New MeasuringTechnologies for mechanised Tunnelling

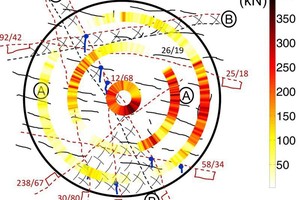

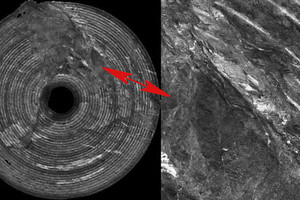

Efficient measuring technologies represent an essential prerequisite for successfully concluding tunnel projects. Ongoing accomplishment of such projects spurs on the development of new measuring technologies and the optimisation of existing ones. Current innovations focus particularly on the driving area of tunnel boring machines (TBMs). This article thus concentrates on a method for the continuous measurement of cutting disc forces, the geological 3D

documentation of the TBM face, using a camera system, and a 3D laser scanner system for

monitoring the tunnel lining. The new measuring technologies provide a rich field of research and contribute towards a deeper understanding of the interaction between TBM and rock.

Introduction

Tunnel boring machines (TBMs) are increasingly being applied for major projects such as the Koralm, Semmering Base or Brenner Base Tunnels, as they permit higher rates of advance to be achieved. However, the use of TBMs still involves ample optimisation potential. This relates for example to improved monitoring of the cutting process and the tools involved, a more objective, digital documentation of the face as well as better and more comprehensive evaluation of the deformations of the tunnel lining. This report puts forward new measuring technologies devised to increase this...

![Left: colour-coded relief presentation of the face in keeping with colour scale in [m] left, camera tracks (black concentric circles) and incipient rim area at the edge (dark blue); right: cutter head with blue coloured discs. The arrows indicate possible assembly points for the camera unit](https://www.tunnel-online.info/imgs/tok_662ee28d1c6f157b7e7102d2bc26498d/w300_h200_x400_y283_100845279_ad9e0ecfdb.jpg)

![Above: face images from Fig. 5 as colour-coded relief presentation (elevation scale in [m] above left); below: number of discs simultaneously not intervening over a full rotation of the cutter head owing to a cavity](https://www.tunnel-online.info/imgs/tok_d81a4eac713b9236c803433ac5a8c646/w300_h200_x400_y471_100845310_95eddc2ca6.jpg)