Construction of the Transport Tunnel for the Woodsmith Mine Project

The world´s largest known resource of polyhalite minerals is located in northern England in the county of North Yorkshire, close to Whitby. To unearth the mineral, which is used in the production of fertiliser, a 37 km long tunnel for the transport system is under construction from the east coast to the Woodsmith polyhalite mine. Sirius Minerals Plc (aquired by Anglo American in March 2020) awarded the design-and-build contract of the first 13 km tunnel section to Strabag SE in March 2018. In June 2019 the order was extended for another 24 km of mechanized tunnelling and the construction of the 37 km long underground conveyor belt system.

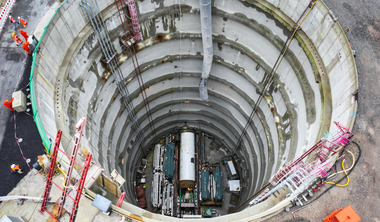

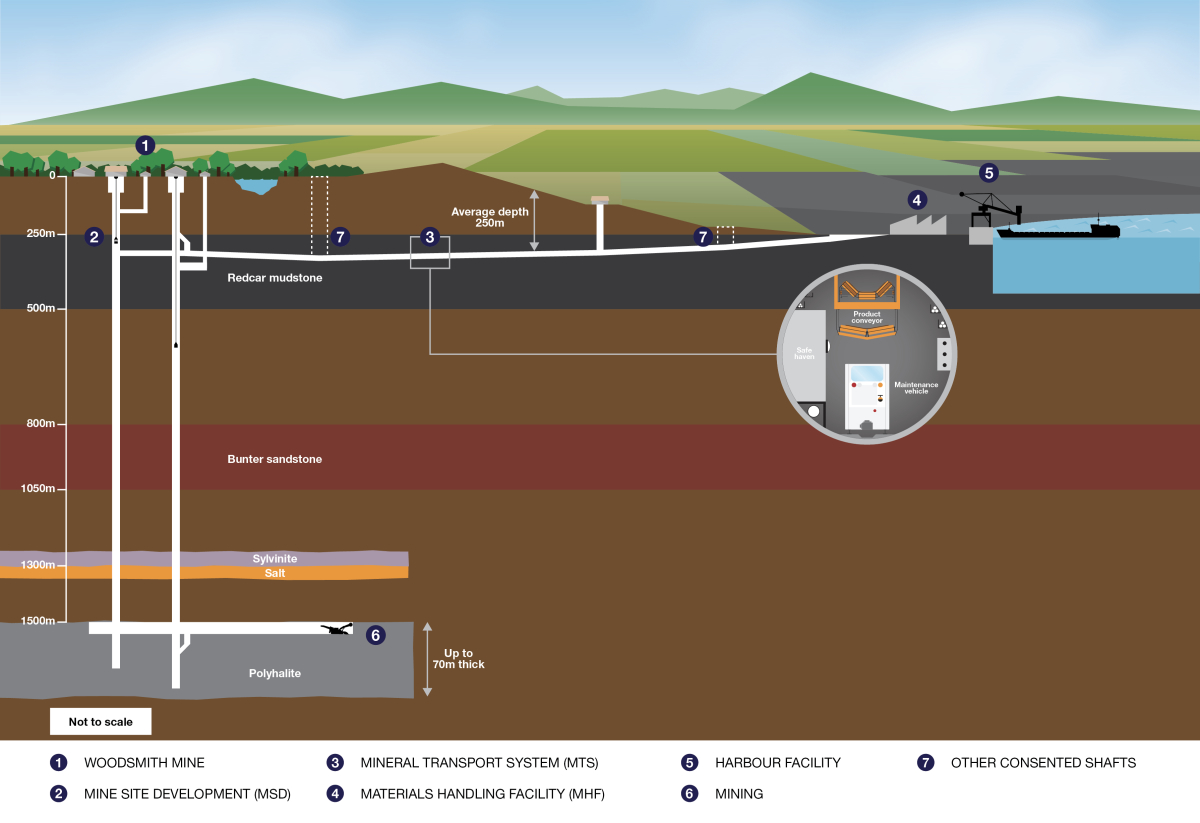

The polyhalite deposits are located about 1500 m deep under the North York Moors National Park, and due to the neighbourhood to this nature preserve the transportation of the mineral will be done underground in a tunnel. Once the shafts are completed, the polyhalite will be excavated and lifted upwards via a 1550 m deep shaft to an underground cavern. From there it will be moved through the tunnel via the Mineral Transport System (MTS) to the harbour in Wilton (Fig. 1).

1 Overview of the tunnel alignment for the Woodsmith Mine project

1 Overview of the tunnel alignment for the Woodsmith Mine project

Credit/Quelle: Sirius Minerals Plc

A 6 m diameter single-shield Herrenknecht rock TBM started the first 13 km from the portal in Wilton (Teesside, Northwest of the mine) in June 2019, sloping 3.5 to 0.9% downwards to the intermediate shaft with a first long cavern at Lockwood Beck. A second TBM will be launched in 2022 starting from the transportation shaft of the Woodsmith mine to excavate the 24 km to the intermediate shaft.

The construction of the tunnel began with a 300 m long open cut area into a 100 m long shotcrete lined (SCL) tunnel. Originally, the SCL tunnel was supposed to be 800 m long, but the distance could be shortened since the rock conditions turned out to be slightly better than anticipated rock conditions. The SCL tunnel was completed in April 2019. In June 2019 the TBM reached the rock face to begin full face excavation in the Redcar Mudstone, the main geology. Approximately 13.5 km of the tunnel had been excavated by end of March 2021.

Geology and Monitoring

Geological data, geophysical borehole surveys and seismic traverses, surface mapping as well as 12 boreholes along the tunnel alignment were available, also, data from historical and recent mining activities. In addition, fault sensors at the TBM, shape arrays and triaxial nodes to detect movements, probe drilling ahead of the TBM in certain areas, in-situ stress measurements as well as face scanning are used during tunnelling.

TBM and Segmental Lining

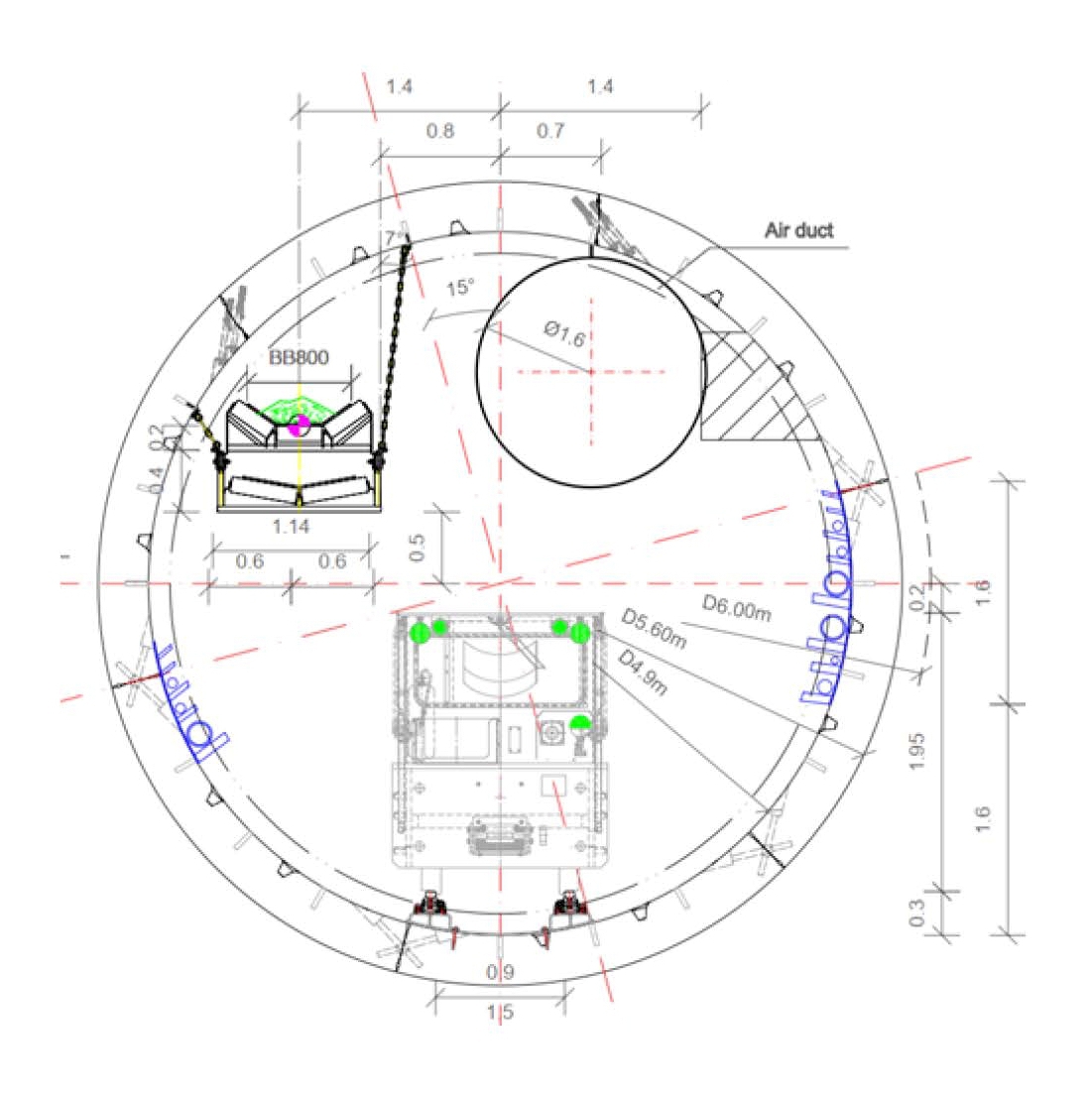

The 1775 t single-shield Herrenknecht rock TBM S-1175 works with an installed cutterhead power of 2100 kW (6 x 350 kW). The excavated diameter of the tunnel is 6.0 m, with an external lining diameter of 5.6 m and an internal lining diameter of 4.9 m. The lining is built with 5+1 segments per ring (Fig. 2).

2 Cross-section of the TBM tunnel under construction

2 Cross-section of the TBM tunnel under construction

Credit/Quelle: Strabag

The length of the segments is 1.5 m. The lining thickness is 35 cm, with a 20 cm wide annular gap. The lining is a high strength design with three main segment types. The strongest segment is designed to take the overburden pressure as well as the up to 29 bar hydrostatic pressure. These segments are reinforced with a steel cage up to 125 kg/m³ and are manufactured with a concrete grade C50/60.

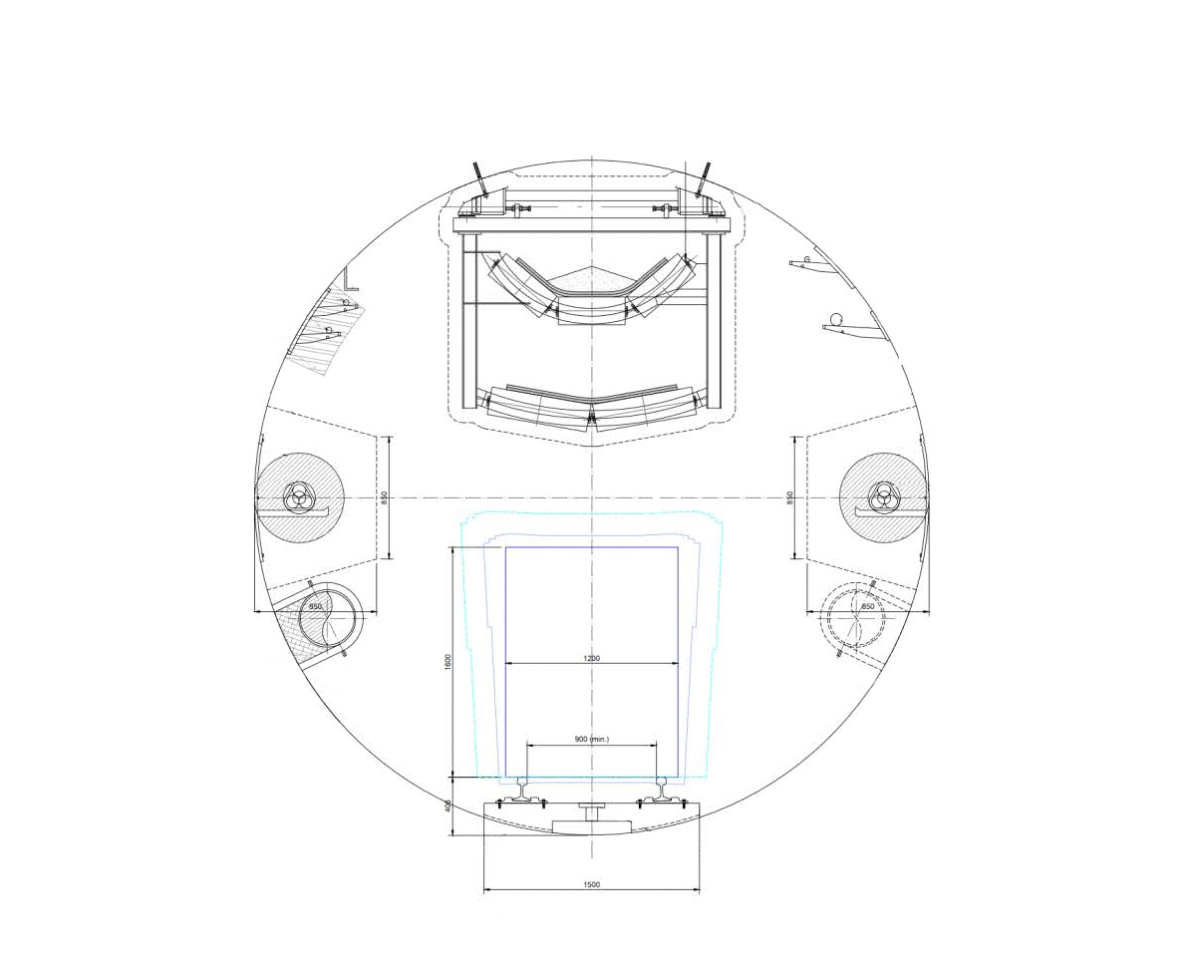

After completion of the tunnel, only small modifications of the single track construction railway system are needed to make it permanent for maintenance and services (Fig. 3). The permanent tunnel fit-out includes the Mineral Transport Conveyor belt system (MTS) divided into two systems with lengths of 24 km and 13 km.

3 Cross-section of the completed tunnel

3 Cross-section of the completed tunnel

Credit/Quelle: Strabag

TBM Performance

The TBM excavation started in June 2019, and due to the strict selection process of the TBM, the advance rate is very high. Strabag managed a good and consistent daily advance rate, with the best excavation day of 52.65 m in 24 h and the best month with 1012 m in October 2020. Due to this high performance, the project was 5 months ahead of the programme at the end of March 2021. Nevertheless, some downtime had to be managed caused by some probe drillings in the fault zones, technical stops for cable and conveyor belt extensions as well as clogging of the cutterhead.

This article is based on a presentation of Ernst Gschnitzer, Julian Wenger and Andy Raine of Strabag AG, UK Branch, who gave an overview of the construction advance at the virtual 69th Geomechanics Colloquium 2020.