Face Support Pressure, Soil Conditioning and Material Transport in Hydro and EBP Shields

The support pressure of tunnel boring machines (TBM) determines the stability of the tunnel face during excavation. The calculation of the necessary support pressure in turn requires a fundamental understanding of the behaviour of the excavation process and the soil in the excavation chamber. In this article, experimental methods and tests for both earth-pressure and hydro shield machines as well as numerical models for the simulation of material transport and mixing processes in the pressure chamber are presented.

1 Soil Conditioning in Tunnelling with EPB Shields

The evaluation of the support medium inside the excavation chamber during advance with an EPB-shield in closed mode is only indirectly possible by interpreting machine data or by observing the muck on the conveyor belt. If the soil does not have the appropriate properties, the specific use of conditioning agents e.g. foam can temporarily create a support medium, suitable for EPB tunnelling. Therefore, rheometric experiments and the development of rheological material parameters for different soil types and conditioning agents were implemented from micro and meso to macro (real) scale with different test devices [1]. For real scale investigations, a ball measuring system (BMS) was developed and installed in the large-scale test device COSMA (Fig. 1, left).

1 | Test device COSMA with integrated BMS (left); force controlled penetration test prototype (right)

1 | Test device COSMA with integrated BMS (left); force controlled penetration test prototype (right)

Credit/Quelle: RUB

In the laboratory as well as at the construction site, the slump test [2] is an adequate and internationally used test method to investigate the workability of soil-foam mixtures. Since the slump test is not suitable for examining coarse-grained gravelly or purely cohesive soils, a new penetration test was developed to examine the workability of all kinds of soil mixtures and conditioning agents. In a first step, a force-controlled device was developed (Fig. 1, right) based on the method of the Kelly ball test in concrete technology and the fall cone test in soil mechanics. In further investigations, a path-regulated test device will be developed for evaluation of rheological parameters. Furthermore, a new conditioning agent will be developed to extend the application range to EPB shields in very coarse soils and rock.

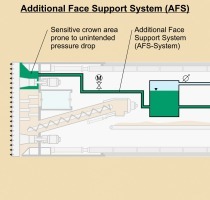

2 Local Transient Face Support within Hydro Shields

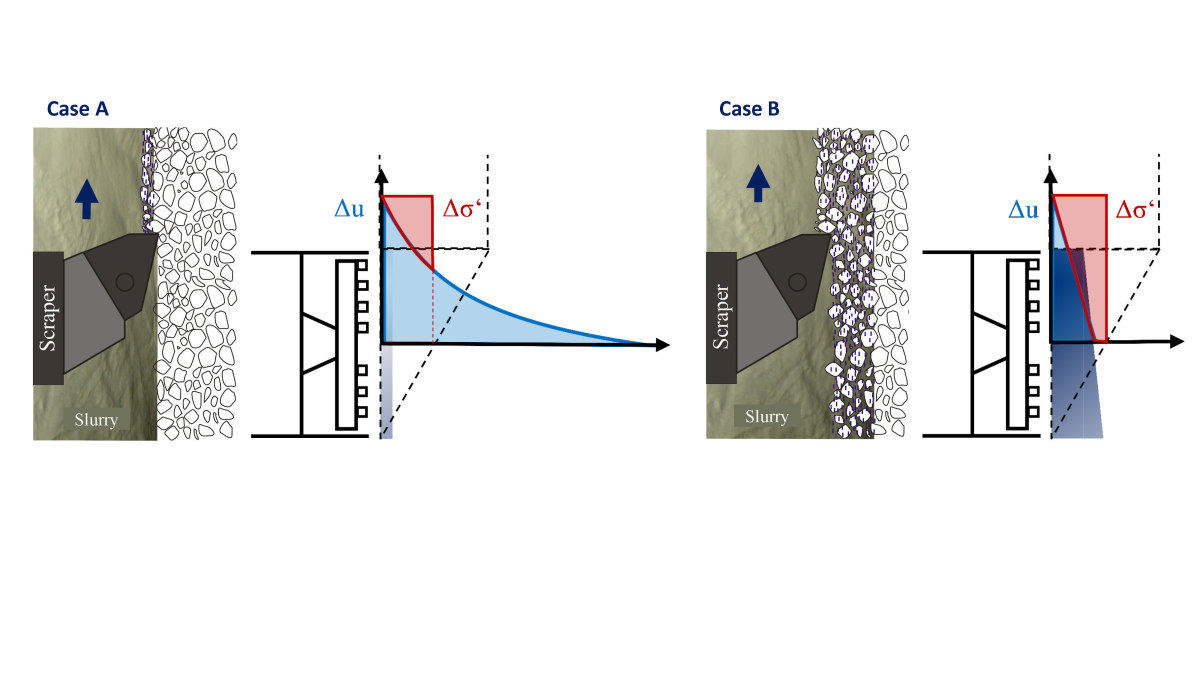

The project aims to describe the time-dependent processes at the fluid supported tunnel face during the transfer of the support pressure under simultaneous soil excavation. In the process, the tunnel face is stabilized by the support pressure of a bentonite suspension counterbalancing the earth pressure and groundwater pressure. During excavation, this zone of the support pressure transfer is periodically removed by the cutting tools, affecting the slurry penetration processes and resulting in a time-dependent pressure gradient in the area of tunnel face [3, 4].

Several parameters affect the transfer of the support pressure: suspension rheology, permeability of the non-cohesive soil, penetration rate of the shield machine, etc. Based on the ratio of the penetration depth of the cutting tools to the penetration depth of the suspension, two types of support scenarios can be distinguished.

Case A: The entire penetrated zone is completely removed by the cutting tools and restored behind the tool passing. Immediately after the tool passing, increased pore water pressures (∆u) result outside of the theoretical sliding wedge (Fig. 2, left).

2 | Local distribution of effective stress ∆σ‘ and pore water pressure ∆u at tunnel axis [3, 4]

2 | Local distribution of effective stress ∆σ‘ and pore water pressure ∆u at tunnel axis [3, 4]

Credit/Quelle: RUB

Case B: Only a part of the penetrated zone is removed and restored behind the passing tool. A penetrated zone with modified soil mechanical and hydro-mechanical properties remains behind the passage of the excavation tool, into which the bentonite suspension penetrates again (Fig. 2, right). These effects must be transferred into constitutive models for stability calculations of the tunnel face [3, 4].

3 Transport and Mixing Processes in the Pressure Chamber

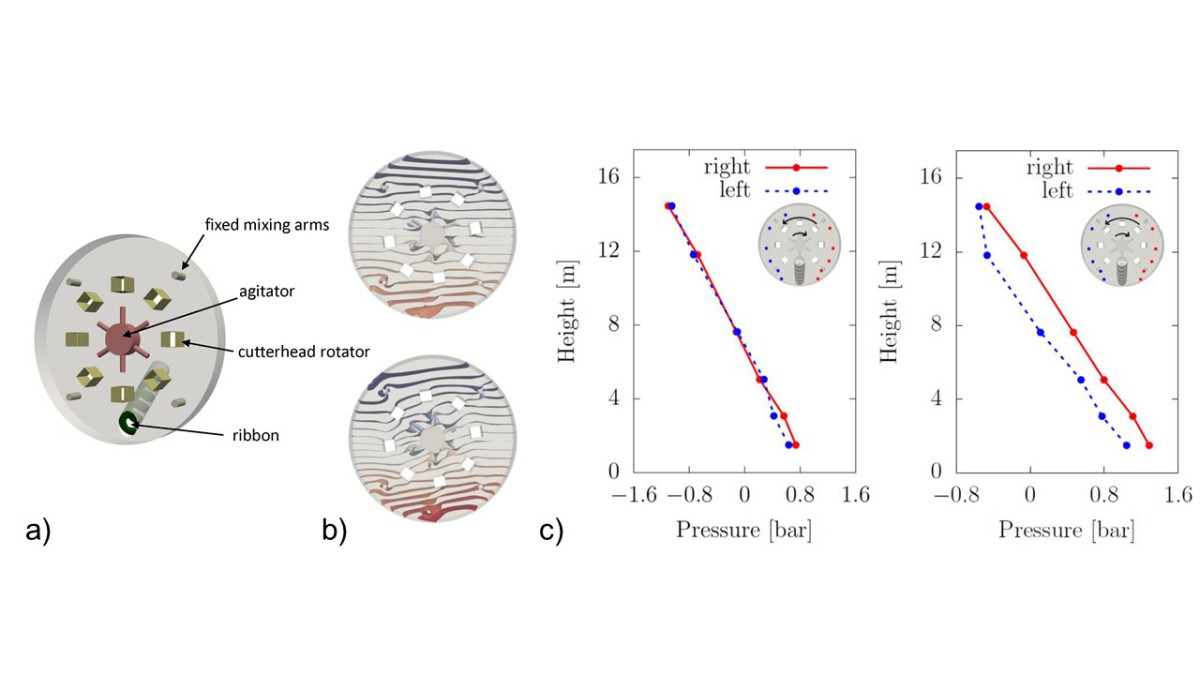

To gain insight into the influence of the machine design, operational parameters and the soil paste properties on the transient flow and pressure conditions in EPB shield machines, a computational model for the material transport in EPB machines has been developed. The numerical model contains all interactions of the soil paste penetrating through the rotating cutterhead with the mixing arms, agitators and the screw conveyor [5]. Essential characteristics, such as the left-right unbalanced pressure distribution depending on the foam injection ratio and pressure fluctuations in the chamber, are shown to be in agreement with practical observations and allow an assessment of face stability (Fig. 3). To facilitate the generation of computational models for different designs, the finite cell method is used in current extensions of the model to allow to directly incorporate complex geometries of the chamber and the cutterhead generated from CAD data [6].

3 | a) Computational model of a 17,5 m EPB pressure chamber equipped with a center agitator and fixed mixing arms, b) simulated pressure contours for incompressible (top) and compressible muck (bottom), c) Pressure profiles along the circumference of the bulkhead for incompressible (left) and compressible muck (right) [5]

3 | a) Computational model of a 17,5 m EPB pressure chamber equipped with a center agitator and fixed mixing arms, b) simulated pressure contours for incompressible (top) and compressible muck (bottom), c) Pressure profiles along the circumference of the bulkhead for incompressible (left) and compressible muck (right) [5]

Credit/Quelle: RUB

Collaborative Research Center “Interaction Modeling in Mechanized Tunneling” (SFB 837)

The German Research Foundation (DFG) established the Collaborative Research Center “Interaction Modeling in Mechanized Tunneling” (SFB 837) at Ruhr University Bochum in 2010. The SFB 837 is currently the largest research group conducting fundamental research in tunnelling-related topics worldwide. The research goals are concerned with various relevant planning and construction aspects of the many components of the mechanized tunnelling process.

Selected results of research performed in the SFB 837 with a focus on the transfer potential to tunnelling engineering are be presented in a series of short articles in tunnel.

Acknowledgement

This research has received funding from the German Research Foundation (DFG) in the framework of the Collaborative Research Center SFB 837 “Interaction Modeling in Mechanised Tunnelling” (project number 77309832). This support is gratefully acknowledged.

References

[1] Galli, M. (2016): Rheological Characterisation of Earth-Pressure-Balance (EPB) Support Medium composed of non-cohesive Soils and Foam. Ph.D. Thesis, Ruhr-Universität Bochum, 2016.

[2] EN 12350-2: Testing fresh concrete - Part 2: Slump-test; German version. DIN Deutsches Institut für Normung e. V., Beuth Verlag GmbH, Berlin 2009.

[3] Zizka, Z. (2019): Stability of slurry supported tunnel face considering the transient support mechanism during excavation in

non-cohesive soil. Ph.D. Thesis, Ruhr-Universität Bochum. DOI: 10.13154/294-6514

[4] Kuepferle, J.; Zizka, Z.; Schoesser, B.; Röttger, A.; Alber, M.; Thewes, M.; Theisen, W. (2018) Influence of the slurry-stabilized tunnel face on shield TBM tool wear regarding the soil mechanical changes – Experimental evidence of changes in the tribological system. Tunnelling and Underground Space Technology, Vol. 74, pp 206-216. DOI: 10.1016/j.tust.2018.01.011

[5] Dang, T. S.; Meschke G. (2020): Influence of muck properties and chamber design on pressure distribution in EPB pressure chambers – Insights from computational flow simulations. Tunnelling and Underground Space Technology, Vol. 99, pp. 103333. DOI: 10.1016/j.tust.2020.103333

[6] Saberi, S.; Vogel A.; Meschke G. (2020) Parallel finite cell method with adaptive geometric multigrid. Euro-Par 2020. Springer. DOI: 10.1007/978-3-030-57675-2_36