Determining Abrasiveness of coarse-grained soft Ground

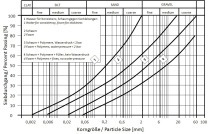

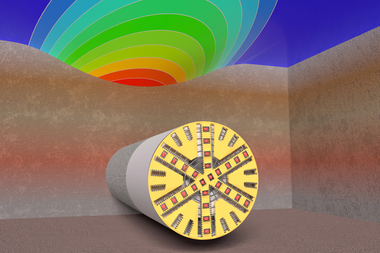

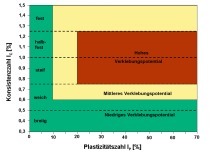

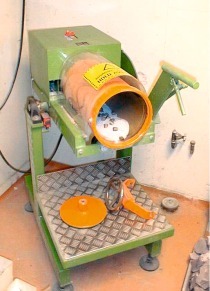

Defined in accordance with clients, contractors and test centres, this set of guidelines provides recommendations for describing soft ground (coarse-grained soils and gravel mixtures with a maximum grain size of 31.5 mm) with regard to its abrasiveness, in particular for establishing this in a uniform manner. In this way, the determining factors of influence can be simultaneously assessed in an index test and the test results compared with each other by means of a standard procedure (for example by applying the Vienna TU abrasimeter). Other in some cases standardized methods or those to be found in reference sources are also mentioned.

The guidelines are mainly aimed at clients and geotechnical planners, as the prerequisite is created by applying this particular test technique to provide reproducible comparative values for the abrasion of the investigated soils – also for tunnelling – during the ground development phase. The abrasiveness values can then also be linked to the wear (for instance experienced by the TBM) occurring during the execution of construction as well as with other on-site values. The appendices contain details on the Vienna TU abrasimeter, examples of test reports and presentations of results for abrasiveness as well as proposals for taking abrasiveness investigations into account at the tendering stage.

Guidelines of the Austrian Society for Construction Technology (ÖBV), October 2013

32 pp., DIN A4 with 20 Ill. /Tables and 35 Sources

17.50 euros

G.B.