62nd Geomechanics Colloquium in Salzburg

Once again Salzburg was the venue for the Austrian Society for Geotechnics’ Geomechanics Colloquium on October 10 and 11, 2013 involving numerous participants with many also from abroad. It is still Austria’s biggest annual event on this sector. The main aspects on this occasion were:

Power Water Conduits,

Special Measures in soft Ground,

International large Projects and

The Shaft as a Challenge.

All topics are of actual relevance as the construction of power plants, underground urban infrastructure and Base Tunnels as well as the sinking of extremely deep shafts reveals.

Prior to the Colloquium, 2 well-attended English-language workshops were held on October 9, 2013:

Characterization of Fault Zones and

Failure Predictions in Geotechnics

They resulted in interesting discussions unfolding.

Power Water Conduits

Long-term Behaviour of Power Water Conduits

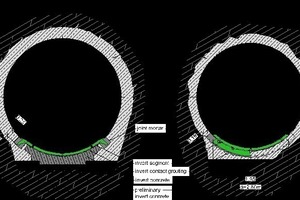

Power water conduits for Alpine hydro power stations are devised for a long service life so that no extensive repair measures are needed providing they are regularly checked and maintained. They must be permanently stable and sufficiently tight so that no parts from the lining or the rock enter the power water. During ongoing operation, repairs are not possible. Lining systems with circular cross-sectional forms (Fig. 1) with surfaces that are as smooth as possible (inner and outer ring with sealing and separating layers for subsequent injections) and making use of rock inter-action are customary. The focus was turned on damage images affecting the linings of power water conduits with extensive compilation of the causes and renovation measures as well as a number of examples such as the Lake Lünner pressure tunnel (1954-58) and Vermunt pressure tunnel (1925/30) with repair of the damage in the floor area in 1991/92 and 2003 partially using prefabricated parts.

Headrace and Tailrace Tunnels for the Beles Hydro Power Plant in Ethiopia

The Beles hydro power plant (2008 to 2010; 500 million euros) with 460 MW output (1,720 GWh/a) possesses a 11.9 km long headrace and a vertical armoured pressure shaft (270 m; 6.5 m inner diameter) as well as a cavern power house with adjoining 7.2 km long tailrace. The construction of the 2 tunnels with a double-shield TBM (8.1 m cutterhead diameter) with an inner diameter of 7.2 m was examined in conjunction with adapting the engineering equipment and requirements on the lining (segments, sealing, injections) given the varying geological and hydrogeological conditions.

New Construction of the Penstock for the Kaunertal Power Plant – Ground Exploration and Grouting Concept

Following ground exploration for the Kaunertal power plant in Tyrol a 1,430 m long penstock with a 5.54 m excavated diameter and 4.30 m inner diameter with segmental lining was produced. In this connection, details on the ground investigation and the grouting concept were provided. For example, systematic percussion drilling and seismic investigations as well as core drilling were provided. For activating the rock’s bearing capacity, grouting (GIN methods) as well as contact and compaction injections were undertaken – with the grouting results evaluated on a daily basis and the outcome of the injections constantly appraised.

Special Measures in soft Ground

Structural Protection for urban Tunnelling taking the Example of the Rome Metro

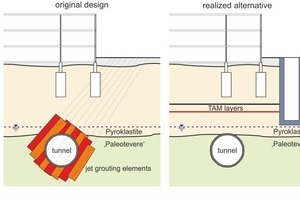

Soilfrac injections (Fig. 2) were applied advantageously for the B1 Metro in Rome instead of traditional soil improvement measures (jet grouting) to prevent structural damage in tunnel driven in downtown areas. One advantage was the fact that less space was needed as the number of shafts was reduced; furthermore a relatively smaller amount of structural material was required. The deformations on the structures were considerably less than the permissible values in spite of the major tunnel diameters (6.8 and 9.8 m), the tricky soil conditions and the shallow overburden. In addition, controlled horizontal drilling was applied to a large extent for the first time for the Rome Metro and structures raised by means of pile foundations (please see Fig. 2).

International large Projects

Design and Construction of the Second Avenue Subway in New York

The construction of the 13.7 km long Second Avenue Subway with 16 stops on the east side of Manhattan at a cost of an estimated 19 billion USD (13 billion euros) is one of the biggest building projects in the USA. According to the current draft plan for extending the route, 10 stations are to be produced via cut-and-cover and 6 by excavating caverns: the external diameter of the tunnels being driven amounts to 6.6 m and the span width of the caverns equals 12 to 21 m. The route leads through solid rock and soft ground with numerous rock-soil transition points. The report provided details of the planning, design and construction of the first phase in the very densely populated urban surroundings of Manhattan. The report also contained information on the geological conditions, ground investigations, the design concept entailing the empirical Q method and the discontinuity analysis.

The new Semmering Base Tunnel Project

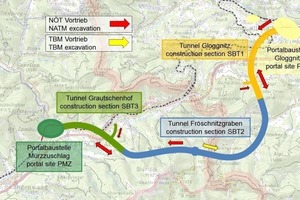

For 8 years a team of the ÖBB-Infrastructure AG has been intensively engaged in this project for the building of a roughly 27 km long flat railway tunnel with two single-track bores connected at 500 m gaps by cross-passages and an emergency stop at the centre of the tunnel with a 420 m high ventilation shaft. The tunnel is to be driven from both portals (Gloggnitz and Münzzuschlag) and 3 intermediate points of attack (Göstritz, Fröschnitzgraben and Grautschenhof). It will be excavated both cyclically (NATM) as well as continuously (with TBM) (Fig. 3) and opened in 2024. Details were provided on the individual contract sections and ever new challenges for project applicants, planners and contractors.

The Shaft as a Challenge

Modern and innovative Shaft Construction Technology taking current Projects into Consideration

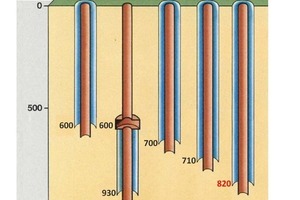

The sinking and lining of shafts for winning raw materials and for engineering structures represents a major challenge for clients, project engineers and contractors. In this connection, modern and innovative shaft building technology was explained taking current projects into account such as freeze hole drilling down to a depth of 820 m to reach potash and rock salt deposits (Fig. 4) and partial freezing of a cavern produced by mining means down a shaft at a depth of 600 m to reach a freezing depth of 930 m in the United Kingdom as well as ultra-deep shafts with a final depth in excess of 2,000 m applying drill+blast. In this way, the latest in the way of modern shaft building technology was dealt with in conjunction with freeze shaft and drilling technology as well as in the field of conventional shaft construction. Apart from the technical challenges specific construction management and logistics tasks were also dealt with.

Workshops

Characterization of Fault Zones

Fault Management in deep-lying Tunnels

After failure predictions in geotechnics, reports on the characterization of fault zones followed, with particular reference to the fault zone management for deep-lying tunnels introduced in conjunction with the construction of the Brenner Base Tunnel (BBT) [Burger, BBT SE Innsbruck; Marcher und Saurer, ILF, Innsbruck; Soldo, GEODATA, Milan/I]. The deeper the tunnel, the greater are the outlay and the costs for the exploration measures so that risks can be reduced. Details on other tunnel projects were provided, for example a fault zone management image as well as provisions for geological and tectonic fault zone presentation and an overview of possible forms of danger (instability, hindering the mechanised drive, cave-ins, rockfalls and deformations at the surface) as well as corresponding measures during drill+blast and mechanised drives.

Failure Predictions in Geotechnics

Geotechnical Observations during the Niagara Tunnel Project

Following details relating to the characterization of fault zones, the focus was turned on predictions in geotechnics and in particular on geotechnical observations during the Niagara Tunnel project (NTP) [Perras und Diederichs, University of Kingston/CAN; Wannemacher, Marti, Moosseedorf/CH]. Problems resulted there at the boundary layer in conjunction with the sinking of a shaft at a depth of 140 m owing to the rock structure given a plastic flow of up to 1.9 m. A numerical simulation was executed to reach clarification, which was also successfully applied in advance for planning a shaft in the same layer for storing radioactive waste in Canada.

Further details relating to the Colloquium are to be found in Vol. 6/2013, pp. 385-617 of the journal Geomechanik und Tunnelbau. Special English-language proceedings for the 2 workshops are available from the ÖGG (72/45 pp. with numerous Ill. /Tables and Sources). – The 63rd Geomechanics Colloquium will be held on October 9 and 10, 2014 again in Salzburg and the Austrian ITA Tunnel Day, held every 2 years, will take place the previous day.⇥G.B.