New Development of an Annular Gap Mortar for mechanizedTunnelling

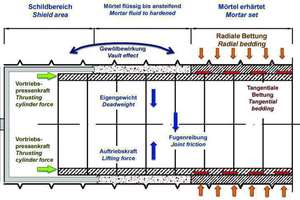

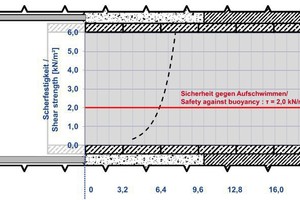

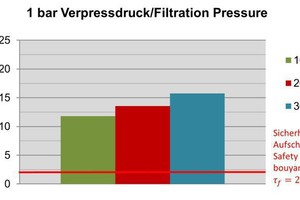

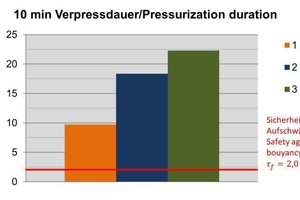

Lifting forces act on the segment rings once they vacate the shield tail during shield drives involving segmental lining and annual gap mortar grouting. These can lead to pronounced misalignments of neighbouring rings and damage to the annular joint as well as leakages. Stiff bedding for the young segmental rings can be assured at an early stage thus reducing flotation thanks to optimization of the targeted new development based on an explicit profile of requirements.

1 Introduction and Motivation

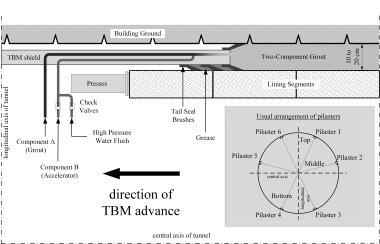

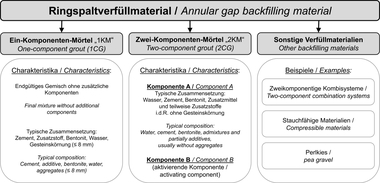

During mechanized tunnelling employing shield driving machines, the prevailing soil is removed at the face by means of a cutting wheel. The surrounding soil is supported temporarily with the aid of the shield jacket and the final tunnel lining executed in the form of reinforced concrete segments. The annular gap created between the excavated cross-section and the segmental lining is filled continuously during the mechanized drive in order to avoid harmful soil deformations and ensure that the segment rings are bedded as stiffly as possible. Conventional cement...