Micro TBM Navigation with Gyrocompass in Abu Dhabi

In autumn 2018 the Abu Dhabi Sewerage Services Company (ADSSC) commissioned the UK construction company Joseph Gallagher International with the project “Construction of Deep Gravity Line” in Abu Dhabi (United Arab Emirates). The construction phase, scheduled for a duration of 20 months, started in December of the same year. The project comprises altogether 25 km of microtunnelling with nominal diameters from ID400 to ID2000, the excavation works are carried out with five ISEKI and three Herrenknecht machines. The geology consists of mixed sands and calcite.

The project section described in this article is a 520 m long ID1800/OD2220 drive, excavated by an ISEKI TBM. Owing to the difficult climate conditions – the temperatures measured in the initial excavation pit were at approximately 40 °C, those in the TBM went up to as much as 58 °C – and due to the high level of humidity inside the pipe, the laser used for navigating the TBM reached its limit despite its good quality. After a distance of just under 400 m had been covered, the diameter of the laser spot was approximately 80 mm wide, with the spot position being highly unstable. The position and the altitude shown on the laser display varied to such a degree that it was sometimes practically impossible to exactly control the driving operation. For this reason, site manager Simon Millard urgently needed a solution enabling him to drive the remaining 120 m of the tunnel, and he chose the new NAV24 navigation system, recently launched by Tunnel24, a company with headquarters in Wesel, Germany.

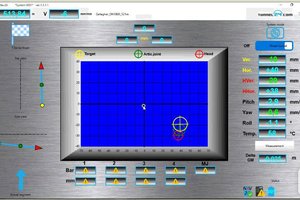

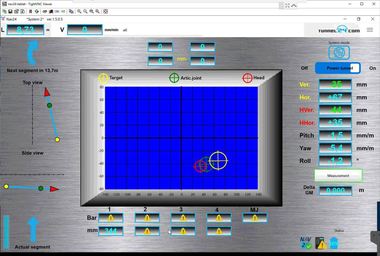

System Components

The core components of the system comprise the MWDR gyrocompass, performing non-stop measuring operations, combined with a high-accuracy electronic hose levelling unit that allows for precise measurement to the nearest millimetre irrespective of drive length. The system components are connected via a CAN bus system, with the computer being well shielded and protected in the solid WS box made from metal. Operating the system is a rugged tablet PC, a so-called “toughbook” with a Windows 10 OS. This toughbook is connected to the WS box via a wireless LAN. This solution affords the machine operator maximum flexibility. Should the toughbook ever fail to properly perform its duties, any device supporting Windows 10 can replace it.

Drive lengths, pressure levels of intermediate jacking stations and main station can be integrated into the system as an extra. The system used in Abu Dhabi was permanently connected to the Internet so that it could be monitored and supported from Germany at any given time.

Installation and Support

The NAV24 system installation and support are ensured by means of a cooperation agreement concluded with the German company Poltinger Precision Systems (PPS) – an established expert for TBM guidance systems with well-known customers such as the construction companies Hochtief, Implenia, Marti and Porr and the TBM manufacturer CREG, Robbins, CRGCI and Herrenknecht.

As soon as the system had arrived in Abu Dhabi it was installed during the on-going tunnel driving operations and at high ambient temperatures within one day. Subsequently the new navigation system was calibrated and set up. The on-site installation of the system was performed by PPS with the support of Tunnel24. PSS also familiarised the local surveyor with the system setup and calibration. Everything went off without a hitch so that regular driving operations could be resumed after two days. The breakthrough into the target pit took place on 20 September 2019; with the exact target location being hit after the section of 520 m had been driven.