Sustainable Exploitation of Tunnel Excavation Material

The construction industry accounts for roughly a third of the greenhouse effect, requires about 40 % of the global energy supply and produces a volume of waste exceeding 50 %. Ensuring that tunnel excavation material is utilized as completely as possible in this connection represents an important contribution to forming a future-oriented economic system by increasing efficiency and effectiveness [1].

1 Introduction

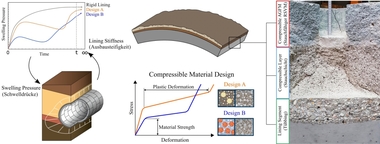

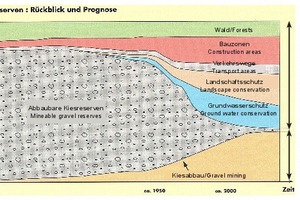

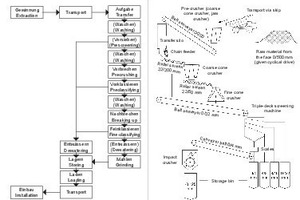

Unimpeded access to deposits of sand, gravel and industrial minerals will become increasingly more difficult in future on account of manifold surface utilization and more restrictive environmental considerations (Fig. 1). The excavated material accruing especially during tunnelling projects represents a considerable flow of waste; at the same time, frequently businesses are established in the direct proximity of tunnel projects that produce mineral raw materials. Seen in lithographic terms these raw materials correspond with the material excavated during the tunnel drive....

![Example of a longitudinal section with application classes (Phase A) [2]](https://www.tunnel-online.info/imgs/tok_9545a9c3f3fe3b70a57667c9bab65174/w300_h200_x397_y280_100848134_4fef03f726.jpg)

![Flow chart to characterize and establish the use of excavated material [4]](https://www.tunnel-online.info/imgs/tok_81d26b1ca821572998b40952d51640d8/w300_h200_x208_y297_100848137_ee738069a3.jpg)

![General conditions for utilizing tunnel excavation material [3]](https://www.tunnel-online.info/imgs/tok_0e74099ceed52618c453854693f294e5/w300_h200_x251_y177_100848155_f273b4aecd.jpg)

![Design of a prototype for real-time analysis of tunnel excavation material for TBM drives [6]](https://www.tunnel-online.info/imgs/tok_bb379fdd20170f0f1f1fbea244851413/w300_h200_x297_y161_100848188_b4247304be.jpg)

![Prototype for real-time measurement of grain size distribution, water content and chemical analysis of tunnel excavation material with connected data bank and sorting unit [6]](https://www.tunnel-online.info/imgs/tok_238d36b16970881726848b7585182728/w300_h200_x400_y209_100848141_c6dfd9b2e5.jpg)

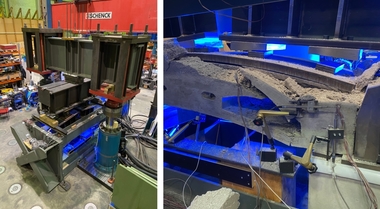

![Photo of the prototype at the Herrenknecht AG [5], [6]](https://www.tunnel-online.info/imgs/tok_7dc3e7fba6559a7076064827fb1f4c60/w300_h200_x397_y265_100848175_941b136d90.jpg)

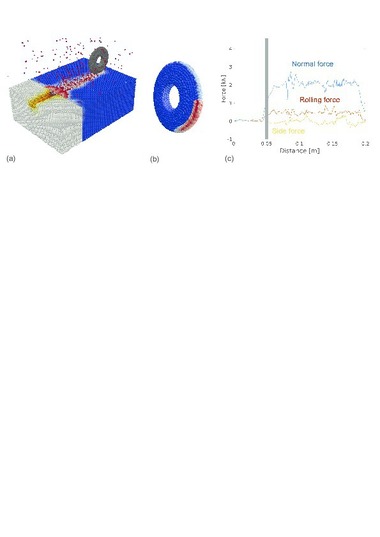

![Lab tests to measure disc forces on the linear test stand at CSM, Colorado, USA [7]](https://www.tunnel-online.info/imgs/tok_35b6a905edb2b1c5fc7d0ba9abdd114f/w300_h200_x400_y300_100848163_b7effbcffe.jpg)

![Disc force measurement results from three selected disc locations superimposed with the appropriate face image [11]](https://www.tunnel-online.info/imgs/tok_0d06c73489bb586092df543a54e2d5f2/w300_h153_x188_y76_100848156_e758694b5d.jpg)

![Estimation of the required amount of tunnel excavation material in proximity to the construction site [13]](https://www.tunnel-online.info/imgs/tok_5b432b0c12142af725e7a6f3d9112934/w300_h200_x251_y234_100848181_a50acbbbda.jpg)