Gotthard Base Tunnel: Stage reached by Work

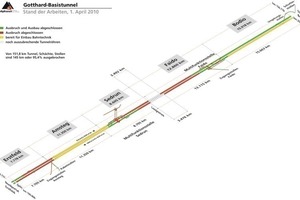

At the end of March 2010, a total of 144.8 km or 95.4 % of the altogether 151.8 km long tunnel system for the Gotthard Base Tunnel had been excavated. Only some 2.5 km is still missing until the main breakthrough between Sedrun and Faido takes place on October 15, 2010. The following report provides an overview on the stage reached by work.

The roughwork execution and the concreting operations for the inner lining also progressed parallel to the drive at all construction sites. At the end of 2009, 85 from 176 cross-passages had been furnished and roughly 9,427 m of inner vault concreted. Seen from the present viewpoint nothing stands in the way of the Gotthard Base Tunnel being opened in 2017 according to schedule (Fig. 1).

Gotthard North open Route

The open access route to the Gotthard Base Tunnel includes many engineering structures in addition to the rail line. No less than 6 underpassages of up to 75 m in length, 5 bridges with spans extending up to 21 m and a large number of passages and supporting walls have to be produced. Work is constantly progressing on various parts of the project.

The Gotthard Base Tunnel runs in a roughly 7.2 km long rock section in 2 single-track bores in the Erstfeld part-section, which were each driven by a tunnel boring machine of 9.58 m diameter. Driving in the 2 tubes was completed considerably earlier than scheduled between the Erstfeld portal and the Amsteg section boundary with the breakthrough accomplished in the eastern bore on June 16, 2009 and exactly 3 months later in the western one. After concluding the excavation in each case the tunnel boring machines had to be dismantled underground and retrieved through the excavated tunnel bores.

Driving Tunnels by Mining Means

The 2 tunnel boring machines attained outstanding rates of advance until the breakthroughs. In the eastern bore the JV Gotthard-Basistunnel Nord contract section 151 (AGN Los 151) arrived at an average rate of 18.27 m per working day. The objective of a minimal breakthrough error was also achieved with a technical breakthrough error of 14 mm measured crosswise to the tunnel axis and 5 mm regarding the height.

In the western bore an average rate of advance of 16.27 m per working day was achieved. With 56 m of cut and secured tunnel bore in 24 h the tunnel boring machine “Gabi II” accomplished a (world) record passage on July 19, 2009. The second breakthrough also took place with the utmost precision. The deviation crosswise to the tunnel axis only amounted to 9 mm in the straight and 7 mm regarding height.

The excavation was followed by installation of the invert with the waste water pipe being concreted into it. The 23 cross-passages were excavated parallel to these operations. In the interim the inner lining of 21 of them has been concluded. The 2 remaining cross-passages are required for logistical purposes in conjunction with excavating and securing the fork structures.

In both bores work on the foundations for the vault formwork, the kicker, is in progress. In the eastern bore 3,826 m accounting for more than 50 % had been concreted at the end of February 2010. 5,370 m (some 75 %) had been concreted in the western bore and made ready for the subsequent vault operations.

After the formwork units (comprising sealing car, reinforcement car, vault formwork and curing car) were transported from Amsteg to Erstfeld in January 2010, work on the vault started in the eastern bore in February 2010.

The innovative solution with verges consisting of prefabricated elements proved itself extremely well in Amsteg and was applied in Erstfeld instead of the in situ concrete construction method. Thanks to the elements precast in the concrete plant a higher degree of accuracy for laying the cable protection pipes in the verges can be attained.

Water Incidence

As was revealed last year the incidence of underground water in the Erstfeld part-section is considerably higher than forecast. The ingressing amounts of underground water have diminished substantially since the peak value of roughly 465 l/s was attained in July 2009. During the winter half year some 220 l/s flowed out of the tunnel. A new increase has to be reckoned with during spring/summer 2010. In order to be able to cope with the expected large amounts of water in summer 2010, the water treatment plant was extended by extra treatment channels. A capacity of 400 l/s is available with the possibility of handling an additional 100 l/s via an emergency treatment channel. The underground continuation of the Tunnel in the direction of Axen (Uri Berg Lang Axen (UBLA)) is laid down in the government’s AlpTransit sectoral plan.

As a prior investment and to avoid unfavourable constructional and rail operational general conditions for any subsequent task (“Uri Berg Lang Axen”), the underground fork structures are currently being excavated.

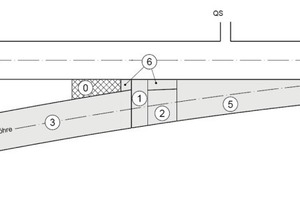

The roughly 400 m long chambers are trumpet-shaped and are driven via drill+blast. Initially the excavated area equals that of the single-track tunnels subsequently it is gradually increased over a length of 400 m and amounts to a maximum of some 200 m² given a 12 m track centre distance. At this point the thickness of the rock pillar between the single-track tunnel and the forking bores amounts to 3 m, the span width of the excavation some 22 m. Work on excavating the fork structure East began in spring 2009, while driving the fork on the western bore started in July 2009. Excavation operations are being undertaken in a number of stages (Fig. 3).

First of all the definitive rock pillar (0) must be secured. The access tunnel to the forking bore (1) is blasted and the service tunnel (2) subsequently required for the excavation operations driven. Now the drill+blast operations for the forking bore (3) can be commenced. Driving the 140 m (resp. 180 m in the western fork) long bore is divided up into excavating the crown and bench/invert. Then the fork is extended from the single-track tunnel (5). The roof and walls are also enlarged in stages. Finally the remaining sectors (6) are excavated. The working stage not shown here relates to excavating recesses in the points area.

As at the end of February 2010, 336 of 382 m for the enlargement East had been driven and secured. The enlargement operations were concluded by the end of April 2010. In the fork structure West so far 90 of 404 m has been excavated and supported. This work will be concluded in June 2010 (Fig. 4).

The 2 fork chambers are produced with a double shell with an excavation support constituting an anchorage system (friction anchors or mortar anchors) and a reinforced shotcrete shell, a seal and an in situ concrete inner shell. The thickness of the reinforced in situ concrete shell increases in keeping with the span width from 30 to a maximum of 45 cm. In the fork structure East vault operations are due to start in July 2010 and in November 2010 in the western one. The inner lining of the forking bores is limited to a monocoque shotcrete shell, however, the first 10 m correspond with the profile of the single-track tunnels and are provided with an in situ concrete inner vault.

Cut-and-Cover Tunnels

The first 600 m of the Gotthard Base Tunnel is produced by cut-and-cover. Operations began in April 2008. In their final state, the 2 cut-and-cover tunnel sections will be covered up to 14 m high with material obtained from the Tunnel. At the end of February 2010, 420 m of the eastern bore and 250 m of the western one had been completely concreted. Five different types of profile are needed to produce the 2 cut-and-cover tunnel sections.

The 2 tunnel bores run directly parallel to one another starting with the polygonal profile at the Erstfeld portal zone, which is visible in the final state of the Tunnel. Then the 2 bores run separately and the centre distance between the 2 tunnel bores increases from some 8 to 13 m towards the south. Inside the tunnel bores, the cross-section changes from a polygon to a horse-shoe shape. In the transition section from the cut-and-cover to the trenchless tunnel, the cantilever plate East is to be produced by summer 2010 providing the prior conditions for interconnecting the 2 tunnel profiles. The preparations for the western bore connection will be undertaken in winter 2011 (Fig. 5).

Amsteg Part-Section

In the course of 2009 the inner vault for the 2 bores was completed. To round things off the vault in the starting pipe section, assembly chamber and feeder point was installed in the eastern bore whilst the verge was produced in the western one. In the second half of 2009 the concreting operations for the cross-passage closing walls were completed and the cross-passages, fitted with doors as closures to the 2 tunnel bores. The cross-passages were provided with ventilation systems and raised floors. These floors consist of a sub-structure made of stainless steel, a lattice grate made of glass fibre reinforced plastic as well as fibre-reinforced, unfortified floor slabs.

Acceptance

The roughwork of the approx. 11 km long tunnel bores between Amsteg and Sedrun was finished according to schedule and is ready for installing the rail technology. On December 9, 2009 the 2 tunnel bores to the south of the assembly chambers up to the section boundary of the Sedrun part-section as well as the cable tunnel up to the Amsteg power station were approved. Through acceptance the structure – and in turn usage and danger – passed over into the responsibility of the client. Since January 15, 2010 the single-track tunnels East and West as well as the cross-sections have become the responsibility of the rail technology contractor.

Work is still progressing in the access tunnel and at the Amsteg bottom point. Extensive concreting operations are required particularly at the intersection area of the construction tunnel with the 2 single-track tunnels and at the feeder point. These are to be concluded by the end of 2011.

Sedrun Part-Section

Following extensive fault zones the southern drives reached the geologically favourable Paradies gneiss formation in early summer 2009. The outcome was average rates of advance amounting to 4 m/d given maximum rates of up to 7 m/d. On October 20, the drive reached tunnel kilometre 226.308 in the western bore South and thus the originally contractually agreed section boundary (incl. the 1 km option). In 2008, the ATG decided to relocate the section boundary towards Faido in order to adhere to deadlines.

The relocation of the Sedrun section boundary in the direction of Faido resulted in the accumulation of a further 750,000 t of spoil so that the material management concept had to be adjusted as the capacity of the existing dumps (Val Bugnei, Val Bugnei East) had been exhausted. During the first half of 2009, the installations for the Claus Surrein dump were set up. These include the belt conveyor system (conveyor over the Cavorgia bridge, distributor belts in the dumping area, distributor stations and transfer towers). It was possible to start dumping the spoil on October 1, 2009 according to schedule. Up until the end of March 2010, 143,000 t of spoil and mud was stored (Fig. 6).

In October 2009 a collapse occurred in the eastern bore at km 126.252.2. In the course of the mucking/securing measures the eastern roof and wall sector became increasingly waterlogged. Waterlogging of the kakiritic rock led to a gradual channel formation, which could no longer be prevented by placing shotcrete. The cave-in took place upwards as well as to the rear. Underground water apparently found its way from the surrounding rock to the otherwise relatively impermeable kakiritic sector through loosening (Fig. 7).

Inner Furnishing

Inner furnishing also made enormous progress in the Sedrun part-section. Following the successful technical test from km 120.200/222.200 to the section boundary North the 2 tunnel bores to the north of the multi function station (MFS) were handed over to the ATG according to schedule in October with the foreseen cost framework being adhered to. On January 15, 2010, this section was subsequently passed on to Transtec for the installation of the rail technology.

Faido Part-Section

Both tunnel boring machines were able to penetrate the Piora Basin without any difficulty (tunnel 4/2009, Successful Penetration of the Piora Basin in the Faido Part-Section). The drive in the Medelser granites that followed placed high demands on the machines with respect to wear on the cutting tools and cutterhead. The cutterhead had to be inspected every 1,000 m. There were not many surprises however in terms of construction technology. Slight seismic disturbances were occasionally registered. The initial water incidence amounted to 20 l/sec in certain sections, averaging a total of some 45 l/sec. The outcome was average rates of advance of 280 to 540 m/month. The Medelser granite intrusion zone was however, considerably longer than the forecast 2 km – and amounted to 4.5 km.

On March 2, 2010, the TBM East reached the Tenelin zone and then the Gotthard Massif folded gneisses. At present the excavation is located in the Borel zone, which so far had been penetrated unproblematically. The main breakthrough in the Sedrun section is scheduled for October 15, 2010.

The drives for the 2 tunnel bores are located in the Santa Maria reservoir’s sphere of influence. This dam has been carefully monitored in technical terms now for an extensive period. All deformations measured up till now lie far below the threshold value so that it has not been necessary to resort to any of the planned precautionary measures.

In the night from March 3 to 4, 2010 a cave-in occurred in the follow-up western bore in front of the cutterhead, which required several weeks to be mastered. Interestingly enough the TBM East passed through this shallow, 20 to 30 cm thick kakirite zone without major problems. At times however a 2 to 3 m overbreak above the cutterhead prevented the eastern TBM excavation from being properly executed. As a result the crew in the western bore was aware of the situation and had resorted to arch supporting in plenty of time as a precaution. Nonetheless the cave-in occurred, which currently can be estimated to be in excess of 1,000 m³.

Inner Furnishing

The inner furnishing of the Faido MFS took place parallel to the driving operations. Work in all exhaust air shafts in the western exhaust air system was concluded at the beginning of November, subsequently work started on furnishing the eastern exhaust air system. At present concreting is progressing mostly at a number of working points in order to ensure that the ambitious scheduling programme is adhered to.

Bodio Part-Section

The roughwork has been concluded, all the cross-passages have been equipped. After removing the rails for the tunnel railway, cleaning the tunnel and the successful technical test on December 17, 2009 the JV was able to hand over the western bore roughwork to the ATG. As a result the rail technical equipping of the Bodio western bore for the subsequent test stretch can thus begin as scheduled. Even although the individual activities may appear insignificant compared to the driving operations, the following figures document the major outlay that was required prior to the technical test in the more than 15 km long tunnel section. Thus for example a total of 63 km of pipelines had to be rinsed, cleaned and inspected by means of a camera robot for the drainage system. An area of 415,000 m² accounted for cleaning the inner vault and the surfaces of verge and base. The technical test revealed that a high quality of execution has also been attained in Bodio. Redevelopment work on the drainage system owing to damage or faulty execution was restricted to sections amounting to only a few hundred metres. This corresponds to less than 1 % of all pipeline systems. Only 13 of the 1,300 block joints for the inner vault had to be retrofitted in accordance with the guarantee, corresponding to a share of roughly 1 ‰ (Fig. 8).

At present the eastern bore is still being used for supplying the drives in the Faido section and removing the spoil by track. As a consequence the verges cannot yet be installed – this is intended to take place in the 2nd half year 2012. Subsequently the preparations for the technical test will begin there too.

Gotthard South (Biasca) Part-Section

Initial operations for the rail technological equipping of the Gotthard Base Tunnel started in May 2009. The first clod of earth was turned for the SBB operational control centre on November 28, 2009. The project has been named “Periscopio” on account of its futuristic architectural form. The new operational control centre or “Centrale d’esercizio di Pollegio” (CEP) is close to the Gotthard South InfoCenter. Rail traffic on the Gotthard axis between Chiasso and Arth-Goldau as well as between Bellinzona-Luino and Bellinzona-Locarno will be controlled from the operational control centre.