Fehmarnbelt Tunnel: 10 000 Tons of Special Formwork Delivered

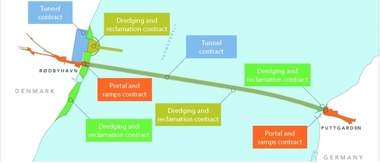

With a length of 18 km, the Fehmarnbelt Tunnel will be the longest immersed tunnel in the world and is considered one of the largest infrastructure construction sites in Europe. Peri developed a formwork concept for the central production of the standard tunnel elements. With the last of a total of twelve ships, the delivery of the customised special formwork from the central formwork supplier for this project was completed in spring 2023 with a volume of more than 10 000 t.

Fehmarnbelt Tunnel: Visualisation of the casting hall in the tunnel element factory

Fehmarnbelt Tunnel: Visualisation of the casting hall in the tunnel element factory

Credit/Quelle: Femern A/S

After its planned completion in 2029, the Fehmarnbelt Tunnel will connect Denmark and Germany for road and rail traffic. The immersed tunnel with a total width of 45 m consists of concrete elements with five tunnel tubes, two of which are two-lane tubes for motor vehicles, two are single-lane tubes for rail traffic and one is a service and escape tube. In total, Peri is supplying formwork material for 79 standard tunnel elements, each 217 m in length and 73 000 t in weight.

The complete formwork material was delivered to the working port with a total of twelve ships and over 250 trucks

The complete formwork material was delivered to the working port with a total of twelve ships and over 250 trucks

Credit/Quelle: PERI SE

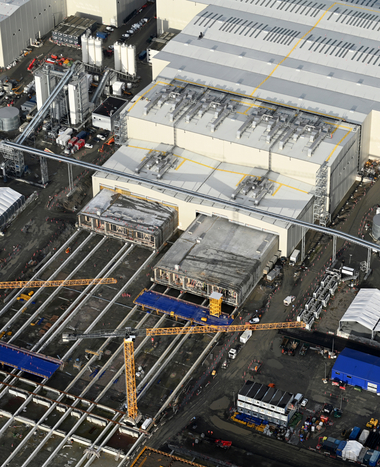

Assembly of the delivered parts at the site in Denmark – in total, Peri supplied formwork material for 79 standard tunnel elements, each 217 m long and 73 000 t in weight

Assembly of the delivered parts at the site in Denmark – in total, Peri supplied formwork material for 79 standard tunnel elements, each 217 m long and 73 000 t in weight

Credit/Quelle: PERI SE

Incremental Launching Method With Nine Concreting Sections

To make the customer requirements a reality, the Peri engineers decided on an incremental launching method with nine roughly 24 m long concreting sections. The solution forms the foundation for monolithic concreting, which reduces the risk of water penetration during tunnel operation. In addition, each tunnel section will be concreted without ties in the outer walls. At the same time, the approach means considerable savings in material and labour costs, thereby reducing the use of raw materials, among other things.

The special steel components of the formwork were produced in Poland, Italy and at the Peri plant in Weißenhorn, Germany. The delivery of the entire material with twelve ships and over 250 trucks in accordance with requirements and deadlines were made possible through close coordination with the client. At the end of February 2023, Peri already celebrated the delivery of the one millionth part to the construction site of the Fehmarnbelt Tunnel project in Denmark.

Assembly and Immersion of 79 Standard Tunnel Elements

Work is done both on land and at sea in Rødbyhavn. The tunnel elements are produced in a large factory with the size of 140 football fields. The standard tunnel elements are produced on site in five separate production lines, in halls built especially for the project combined with a working port. Each of the 79 standard elements is composed of nine concreting sections with a width of 45 m and a height of 9 m. Around 3000 m3 of concrete are used per concreting section, resulting in a weight of more than 8000 t each.

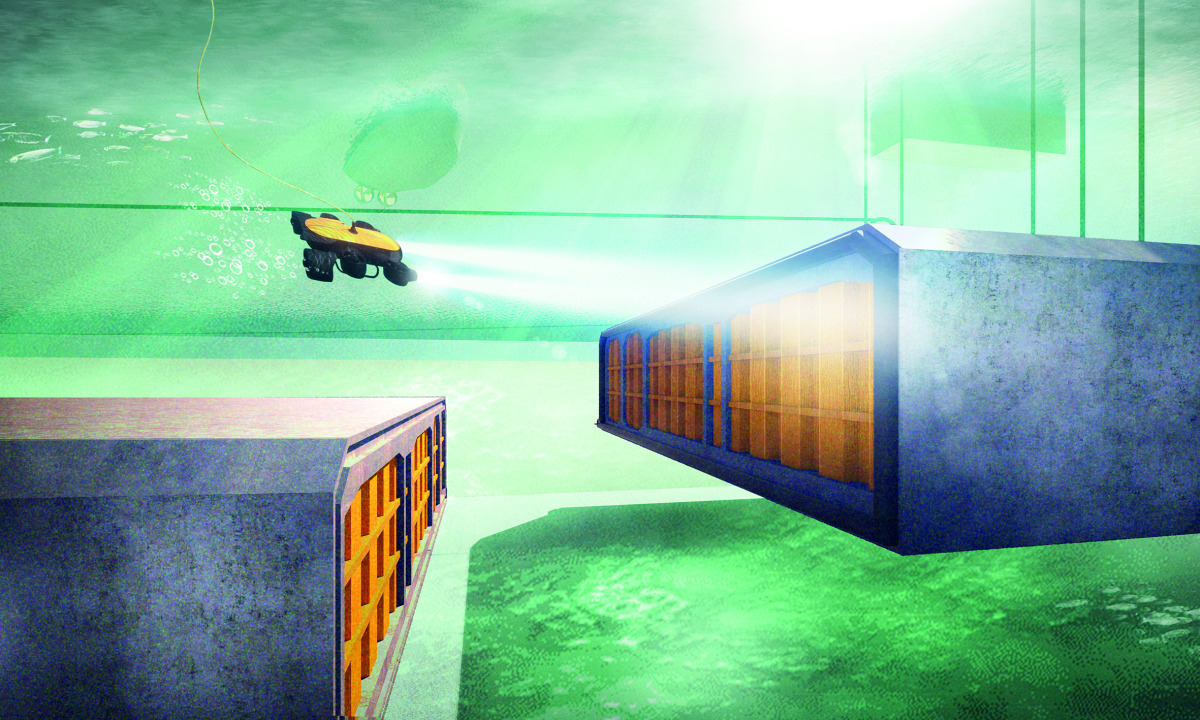

After the concreting process, the elements are fitted with bulkheads at both ends and sealed tightly. The basin containing the elements is then flooded with water. Thanks to the tight seal, the elements float and can be transported to the location in the Fehmarnbelt, where they are immersed in the tunnel trench and connected so they are watertight.

Visualisation of the immersion and connection process: Each of the 79 standard elements is composed of nine segments with a width of 42 m and a height of 9 m and includes four traffic tubes and one rescue tube

Visualisation of the immersion and connection process: Each of the 79 standard elements is composed of nine segments with a width of 42 m and a height of 9 m and includes four traffic tubes and one rescue tube

Credit/Quelle: Femern A/S