this project were encouraged especially with respect to the question of the necessity of providing a compressed air chamber on the spot.

Decompression Tables

Special tables were worked out by Dr. med. Karl-Peter Faesecke for the compressed air operations for the building of the Thun Flood Relief Tunnel because the Swiss ordinance contains no decompression tables for transfer with oxygen and the German ordinance only obsolete ones. On account of the altitude, the degree of difficulty of working under compressed air in the tunnelling machine and the lack of a possibility for recompression on the spot the maximum working time in overpressure was restricted to 3 h and the longest period of transfer to 1 h (Fig. 2).

Depending on the pressure and the time human tissue acquires additional nitrogen saturation given exposure to overpressure. This nitrogen surplus can be expelled via the lungs within narrow physiological limits by the organism in a controlled manner during the transition to normal pressure. In this connection certain pressure stages for minimum periods as laid down in the tables have to be adhered to, during which oxygen must be breathed in as decompression gas.

Up to a working pressure of 1.9 bar, a period of max. 180 min is permitted and correspondingly the pressure stages for periods spent in overpressure are provided at 30, 60, 120 and 180 min (Fig. 3). In the case of working pressure in excess of 2.0 bar the period is restricted to 120 min in order to avoid decompression complaints as far as possible (Fig. 4).

The lock attendant records the time from the moment of entry and constantly informs those persons working under overpressure about the time reserve, for the maximum period must on no account be exceeded. In the case of working pressure of 2.4 bar and a stay period of 110 min the pressure stages for the next highest stay period of 120 min are applied for the outward transfer. During the first 8 min the pressure for the workers seated in the main chamber decreases from 2.2 to 1.0 bar. Subsequently they put on masks and breathe in medical oxygen during the next 21 min. In the case of stay periods in excess of 15 min the masks are taken off during the phase from 1.0 to 0.5 bar. During this recovery phase any movement of the masks when breathing in the oxygen and the undesired escape of oxygen into the lock should be avoided. Following a further 21 min the masks can be removed and the pressure reduced to 0 bar. This results in an outward transfer time of 52 min and a total working period of just under 3 h in overpressure. The members of staff concerned receive a bonus as compensation for the compressed air operations in the same way as happens with working underground.

The Safety Plan

The safety plan represents an invaluable aid for excavation work. The foremen record the latest stage reached by the drive and in this way can assess which obstacles with which overburden are being undercut. In the supporting pressure log the required supporting pressure in the excavation chamber for a low and high groundwater level is to be found. The necessary pressure of the air cushion is obtained by calculating the supporting pressure, which is worked out from the elements geology, overburden, groundwater level as well as permanent (e.g. houses) and alternating loads (e.g. traffic). This is worked out in 28 different cross-sections. In the interim the values for setting the pressure regulating system on the tunnelling machine are interpolated. Prof. Markus Thewes of the Ruhr University in Bochum/D and the Ingenieurbüro Zerna from Bochum/D were commissioned to compile the supporting pressure calculations.

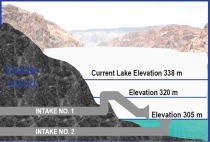

In order to undertake compressed air operations the bentonite slurry in the working and extraction chambers has to be lowered. The values for the supporting pressures and the blow-out safety for the various lowering levels are contained in the safety plan. Towards this end a distinction is made between levels of one-third, half, two-thirds and full. Usually the level is lowered by half for tool checks whereas for changing the extraction tools the compressed air level is reduced to two-thirds. The level is only completely lowered should repairs on the rock crusher be required – something that was never necessary in Thun.

The safety plan also indicates when inward transfers are not permitted. This may be owing to calculations regarding supporting pressure and blow-out safety or undercutting infrastructural buildings such as a railway line or road underpasses posing high demands on operating safety.

Staff Requirement for Compressed Air Operations

Basic Principles

Teams comprising 3 +1+1 are required for the uncomplicated and safe application of an operation under overpressure. The duties are divided up as follows:

- 3 compressed air workers/technicians: execution of work, assistants, communication to lock attendant - 1 lock attendant/chamber operator

- 1 team leader/certified supervisor.

The lock attendant is responsible for transferring persons into and out of the working chamber. He operates the lock from the outside and keeps a lock log (Fig. 5). He constantly observes the persons being transferred during their inward journey. All members of staff must follow the instructions of the lock attendant, also his superiors. Two certified supervisors have to be present on the construction site, the team leader and his permanent deputy.

Execution

The construction site leader or his deputy as certified supervisors headed the compressed air operations. The lock attendant and the compressed air workers were recruited from the JV’s excavation crews. Lock attendants must be reliable and be able to depend on great confidence among the shift members. In addition to the 2 foremen 2 tunnel workers were trained to be lock attendants. All members of staff had to undergo an industrial medical preliminary examination carried out by the doctor approved by the SUVA – Dr. med. Thomas Toth in Thun. Three engineers, 1 foreman and 10 workers were available for compressed air operations. Prior to the first assignment all members of staff had to undergo a trial transfer. For even after a successfully accomplished preliminary examination it can be the case that someone cannot withstand the pressure adjustment or does not feel comfortable for psychical reasons in the narrow locks. After all compressed air operations have to be carried out on a voluntary basis. It would be wrong to compel someone to take part for the members of staff must be able to depend on each other as a team of 3 in the compressed air.

Prior to starting the driving work the personnel as well as the shield and erector operators were introduced on site to the compressed air operations during 3 half-days and obtained the certificate as “Technician for Work in Overpressure”. Claus Mayer took over the operational and technical part on 2 half-days whilst Dr. med. Karl-Peter Faesecke provided an insight into the industrial medical part on the third half-day.

Installations for Compressed Air Operations

In order to enter working areas with a compressed air atmosphere persons and tools have to pass through locks, in which the air pressure is increased in the working area. Given an overpressure in excess of 0.1 bar this is known as working in compressed air. In Thun the max. required overpressure during inward transfer amounted to 2.6 bar. The personnel lock with 3.0 bar operating pressure and a testing pressure of 4.5 bar comprises an entrance and an main chamber (Fig. 6). In the case of the machine used in Thun the 2 chambers are set up next to each other and connected by means of an intermediate door.

The compressed air unit included 5 electric compressors, which supplied an available air quantity of 72 m³/min, roughly twice as much as the excavated cross-section (Fig. 7). The compressed air was temporarily stored in 4 air tanks with a total capacity of 42 m³. Once the compressed air was produced water and oil had to be immediately removed to which end refrigerant driers as well as oil, water, particle and active carbon filters were used. The driers and filter lines were assembled redundantly in the compressed air lines within the tunnel for safety reasons. As compressed air also had to be produced in the event of a power cut, emergency aggregates with network failure automatic systems were installed.

A mobile oxygen system was set up on the tunnelling machine as continuous operation could not be assured. This system consisted of respiratory units as well as oxygen supply and air breathing supply hoses (Fig. 8). Prior to a compressed air operation the system was driven to the back-up with medical oxygen.

Progress made by the Compressed Air Operations

Preparation

The compressed air operations were carried out in accordance with the pattern shown in Fig. 9. During the preparatory phase the emergency services – compressed air doctor, local doctor and REGA were informed. In this connection the REGA advised the availability of at least 1 treatment room in Basle or Lausanne. If there was not then the compressed air operations were postponed until some later point in time. In addition the material was made ready and checked and the necessary working pressure established on the basis of the required submerged level.

Inward Transfer

The lock attendant checked the fitness of the staff, the working pressure, the lock times etc. and registered them in the log. The connection with the persons transferred was established by fixed-line telephone. The compressed air doctor could be contacted directly from the lock via this line or the emergency services summoned. In the event of a breakdown the emergency telephone was available (Fig. 10).

Prior to the inward transfer the supporting fluid was replaced by fresh bentonite so that an as good as possible filter cake can be built up at the face and compressed air cannot escape. Then the supporting fluid was lowered in the extraction and working chambers and the required supporting pressure set via the compressed air regulating unit.

Transferring too quickly from normal to overpressure can lead to acute complaints such as earache, headache and toothache as well as a loss of balance. In addition any obstruction to the pressure balance (e.g. in the event of a cold) affecting cavities filled with air (e.g. the sinuses, tympanic cavity, gastrointestinal tract and bad dental fillings) can cause complaints. As a result the lock attendant must test each member of staff for pressure balance before the inward transfer. The air we breathe is a mixture with the main components oxygen and nitrogen. The molecules increase in volume owing to compression. As a result when there is a surrounding pressure of 2 bar there are three times as many molecules as there are at atmospheric pressure. Consequently the increase of oxygen has no effect on the human body. The body tissue is provided with the oxygen required for the metabolism. This carries nitrogen along with it. The nitrogen dissolves physically in all tissues, for these consist of water. The solubility depends on the situation of the circulation, the pressure, the duration of exposure, the load and the specific solubility. At a new pressure level saturation of all body tissues with nitrogen starts, which can result in complete saturation. Towards this end there are substantial differences in the capacity of different tissues to absorb nitrogen.

Execution of the Compressed Air Operations

After the first access within the scope of a multi-shift compressed air assignment, the extraction chamber and the cutting wheel must first be cleaned prior to work being resumed. In order to make it safe to move around the chamber platforms and ladders have been attached to corresponding fixtures. Then tool checks or exchanges (Fig. 11) could be undertaken. In this connection, the link man in the lock’s main chamber can turn the cutting wheel. Prior to underpassing the railway the tools had to be checked under a former tank storage. However, immediately after the pressure wall valve was opened a strong oily smell was determined causing the team to exit. It was then possible to carry out the check as required wearing special breathing masks. Cutters and reamers are checked visually and roller bits with the help of a template (Fig. 12).

The highly abrasive geology led to the tools being worn far more than was originally expected. For checking and replacing tools altogether 438 working hours were spent under overpressure of up to 2.6 bar. Thanks to the intensive and precisely carried out checks damage to the tool retaining fixtures could be avoided. In a sector in sandy gravel the tools were seriously worn after only a few metres after being successfully changed. Over 5 working days, 42 cutters, 10 roller bits and 8 reamers were replaced during 3 compressed air shifts. In order to gain time compressed air technicians from the Nordseetaucher GmbH were available for weekends, who could be on the spot within 24 h. Possible welding jobs under compressed air were also undertaken by these specialised workers as the JV’s team were not trained or equipped for the task.

The around 170 kg heavy roller bits had to be lifted by chain hoists into the material lock from the ring construction sector. In the working and extraction chambers the tools could also be lifted by chain hoists into the correct position. Depending on the state of the bolts and the wedges it took a good 120 min to change a bit – something corresponding to a maximum working time under compressed air given working pressure exceeding 2 bar.

Given a number of successive compressed air accesses the bentonite level in the extraction chamber was not raised on each occasion so that time was not lost for dismantling the ladders and platforms as well as cleaning on the next access. When the filter cake starts to dry out and the compressed air escapes into the soil the face has to be moistened with bentonite again between 2 accesses in order to assure stability. In Thun the air consumption amounted to roughly 10 to 15 m³/min given a sealed face. If this rose to over 30 m³/min the bentonite level was again raised. If a high amount of air is blown in the loud noise makes it difficult to communicate.

Rescuing injured Persons in Overpressure

Self-rescue is not possible in the event of accidents in the working or extraction chamber under overpressure. As a result the 2 other members of the 3-man team are obliged to rescue the injured person and appraise the situation in accordance with an approved scheme (Fig. 9). Should the accident not be serious the injured worker is taken care of in the working chamber or the man lock. In order to be able to fulfil efficient First Aid duties the members of staff were obliged to take a course with the Thun Samariterverein and shortly before the excavation commenced rescue drill was carried out supervised by experts.

In the event of a serious accident the injured person must be outward transferred after consultation with the compressed air doctor, which can be extremely difficult on account of the confined space conditions. In this connection it must not be underestimated that bleeding under overpressure on account of diluted blood is substantially stronger than under atmospheric pressure. Depending on the injury further helpers can be inward transferred should the compressed air doctor advise this move. Following decompression he is then transported into the open and to hospital in accordance with the compressed air doctor’s instructions.

Three members of the STS AG rescue service attended SUVA’s “Industrial Medical Check-up for Compressed Air Workers” course so that any possible rescue assignments in the overpressure chamber would have been assured professional medical care 24 h per day.

Outward Transfer

Outward transfer takes place under normal conditions only via the main chamber (Fig. 6). Towards this end the entrance chamber always remains pressureless so that First Aid helpers can obtain access at any time. The dissolved gases must be released via the circulation system and the lungs during the outward transfer, something that needs time. The duration of decompression depends on the working depth and the time spent under compressed air as well as the decompression gas (air or oxygen). Decompression takes place in stages and is supported by oxygen under 1 bar (Fig. 13). In this way the drop in pressure is increased and the decompression time drops by up to 50 %. As far as nitrogen saturation is concerned, the discharge procedure must not be too fast. Some 24 h elapse until all nitrogen has left the body.

The body tolerates a certain nitrogen over-saturation. If the decompression is insufficient or if it takes place too quickly, bubbles of nitrogen can form in the body. The gas emboli that result in this way are the commonest cause of damage resulting from working in overpressure. Furthermore the release of gases within the cells can cause temporary or permanent damage to the tissues. They can occur while the pressure is being decreased or even hours afterwards.

In principle all forms of decompression complaints (see Box) must be treated at one with recompression and breathing oxygen. This takes place in a treatment room given a minimum pressure of 1.2 bar for minor cases.

The frequency of decompression illnesses can be significantly reduced by applying oxygen decompression. However, the prerequisite for such results is to be able to handle oxygen safely. Continuous analysis of the chamber air as a primary fire protection measure is just as essential as absolutely adhering to the exposure limits for oxygen in accordance with pressure and time. The inclusion of a specialised authorised doctor in monitoring exposure to oxygen also diminishes the danger of oxygen poisoning should the exposure limits be exceeded in cases of emergency.

In spite of all precautionary measures it can be the case that illness phenomena occur during the outward transfer. Should someone display such decompression complaints the outward transfer procedure must be halted at once and the current pressure stage adhered to until the symptoms have disappeared. Should this not be the case after a few minutes the pressure in the lock has to be restored to its previous level. The lock attendant reports to the compressed air doctor and transfers him through the lock with particular care after consulting with the doctor. Subsequently corresponding treatment methods such as First Aid or transportation to the treatment room for recompression have to be undertaken.

After outward Transfer

After the outward transfer physical exertion should be avoided if at all possible for at least an hour. Should symptoms of decompression complaints occur after the work is completed then the members of the team and the compressed air doctor must be informed in accordance with the procedure (Fig. 9). The latter decides whether inward transfer should again be carried out followed by gradual outward transfer on the construction site or whether the REGA should be required to transport the person to a treatment room in Basle or Lausanne.

90 % of complaints occur in the lower extremities, above all in the joints but less in the muscles. The flow of blood to the legs is restricted by having to sit in the confined spaces of the man lock. The blood remains stationary and starts to flow again when one moves following the outward transfer. Only then is pain noticeable.

Experience shows that it can take up to 14 h until the complaints actually occur. It can be all of 23 h after the outward transfer until a visit is paid to the stationary treatment room. Compressed air operations are avoided on Friday prior to embarking on the trip home as far as possible. The German compressed air ordinance prescribes that a waiting period of 90 min has to be adhered to given work in compressed air with a working pressure in excess of 1 bar prior to embarking on a journey from the workplace that lasts longer than 12 h. Should decompression complaints nonetheless occur the compressed air workers are provided with an emergency pass.

Assessment of the Compressed Air Assignments

Fig. 14 displays the transfers for the 3 most frequent pressure ranges – 1.6, 1.9 and 2.2 bar. The stay period in overpressure is recorded on the x-axis and the outward transfer time on the y-axis in minutes. All exposures have remained above the prescribed outward transfer axis, i.e. no mistakes were made while operating the locks – praise indeed for the lock attendants. In addition it is evident that the theoretically possible maximum times of 120 min at 2.2 bar as well as 180 min at 1.6 and 1.9 bar were fully exploited. Formerly compressed air tables only took into account the decompression aspect given a maximum stay but not the ultimate ability to work under pressure of the compressed air workers. During the production of the Thun Flood Relief Tunnel this was successfully altered so that no compressed air complaints occurred.