Efficient Use of Forepoling Technology at the Arlinger Tunnel

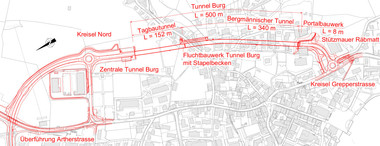

The 1.35 km long Arlinger Tunnel is part of the first construction phase of the “Westtangente Pforzheim”, the connecting axis of the German federal roads 294 and 463 from the Black Forest to the motorway 8. After the completion of the Westtangente Pforzheim, the Arlinger Tunnel will contribute to a significant traffic relief of the city centre of Pforzheim.

The two-lane bi-directional tunnel with a cross-section of approximately 90 m², two breakdown bays, an operations centre, the rescue tunnel with a length of 1.1 km as well as four cross-passages were excavated for the most part using conventional tunnelling methods. The excavation work began in 2019 and was carried out using both drill and blast and excavator driving.

Pipe Umbrella with Squeezed Connection

Due to the highly variable ground conditions – clays, marl and limestone, shell limestone as well as karst cavities – the “AT – 139 Pipe Umbrella System” was used as a pre-support measure. For the fully mechanised installation, the two booms of the Epiroc “Boomer E2C” jumbo were equipped with the “AT – Pipe Umbrella Automation Unit”. For this, the squeezed connection of DSI Underground was used, which is characterised by the following main advantages:

Increased working safety

Improved load capacity

Optimised quality and utilisation

A squeezed connection consists of a prefabricated reduced male pipe end, which is force-fitted with its female counter piece using a hydraulic clamping cylinder.

In contrast to standard threaded connections, squeezed connections do not exhibit any significant weakening of the load-bearing capacity in the joint area. In the course of installing the approximately 10 km of pipe umbrella tubes, it also became clear that the use of the squeezed system made a significant contribution to the timely completion of the tunnelling work compared to conventional screw threads. Thanks to the fully mechanised installation, a new milestone was also set in terms of work safety in tunnelling.

SN anchors type SN20-180 and self-drilling bolts “DSI Hollow Bar System” type R32-250 were used for excavation support, and tubular spiles 38 x 4 mm and 42.5 x 3 mm were used for pre- support. The breakthrough took place in December 2020; the tunnelling work was completed successfully and on schedule.