Adaptive Planning of Grouting Measures in Tunnelling Using Artificial Intelligence

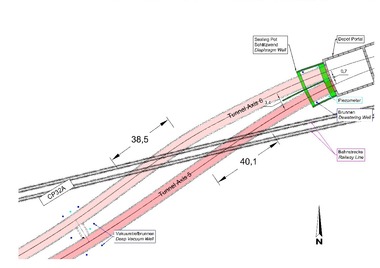

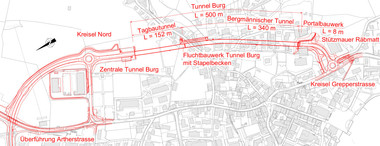

In the course of tunnel drives, pre-support measures can be necessary to waterproof or consolidate the surrounding ground. Since such measures can sometimes drastically slow the advance rate, their efficient planning is of great significance. One frequently undertaken measure is grouting, which can be carried out flexibly with relatively simple machinery. Alongside this flexibility, continuous adaptation of the parameters as the work proceeds must also be possible. This may mean regular adaptation – both of drilling patterns and depths as well as grouting parameters, grout materials or stop criteria.

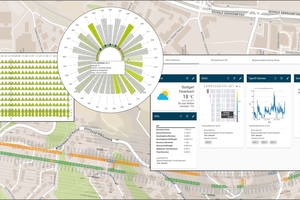

Real-Time Use of Drilling and Grouting Data for the Construction Process

Digital data logging systems have become increasingly prevalent in drilling and grouting technology. These have only been used until now for documentation in connection with quality management. In the course of the AVANT project, the intention is to make use of this data in order to be able to implement tunnel drives and the associated grouting work still more efficiently and thus more economically. The cantral idea is to immediately process drilling and grouting data underground and use it as the tunnel proceeds instead of just using the data for documentation purposes. This entails connecting the individual steps to create a dynamic real-time process. Artificial Intelligence methods are to be used on several levels:

Geological models created automatically based on drilling data to characterise the rock mass regarding the practicality of grouting

Grouting models, which for example can be derived from typical pressure-quantity parameters for the assessment of grouting success

The possibilities of this form of data exploitation using Artificial Intelligence are currently being investigated in the research project AVANT. Altogether five companies and research institutes from Germany and Austria are involved:

STUVA e. V., Cologne

eguana GmbH, Vienna

geoteam Ingenieurgesellschaft GmbH, Dortmund

Montanuniversität Leoben

Züblin Spezialtiefbau Ges.m.b.H., Vienna

The project is being financially supported from 2020 to 2022 by the German Federal Ministry for Economic Affairs and Energy (BMWi) and on the Austrian side by the Austrian Research Promotion Agency (FFG).