Cutting Tool Advancements for long Tunnel Drives and Geologic Extremes

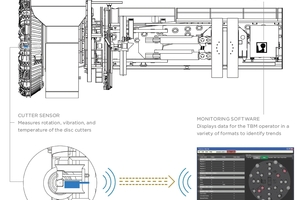

Extreme tunneling conditions call for the most robust TBM cutting tools possible—whether that includes hard and abrasive rock, long-distance tunnels of 15 km or more, or high water pressures. Extreme conditions can be defined as those conditions that result in poor advance rate, catastrophic disc cutter failure, or unacceptable wear life of a disc cutter. While disc cutters are widely considered a mature technology,

there is room for growth and development, spurred on by increasing numbers of projects in difficult ground.

At China’s Yin Han Ji Wei project for example, hard rock, combined with face collapses, damaged cutters and prompted engineers to design a more robust cutter ring to survive in the most severe conditions. It is not just hard rock prompting design changes: at New York, USA’s Delaware Aqueduct Repair, a Single Shield TBM is boring in rock with water pressures up to 20 bar. The 19-inch diameter disc cutters utilize a pressure compensation mechanism that has been bench-tested up to 34 bar in order to excavate under the high pressures. These are just a few of the developments currently being tested...