DESOI w.i.l.m.a. – Wireless Injection Logging Monitoring Assistent

Tradition and innovation, that does not have to be a contradiction, as the family-owned company Desoi from Hesse (Germany) shows. True to the spirit of Charles Darwin, that only those advance who move with the times and adapt as necessary, the specialist for injection technology has set itself the task of simplifying work on the construction site with modern means. With the Desoi w.i.l.m.a. recording and documentation device, the integration of mechanics and state-of-the-art electronics has enabled the leap into Industry 4.0.

With the use of the w.i.l.m.a. system, masonry injections during the refurbishment of Hamburg‘s underground line 3 could be carried out efficiently and successfully

With the use of the w.i.l.m.a. system, masonry injections during the refurbishment of Hamburg‘s underground line 3 could be carried out efficiently and successfully

Credit/Quelle: DESOI

The Idea

Traditionally, Desoi’s product range was very mechanically oriented, from packers, hoses and cylinders to mixing and pumping equipment and anchoring systems. Desoi w.i.l.m.a., on the other hand, is an electronic, digital solution. The incentive to take this direction came from the customer’s side. The priority of Desoi’s customer service is to listen and put into practice what the client needs. This gave rise to the idea of a data logger for injection works.

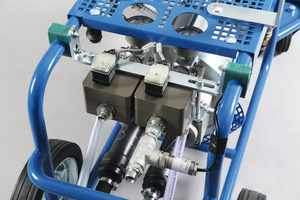

Recording and documentation system w.i.l.m.a.-PU for polyurethane and silicate resin

Recording and documentation system w.i.l.m.a.-PU for polyurethane and silicate resin

Credit/Quelle: DESOI

Since it is an owner-managed company, decisions can be made quickly. Another decisive factor was the determination of the management to evolve the company further. The fact that in a family business like Desoi the boss, at 80 years of age, still keeps up with the times and is even one step ahead of them is not something that can be taken for granted.

After some experience with predecessor models of the recorder, Desoi w.i.l.m.a. was brought onto the market by means of further development and constant improvement.

The Partner

Choosing the right partner is essential for the development of new products: eguana GmbH (www.eguana.at), based in Vienna, was founded in 2015 and offers solutions for digitalisation in special civil engineering and tunnel construction.

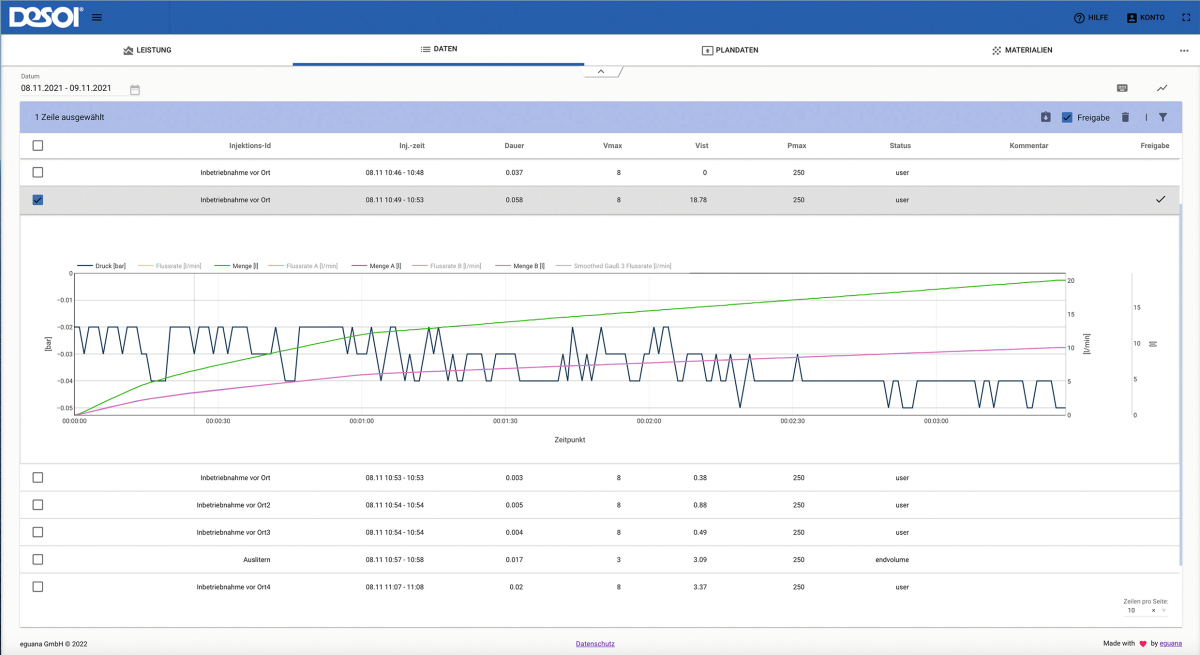

This partnership for digitalisation works well between the companies and, above all, between the people in charge. Reliability, trust and open communication enable the flexibility that customers want: The data from w.i.l.m.a. is automatically transmitted to eguana SCALES, a platform for the evaluation, analysis and graphic representation of construction sites.

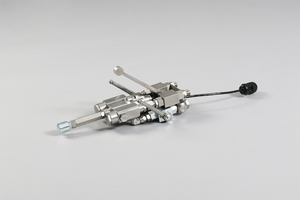

Desoi w.i.l.m.a. records the pressure, volume, time and any deviations of the injection processes

Desoi w.i.l.m.a. records the pressure, volume, time and any deviations of the injection processes

Credit/Quelle: DESOI

w.i.l.m.a. – Wireless Injection Logging Monitoring Assistent

w.i.l.m.a. is a high-tech system that records the data generated during or required for an injection. In the conventional procedure, data generated during an injection is collected and either documented on paper or transferred to a local computer. With w.i.l.m.a., however, the data flow no longer ends at the device, but is transmitted wirelessly to eguana SCALES. To protect the sensitive data related to the injection processes, tablet and base unit communicate via a secure WLAN connection.

All data is protected for the user with passwords and is processed and managed exclusively on servers in Germany. On the digital platform, they can be viewed, analysed, handed over to clients and also printed out by those involved in the project from anywhere. Alternatively, the data can be downloaded or transferred to clients‘ data processing.

Desoi w.i.l.m.a. records the pressure, volume, time and any deviations of the injection processes. To ensure that no inadmissible deviations occur during injection, limit values for the mixing ratio, pressure and volume can be defined in advance. If these values are exceeded, either a message is displayed on the tablet or alternatively the entire system is switched off.

w.i.l.m.a. ensures that planned consumption quantities and prescribed technical parameters are permanently monitored and adhered to, e.g. mixing ratio and injection pressure. The matching machine

technology is reliable, robust, field-tested and enables a high degree of execution safety. On request, the system can also be equipped and adapted to suit the project and application.

The following versions are available:

w.i.l.m.a.-AY for acrylate gel, 2-component, magnetic/inductive flow sensor, pressure sensor 0–250 bar and rinsing pump

w.i.l.m.a.-PU for polyurethane and silicate resin, 2-component, gearwheel sensors, pressure sensor 0–250 bar

w.i.l.m.a.-Z for cement, 1-component, magnetic/inductive flow sensor, pressure sensor 0–40 bar

The delivery of Desoi w.i.l.m.a. for all variants includes, in addition to the operating instructions, professional instruction on the construction site by an experienced application technician with subsequent application support. Of course, w.i.l.m.a. can also be ordered via the Desoi rental centre for the duration of the work.

w.i.l.m.a. is suitable, among other things, for the application areas of masonry injection, curtain injection, anchor bonding and ridge gap grouting. Customer feedback on the device is consistently positive; users are completely convinced by the simple application, the clear digital recordings and the fast processing.

Users are fully convinced by the simple application, the well-structured digital records and the fast processing with the w.i.l.m.a. system

Users are fully convinced by the simple application, the well-structured digital records and the fast processing with the w.i.l.m.a. system

Credit/Quelle: DESOI

Although the recording and documentation unit w.i.l.m.a. is already in use at various customers, different applications and adaptations continue to be requested. For example, a further development is planned in the near future that will make it possible to regulate the volume in relation to the injection pressure.

The section of underground line 3 in Hamburg‘s city centre is currently being renovated. Damaged and damp spots on ceilings and walls had to be permanently protected against moisture for the future

The section of underground line 3 in Hamburg‘s city centre is currently being renovated. Damaged and damp spots on ceilings and walls had to be permanently protected against moisture for the future

Credit/Quelle: DESOI

The Project: U3 Tunnel Renovation Hamburg

The route of underground line 3 in Hamburg‘s city centre is currently being renovated. A major challenge: the tunnel the U3 has been using for over 100 years had to be renovated and sealed in some places. Damaged and damp spots on ceilings and walls had to be permanently protected against moisture for the future.

For this purpose, sealing masonry injections with 2-component injection resin (PU) had to be carried out. This involved working in a heritage-protected structure – an additional constraint for those involved in the project.

A major challenge: the tunnel the U3 has been using for over 100 years had to be renovated and sealed in some places

A major challenge: the tunnel the U3 has been using for over 100 years had to be renovated and sealed in some places

Credit/Quelle: DESOI

The first injection tests on site had already been carried out by the contractor with a 1-component diaphragm pump. The material used had to be mixed before injection and injected within the specified processing time. In between, it was necessary to flush the machine. Exact adherence to the pressure and quantity parameters was only possible to a limited extent, and the client was unable to track the injections carried out.

It was therefore decided to use the Desoi w.i.l.m.a.-PU machine for further work. In summary, here are the most important advantages of w.i.l.m.a.-PU in the tunnel rehabilitation work:

Time saving, as the material was conveyed and mixed directly by the 2-component unit

exact adherence to the specified parameters

additional time saving, as the material could remain in the machine and no intermediate flushing was necessary

transparency for the client regarding the procedure for the individual injections

In this way, the masonry injections could be carried out efficiently and successfully.

DESOI w.i.l.m.a. Information Brochures

Here you can find information brochures about the recording and documentation system w.i.l.m.a. for injection and dosing processes. The information brochures for all available models are available as pdfs in German and English.