Special Foundation Works for the Schwarzkopftunnel Bypass

Between Würzburg and Frankfurt, the German railway company Deutsche Bahn has a route section newly built which is to replace passage through the Schwarzkopf Tunnel. The almost 160-year old tunnel no longer meets today’s requirements; passenger trains can only pass through the tunnel with reduced maximum speed. Heavy freight trains however need additional helper engines due to the steep inclination. Bauer Spezialtiefbau GmbH executed in a joint venture all required special foundation works which could not be constructed by mining method.

The upgraded Hanau–Nantenbach line is part of the Main Spessart route between Hanau and Würzburg. The route has been operational since the middle of the 19th century and is numbered among the busiest routes of the Deutsche Bahn network. As a central axis of long-distance and freight traffic it links the economic centres of the Rhine-Main District with Würzburg and the region of Franconia. A core measure of the upgrading is the bypass of the Schwarzkopf Tunnel between Laufach and Heigenbrücken.

In connection with the upgraded Hanau–Nantenbach line four new tunnels are installed for the bypass of the Schwarzkopf Tunnel. The Falkenberg Tunnel with its 2600 m will replace the Schwarzkopf Tunnel, the other three tunnels Hain, Metzberg and Hirschberg are newly designed and provide a flatter inclination (Fig. 2).

As part of a joint venture with Alfred Kunz Untertagebau, Baresel GmbH, Schälerbau Berlin and Leonhard Weiss GmbH & Co. KG, Bauer Spezialtiefbau GmbH together with the Bauer-subsidiary SPESA Spezialbau und Sanierung GmbH executed those special foundation works which were not constructed by mining methods: The excavation pits for the open tunnel sections were supported with pile walls, nail and retaining walls; moreover, an extensive pile foundation was installed using the continuous flight auger method (CFA-method) for the railroad embankment of the new train path. In addition there are soil nailings on a length of 550 m along the existing tracks, as well as struttings and temporary and permanent anchors. The piles having a length of up to 25 m were constructed in hard diorite, in gneiss and bunter, whereupon the embedment depth in very hard rock amounts up to 10 m. This rock has a strength of 100 up to a maximum of 270 MPa. For these demanding bores two BAUER BG 40, two BG 28 and one BG 20, five anchor rigs and some nail drilling and shotcrete rigs were used.

In order to prepare the mining works of the tunnel construction, portal excavation pits and shotcrete walls having a height of up to 30 m were installed for the tunnel portals. Apart from Bauer Spezialtiefbau GmbH mainly the Bauer-subsidiary SPESA Spezialbau und Sanierung GmbH executed these tasks. Especially the retaining with shotcrete panelling and slope protection with shotcrete and soil nailing had to be concluded. All shotcrete works were carried out using the wet-spraying method with manipulator and various base machines such as telescopic handler or excavator. Small diameter drilling rigs and excavators with attached feeds were deployed for the soil and rock nails. Depending on the subsoil and nail type, hydraulic top hammer or down-the-hole hammer were used for drilling.

To sum up, the following construction methods had to be applied for the special foundation works:

·52 000 m² king pile wall with wooden/concrete lagging,

·95 000 m temporary anchors, permanent anchors and GEWI-anchors,

·35 000 m² pile walls with 900, 1200 and 1500 mm pile diameter,

·40 000 m pile foundations using the continuous flight auger method (CFA-method), having pile diameters of up to 750 mm,

·4000 m vibro displacement,

·32 000 m² soil nailing with shotcrete walls,

·3000 m² sheet pile wall installation.

A total of 11 000 t reinforcement were installed.

Soil Nailing in the Area „Tunnel Hain“

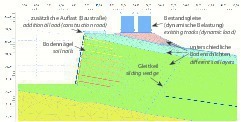

The tender documents included the construction of pile walls with two strutting layers serving as excavation pit support on a length of 750 m. Due to a side offer, however, the scope was changed in such a way that – corresponding with the tender documents – only a contiguous pile wall on a length of 220 m, having a pile diameter of 1200 mm and a pile length of up to 22 m as well as two strut layers, had to be constructed. The remaining 530 m track length were executed as sloped excavation pit consisting of nail wall (trackside) and slope hill-facing (40 to 45 degrees inclination) (Fig. 3). The nail wall having a height of up to 16 m required the installation of ten nail rows and a nail length of up to 12 m. The shotcrete had to have a thickness of 15 to 20 cm.

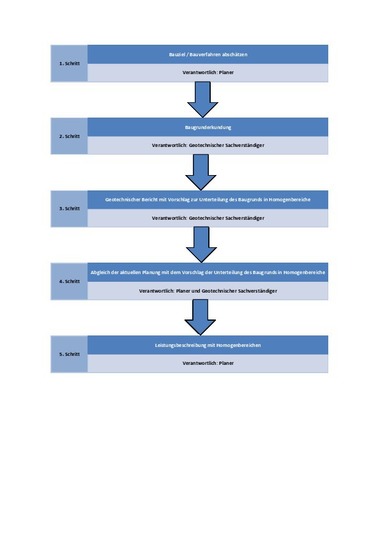

Planning Soil Nailing

Soil nailing was dimensioned using a 2D FE-model (Fig. 4). Modelling was based on the data by the soil analysis and the calculation parameter of Prof. von Wolfersdorff. The load assumptions to be considered were determined according to the relevant requirements by Deutschen Bahn AG. On the basis of the planning results limits for the deformation of wall and the existing trackbody were identified (warning and alarm values). Following the standard, the relevant monitoring method was used, and the corresponding measuring levels were fixed with a distance of 10 m. In sensitive areas, the geodetical surveillance was carried out daily and in less sensitive areas weekly.

Execution of Soil Nailing

For soil nailing, a bar-shaped reinforcement, the so-called soil nail, is installed in the natural ground. Thus, the tensile and shear strength of the soil body is to be increased. In this way, a composite body is formed which is similar to a gravity dam in its structural behaviour. To carry out soil nailing, the first soil layer is excavated at the beginning, then the shotcrete surface is added with reinforcement. Now the soil nails are installed. The bores of the soil nails are grouted with cement mortar. The soil nails are firmly but without pretensioning connected with the shotcrete surface. Subsequently, the next layer is excavated. Figure 5 shows the soil nailing with shotcrete surface for the Tunnel Hain. The bores were executed using a small drilling rig. The nail length amounts up to 12 m. According to the admission of the Deutsches Institut für Bautechnik (Centre of Competence for Construction) load tests with up to twice the work load were carried out at 95 soil nails (320 kN test load) (Fig. 6).

Trough Construction at the Example „Trough Aussiedlerweg“

In the range of the structure „Trough Aussiedlerweg“ the area is up to 10.6 m above the planned new railway line; therefore a support wall for cutting into the area along the total length of 380 m was necessary. According to the tender documents and the project award, a secant pile wall having a diameter of 1200 mm had to be constructed for the trough which had to be tied back twofold and in parts also threefold. Pile length amounts up to 18 m. Piling was executed in the period 1 May to 30 October 2014. Two BG 40 drilling rigs were used for constructing the tied back secant bored pile wall. The drilling works for the pile installation comprised bores into augen gneiss, having a strength of up to 80 kN/m² and a soil class between six and seven. Later on, the anchoring works were carried out in the period of October 2014 to April 2015. The pile wall was tied back with two anchor rigs of the type Klemm KR 806 using the overlapping drilling method with auger and/or down-the-hole hammer. In this area apart from weathered rock also very hard rock was found in parts. The overlapping drilling method for anchor bores was used on almost the complete project site.

Dismantling Measueres and Test Operation

Bauer Spezialtiefbau’s essential works were completed by end of 2015. The dismantling measures still required will be executed until the middle of 2017. The bypass project has been under construction since 2013. With the tunnels being equipped for operation, the project is on schedule with regard to time and budget. In 2016 the Deutsche Bahn finished the structural works and the installation of the slab track as planned. The test operation is due to begin in May 2017, and the bypass is scheduled to be put into operation by the end of the year.