Classifying the Subsoil into Homogeneous Areas for Drives Using Shield Machines

Division of the subsoil into homogenous areas is becoming increasingly important for drives using shield machines in soft ground. Within the scope of this report therefore, geotechnical key parameters will be selected, which are significant regarding the use of the TBM and as a result also for classifying the subsoil into homogeneous areas. In addition, proposals for practical categorisation are provided. The article is intended to assist the geotechnical expert as well as designers and clients to classify the subsoil in keeping with the given boundary conditions in an appropriate manner. Combined with analyses to be carried out in accordance with the recommendation on selecting tunnel boring machines by the German Tunnelling Committee (DAUB), it furthermore attempts to provide the contractor with an appropriate basis for calculative and accounting purposes.

1 Introduction

Until German standard DIN 18312 for underground work and in turn also work involving shield machines was updated in 2015, the ground penetrated was classified for constructional purposes among other things according to DIN 18196 (cf. [1] or [2]). Classification into excavation classes for the specified construction method was undertaken in keeping with these data, whereby a distinction was drawn e.g. for the construction method with shield machine (SM) in keeping with DIN 18312:2012 resulting in:

Excavation class SM 1, excavation without support of the tunnel face

Excavation class SM 2, excavation with partially supported tunnel face

Excavation class SM 3, excavation with fully supported tunnel face

As a result of updating various standards of VOB/C in 2015 or their revision in 2016, soil and rock have to be categorised regarding homogeneous areas according to their state prior to being removed. The homogeneous areas are to be defined for instance for construction performances such as earthworks [3], pipe jacking operations [4] and underground work [5] (cf. inter alia [6]).

1.1 Definition of Homogeneous Area

The homogeneous area is defined as a spatially restricted zone, consisting of individual or several soil or rock layers, which possess – in the case of DIN 18312:2016 for underground work – comparable characteristics (see [5]). As a consequence, the classification of the subsoil into homogeneous areas depends on the selected technology. Should environmentally relevant constituents also come into play, they must be taken into consideration for the classification process. According to DIN 18312:2016 only the state prior to removal is relevant for classification into homogeneous areas (cf. [5]), although essential

alterations of the characteristics and states of soil and rock during and after removal, particularly in conjunction with air, water, supporting fluid or other conditioning agents must be mentioned.

The basis for classifying the layers of soil into homogeneous areas is provided by random subsoil analyses as well as the field and lab test normally undertaken. In this connection, margins for predetermined geotechnical reference values must be provided in the geotechnical report, whereby the classification into homogeneous areas can differ according to construction works. Based on these and further parameters, division into excavation classes takes place for full face excavation involving shield machines. In keeping with the currently valid

DIN 18312:2016, a distinction is made between the following excavation classes:

Excavation class VS 1, excavation without support of the tunnel face

Excavation class VS 2, excavation with fluid-supported tunnel face

Excavation class VS 3, excavation with EPB-supported tunnel face

1.2 Special Aspects during Shield Driving

The term homogeneous area has already been used for tunnelling projects in the past. In doing so, the tunnel route was divided into homogeneous areas, which described “an area with uniform rock characteristics” (cf. [7]). Consequently, only the geotechnical boundary conditions were considered for classifying the subsoil into homogeneous areas. The influence of the selected technology on classifying the subsoil was on the other hand, usually not decisive. Thus, it represents a major difference to the current definition of homogeneous areas according to DIN 18312:2016 with consideration of the interaction between technology and subsoil. The homogeneous areas according to DIN 18312:2016 serve to plan the deployment of equipment and in turn, to calculate and bill the construction work.

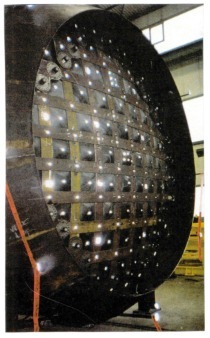

Situations can arise where two or more layers occur at the tunnel face in projects with alternating geological layers and resultant geotechnical characteristics of the layers around the tunnel alignment. These subsoil conditions referred to as a “mixed tunnel face” should be taken into consideration when classifying the subsoil into homogeneous areas according to DIN 18312:2016, on account of the frequently applied large diameters of the shield machines used and the resultant volumes of materials that are excavated. Owing to the geotechnical parameters there are various possibilities for classifying the prevailing soils into homogeneous areas, for which examples will be provided in the course of this article.

2 Specified Geotechnical Characteristics According to DIN 18312:2016

2.1 Overview of the Specified Parameters

Various characteristics or parameters with their margins must be provided for the homogeneous areas. Parameters must not necessarily be backed up with lab tests. They can also be estimated on the basis of experience. In the Infobox above the soil parameters are listed, for which margins have to be provided in accordance with DIN 18321:2016.

The parameters relating to the abrasiveness of the soft ground are new in Germany following the translation of French standard NF P 18-579. Based on corresponding tests, the abrasion value ABR can be established in [g/t] and the crushability coefficient BR in [%]. As the valid version of the standard does not foresee any classification of the results, pertinent literature (as e.g. [8]) should be used and cited for the interpretation or classification of the results. It must be observed that currently the test for determining the abrasion value ABR is being controversially discussed, as, among other things, owing to how the test is executed generally only a limited representative grain fraction is used and applying the test results in practice appears questionable (cf. [9], [10]).

2.2 Providing Geotechnical Key Parameters

It is advisable to consider geotechnical key parameters, which exert a substantial influence on classification for splitting the subsoil up into homogeneous areas (cf. [11]). The following list of key parameters are suitable for classification for drives using shield machines, as they must be specified as parameters within the scope of homogeneous areas (according to DIN 18321:2016) as well as for selecting shield machines in keeping with the recommendation on selecting tunnel boring machines from the German Tunnelling Committee (DAUB) [12]:

Grain-size distribution with percentage of fines

Consistency (consistency index)

Bulk density

Abrasion value ABR and crushability coefficient BR

3 Planning Aspects for Classification of the Subsoil into Homogeneous Areas

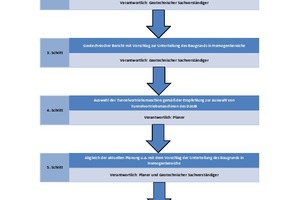

Essentially, e. g. in the case of construction services such as earthworks, the subsoil is classified into homogeneous areas after agreement has been reached between the client’s geotechnical expert and the designer. In order to visualise the collaboration in general between the designer and geotechnical expert, a rundown of this collaboration was developed [13], the basic contents of which are shown in Fig. 1.

The rundown foresees that the designer puts forward the objective as well as the proposed construction methods during an initial phase and then the subsoil exploration and Geotechnical Report are geared to them. On the basis of subsoil exploration, the geotechnical expert has to come up with a suggestion on classifying the subsoil in homogeneous areas. Subsequently, the proposal on the homogeneous areas is compared with the actual status of planning and a possible adjustment to the planning process ensues. Then, the performance specification follows, taking the defined homogeneous areas including any necessary adjustments into consideration.

4 Possibilities for Classification of the Subsoil into Homogeneous Areas for Shield Drives in Soft Ground Based on an Example

4.1 Boundary Conditions for the Example

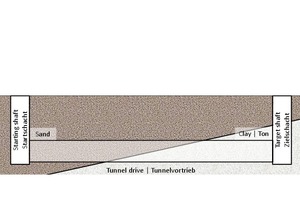

Based on an example, various possibilities for classifying the subsoil into homogeneous areas for shield drives in soft ground are presented. The project in question involves a drive where gravelly sands are present at the entire tunnel face directly prior to the start of the excavation. Thereafter, a drive with two layers (gravelly sands and clay) at the tunnel face is expected; based on the results of the subsoil exploration then a full-face excavation in clay must be accomplished. Fig. 2 shows the geotechnical longitudinal profile of the two layers to be penetrated. Installation class Z0 in keeping with LAGA M20 is supposed to be determined for both layers in the selected example so that there are no restrictions regarding reutilisation of the excavated material due to its environmental characteristics. Any further geotechnical parameters for these layers according to DIN 18312:2016 are disregarded within the scope of this example.

Based on the comparable characteristics for underground works, the subsoil is split up into homogeneous areas depending on the excavation technology. In keeping with [12] or the construction method put forward by the designer, the prevailing subsoil layers can be driven by applying shield machines with fluid-supported working face (excavation class VS 2) or with EPB working face (excavation class VS 3).

4.2 Possible Variants for Classifying the Subsoil into Homogeneous Areas

The two layers of gravelly sands and clays naturally possess different compositions with regard to the key parameter of grain-size distribution. As a result, in the case of shield machines with fluid-supported tunnel face clogging can occur in fine grained soils (cf. inter alia [14]), which merely play a subordinate role in soils without or with only a slight proportion of fines. The key parameter of consistency also has an important part to play in conjunction with clogging, as this can increasingly occur depending on the consistency index of the subsoil (cf. inter alia [15]).

In the case of shield machines with EPB-supported tunnel face clogging can also exert a substantiable influence, depending on the proportion of fines (cf. [16], [17]) whereas clogging does not usually occur in the case of drives in gravelly soils. Here, foam is added to the subsoil or excavated soil as a conditioning agent in order to improve the structural processability (cf. [18], [19]).

4.2.1. Variant 1

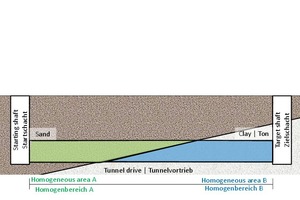

Consequently, the subsoil can be classified into homogeneous areas based on the key parameter of grain-size distribution. One possibility (Variant 1) in this connection would be classification in accordance with Fig. 3, in which the gravelly sands or the clay each represent an estimated homogeneous area. As far as the drive involving two layers at the working face is concerned, it is not possible to arrive at a clear allocation of the homogeneous areas in this way. For clear contractual calculation or accounting in conjunction with this means of classifying the subsoil into homogeneous areas, homogeneous areas A and B should be lumped together as one service item. In this case, driven metres or volumes of all excavated layers offer themselves as the unit of calculation. However, if other lengths or volumes are driven from those anticipated, owing to probable differences between predicted and actual subsoil layers, portions of the subsoil risk are transferred to the responsible contractor.

4.2.2. Variant 2

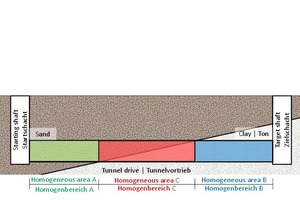

In order to consider service items for each homogenous area and in turn, reach a clear basis for calculation or the contract, further classification of the subsoil relevant to the key parameter grain-size distribution (Variant 2) as shown in Fig. 4 is suitable for the example. Whereas the full-face drive in sand represents homogeneous area A and the one in clay homogeneous area B, the drive with mixed tunnel face in the sand and clay is categorised as homogenous area C. For homogeneous areas A and B, the usual margins of the geological parameters or the key parameter grain-size distribution would be applied. The margin of the grain-size distribution of the material at the tunnel face in homogeneous area C, which lies between the two grain-size distribution curves of the layers, will, on the other hand, turn out to be very large. As a result, if necessary, a clear allocation of homogeneous areas A and B in contrast to homogeneous area C is difficult.

When classifying the subsoil into homogeneous areas in keeping with this method, service items are possible per homogeneous area and should be considered in accordance with the performance specifications. In this case, the volumes of the homogeneous areas being excavated serve as calculation units. The proportions of layers can be ascertained in homogeneous area C by determining the grain-size distribution. Eventual differences between the predicted and actual subsoil layers are taken into account contractually.

4.2.3 Variant 3

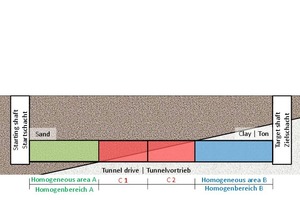

In order to consider the soil mechanical behaviour more thoroughly (or the key parameter consistency) in addition to the key parameter grain-size distribution and the clear calculative and contractual principles of the example, a further subdivision of homogeneous area C is advisable (Variant 3). In the case of an EPB shield and process-related mixing of the soils prevailing at the working face in the extraction chamber, the supporting material could possess either cohesive or non-cohesive characteristics depending on the mass ratios of the two layers in question. In order to be able to describe these characteristics more adequately, further classification of homogenous area C with the mixed working face provides the answer.

For this reason, homogeneous area C should be subdivided into homogeneous area C1, which e.g. possesses a dominant proportion of non-cohesive material, and homogeneous area C2, possessing a dominant proportion of cohesive material (cf. Fig. 5). When differentiating the homogeneous areas in keeping with this method, service items per homogeneous area are feasible and should be foreseen in the performance specifications. In this case, volumes of the layers being extracted serve as the unit of calculation, whereby the determination of grain-size distributions can be used to define the different sections within homogeneous area C. Eventual differences between the predicted and actual subsoil layers again are taken into consideration contractually.

Furthermore, classification in keeping with the key parameters consistency/bulk density or the key parameters abrasion value ABR and crushability coefficient Br would be theoretically possible.

5 Proposal for Subdividing the Subsoil into Homogeneous Areas

For the contractor, homogeneous areas must form the basis for planning the equipment used as well as calculating and billing the construction works. Additionally, the homogeneous areas represent the basis for selecting the tunnel boring machine. Both the geotechnical parameters of the prevailing layers of soil as well as the applied

technology must be considered for classifying the subsoil into homogeneous areas for projects involving shield machines. For this reason, the above-mentioned key parameters grain-size distribution, consistency or consistency index, bulk density as well as abrasion value ABR and crushability coefficient BR are suitable for the classification process.

As different layers are frequently found at the tunnel face in the case of drives involving shield machines, a detailed description of these transition areas with respect to the key parameters and the technology of the type of shield machine should take place. It is advisable within the course of compiling a clear basis for the calculation and the contract to include the homogeneous areas in each case as separate service items in the construction contract.

The approach shown in Fig. 6 is recommended for subdividing the subsoil into homogeneous areas when using shield machines in soft ground. In the first step, a geotechnical preliminary study according to DIN EN 1997-2,

Chapter 2.3 is carried out, on the basis of which the designer estimates the principle driving method (in this case, full-face excavation with shield machines) and essentially suitable excavation classes in accordance with DIN 18312:2016. These performances should be allocated to the service phases of basic evaluation and preliminary planning according to HOAI (German regulation on fees for architects and engineers). Then in step 2, the geotechnical main investigation according to DIN EN 1997-2, Chapter 2.4 in conjunction with DIN 4020 is executed for the conceptual design. The Geotechnical Report to be completed in step 3 also contains a proposal for subdividing the subsoil into homogeneous areas on the basis of the key parameters, related to the preferred excavation class (VS 1, VS 2 or VS 3). The main investigation is geared to ensuring that the designer selects the optimal shield machine or excavation class having observed the criteria cited in [12]. For this purpose, the subsoil along the alignment should be split up into further tunnel sections (or excavation sections) in order to appraise the system behaviour section-by-section (cf. [12]).

After determining the optimal excavation class, step 5 foresees a comparison of the current design with the Geotechnical Report, among other things with regard to classification into homogeneous areas and if need be, their adaptation. Subsequently, the designer compiles the documents for tendering the construction work in step 6. Thus, not only the excavation class and the above-mentioned tunnel sections but also the homogeneous areas are taken into consideration when pricing the service items in the specifications.

Thanks to this procedure it is expected that the special aspects of mechanised tunnelling in soft ground are

taken into account appropriately as a result of coordination between the geotechnical expert and the designer. Furthermore, this procedure facilitates a suitable classification into homogeneous areas in conjunction with the recommendation for selecting tunnel boring machines [12]. In combination with the given project-specific boundary conditions and the excavation classes or excavation sections it also provides a clear contractual and calculation basis.

Characteristics and parameters to be provided for underground work with shield machines in soft ground according to DIN 18312:2016

Local designation; grain-size distribution with granular bands; mass fraction stones, blocks and large blocks; density; undrained shear strength; water content; plasticity index and consistency index; bulk density; abrasiveness; soil group; organic proportion; mineralogical composition of the stones and blocks; cohesion; sensitivity

![1 Recommended sequence for general collaboration between designer and geotechnical expert for classifying the subsoil into homogeneous areas, based on [13]](https://www.tunnel-online.info/imgs/1/5/0/1/6/2/8/tok_55c48f2fb4cccb5ffba9074ae9bf5050/w300_h200_x297_y421_tunnel_Homogenbereiche_Abb_1_V02_-4520924995864455.jpeg)