Ground Freezing Measures for the Extension of the U in Frankfurt am Main

Ground freezing is a state-of-the-art construction method that significantly reduces the impact on the subsoil and the surrounding areas. The method is used, among other things, when drilling from the surface is impossible due to dense urban development or geographical constraints. This was precisely the case with the extension of underground line 5 into the “Europaviertel” district in Frankfurt am Main (Germany): In the highly sensitive, densely built-up inner city location, the tunnel construction work had to be carried out without damaging the existing buildings and without obstructing the above-ground traffic.

Ground freezing is a flexible procedure that is mainly used for complex measures and for construction works involving existing structures. Here, the ground is solidified and made impermeable to water by artificially freezing the soil water. The resulting frost body gives the subsoil a very high degree of stability and protects it from water ingress until these functions can be taken over by the later structure. After the end of the construction work, thawing occurs naturally. Apart from the injection lances, ground freezing leaves no artificial additives in the subsoil. The high requirements for safe inner-city underground tunnel construction are met by means of targeted freezing of critical construction areas.

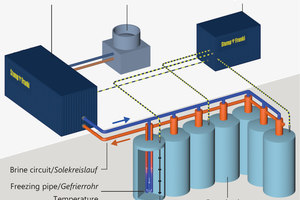

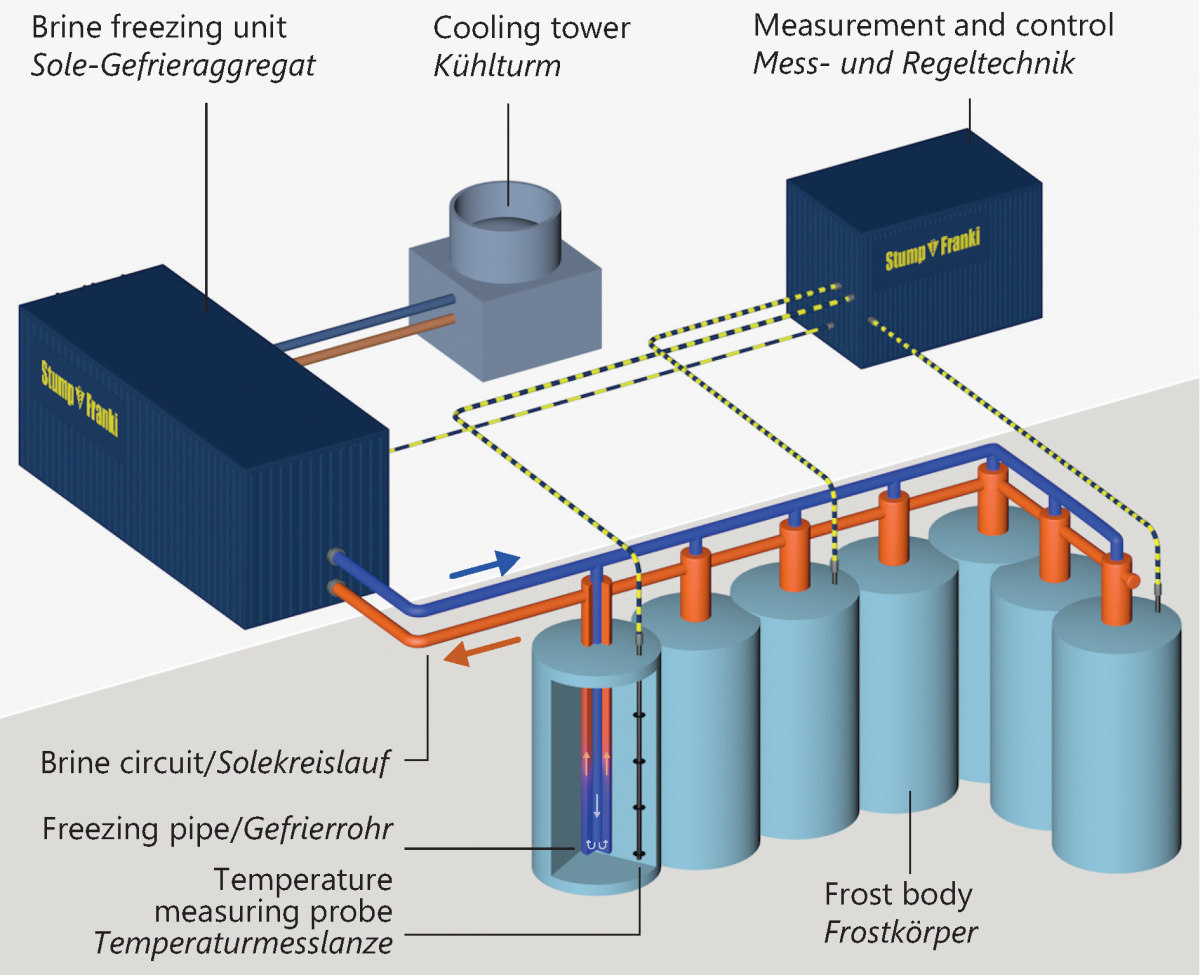

There are two different ground freezing methods in use. On the one hand, cryogenic liquid nitrogen, on the other hand, aqueous salt solution, the so-called “brine”, can be used as a coolant. In both variants, the cooling is supplied via freeze pipes and freeze lances inserted into the ground.

Ground Freezing Work in the Connection Area to the Existing U5 Tunnels

In the course of the double-track extension of the main line B in the Frankfurt underground network, a freezing measure was required in the connection area to the existing tunnels at the square „Platz der Republik“. Stump-Franki Spezialtiefbau GmbH, a subsidiary of Porr Deutschland, was commissioned with this work. In the case of ground freezing, heat is extracted from the ground by supplying cold by means of drilled-in freeze lances. The groundwater freezes and individual ice cylinders are formed, which increase in diameter around the freeze lance over time. By stringing these ice cylinders together, closed, watertight systems can be created that effectively stabilise the ground.

Schematic illustration of brine ground freezing

Schematic illustration of brine ground freezing

Credit/Quelle: Stump-Franki

Calcium chloride brine (CaCl) was used as the “carrier” of the freezing temperature in the U5 construction project in Frankfurt (down to approx. -37 °C). For longer operations, ground freezing with brine is the more economical option. Nitrogen, a relatively expensive refrigerant, is primarily used for short-term special applications. Due to the particularly strong and fast freezing process, nitrogen freezing is well suited, for example, for streaming groundwater.

Complex Monitoring

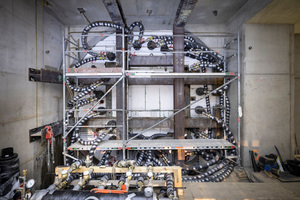

The basic work steps of ground freezing include drilling the boreholes, which are converted into freezing pipes, the installation and connection of the cold carrier piping system, the commissioning of the appropriate ground freezing unit (FU) and the operation of the freezing system.

Another important step in the construction of the U5 in Frankfurt was the installation and implementation of the monitoring system. System parameters of the FU and the brine flow were monitored – especially the scheduled build-up of the frost body. Thermal calculations resulted in forecasts regarding the duration of the frost body build-up, which then served as a reference for the monitoring. In addition, the required freezing energy was determined in order to be able to calculate the sufficient strength of the necessary ground freezing unit.

Ground Freezing Boreholes

Based on technical and economic considerations, an investment was made in a brine freezing unit with a cooling capacity of 140 kW for the freezing measure at hand. This capacity resulted from two redundant and independently controllable refrigeration circuits with capacities of 70 kW each.

The freezing boreholes posed the most difficult part of the tasks, as very high demands had to be made on the accuracy and the impermeability of the boreholes. In addition, the boreholes had to be drilled against pressing groundwater using blowout preventers and standpipes that had to be installed beforehand. Here, precision work was required – many working steps as well as very cramped working spaces made the task more difficult.

Testing and Commissioning

After completion of the drilling work including re-measurement and a pressure test, the boreholes were equipped with freeze heads, freeze lances, temperature measuring chains and drainage pipes for pressure relief and connected to the freezing system. After further preliminary system checks the refrigerant could be admitted to the system and circulated. The FU was started and cooled the brine in the refrigeration circuit back down to the target temperature after returning from the freezing pipes.

Active Cooling Reduces the Freezing Time

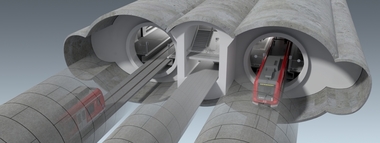

In the U5 construction project in Frankfurt, the tunnel boring machine drove into a funnel of previously frozen soil bodies. For this reason, the freezing pipes have a special collar-shaped layout. A concept of active cooling developed by Stump-Franki, which additionally uses the residual cold of the previously used and thus warmed brine from the freezing pipe return, was installed on the surface of the stop wall and supported the freezing process. The freezing time until the required temperatures and ice body diameters were reached amounted to around 50 days. With the successfully executed ground freezing, the ground was sealed and solidified so that the tunnel excavation could be carried out safely under compressed air. Thanks to the two redundant cooling circuits and an emergency power supply, the ice formation was secured at all times.