Process-Oriented Numerical Simulations and Track Design in Urban Mechanized Tunnelling

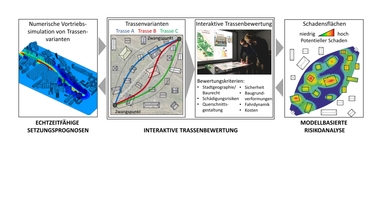

The development of a real-time interactive platform for digital exploration and evaluation of various tunnel alignments in urban areas provides a valuable tool during the planning process to support the decision-making. Such a platform should allow for visual exploration and parametric generation of feasible alignments considering all project design criteria. This article presents a digital interactive track design tool for collaborative planning processes, in which the simulation results, i.e. settlements, construction time, and the damage assessment of existing infrastructure, is integrated and visualized in real-time.

1 Digital Planning of Tunnel Alignments in Mechanized Tunnelling

A major challenge during the early design phase of tunnelling projects, particularly in urban setting, is the planning of an optimal tunnel alignment. The manifold impacts on this decision can be driven by economic interests, budget constraints, environmental requirements, schedules, and technical considerations. In the current traditional design process, the evaluation of various tunnel alignments is performed based on the engineering expertise in selecting the optimal low-risk and cost-efficient alignment using an evaluation matrix for the pre-selected alignments. Considering all the complexity of multiple design criteria, digital exploration and evaluation of various tunnel alignments in urban areas provides a valuable tool during the planning process to support the decision-making for optimal track design. This allows to investigate and assess the influence of various planning criteria and their mutual impact.

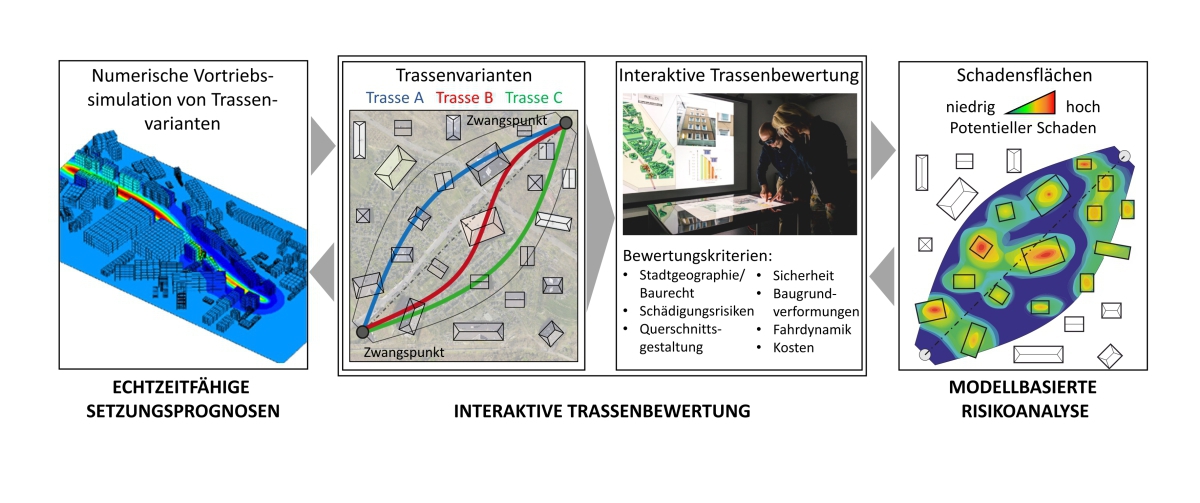

The development of such a digital tool requires an interactive digital platform for the planning and the evaluation of various alignments. The platform should allow for visual exploration and parametric generation of feasible alignments. Furthermore, it includes digital modelling methods and hardware devices that support the interactive generation of alignments, including multi-touch tables, to enable simultaneous modification and a collaborative planning process. For the assessments of individual tunnel alignments, simulation results, i.e. settlements, construction time, and the damage assessment of existing infrastructure are linked with the project design criteria during construction and operation phases and visualized in real-time. Figure 1 illustrates the interactive and collaborative digital tool for tunnel track-design.

1 | Interactive platform for real-time evaluation of various tunnel alignments

1 | Interactive platform for real-time evaluation of various tunnel alignments

Credit/Quelle: RUB

2 Interactive Exploration and Evaluation of Tunnel Alignments

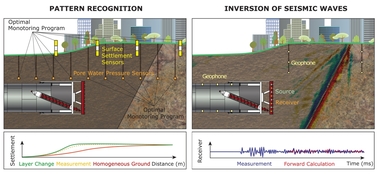

The interactive exploration approach is proposed as a continuous planning tool of alignments in mechanized tunnelling [1]. An investigation and evaluation of conditions and constraints makes it possible to derive information from existing planning data to support decision-making. In particular, the built environment and results of a subsoil survey are comprehensively investigated.

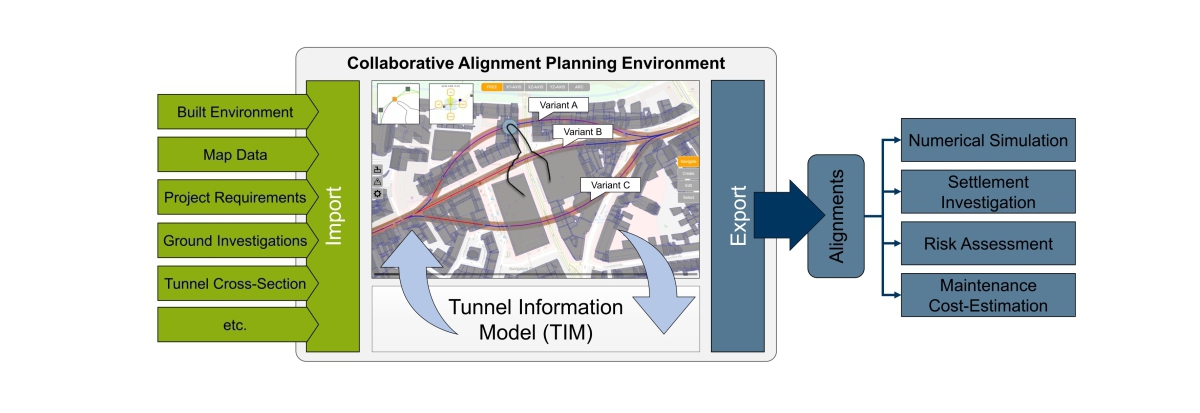

The concept is based on the extension of the Tunnel Information Model (TIM) [2] framework and complements components for alignment planning. The integration of a touch table and concepts for touch and gesture interaction are part of the Interactive Exploration concept to support collaborative planning processes. Thus, well-known strategies were adapted and adjusted to enable planning by touch interaction. The conventional alignment planning approach has been adapted, which causes challenges due to the underlying curve segmentation. To enable local modifications, required segments are approximated by free-form curves and continuously connected. Especially NURBS have been adjusted and utilized. Thereby, geometric dependencies are created, which are checked against project constraints and conditions, and which enable responsive feedback. The investigation of constraints and conditions is performed by using query languages for rule-based model evaluation. A query language provides the ability to perform structured queries on a tunnel model and to infer new properties. Such queries can be formally defined as rules and consequently evaluate results in an automated way. With this, not only planning-related properties but also geometric dependencies can be checked. This enables an interactive comparison of variants (Fig.2). Concepts for simulation and risk assessment are also included for an interactive BIM-based planning and execution.

2 | Representation of alignment variants in an application for collaborative planning

2 | Representation of alignment variants in an application for collaborative planning

Credit/Quelle: RUB

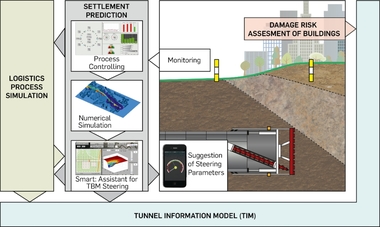

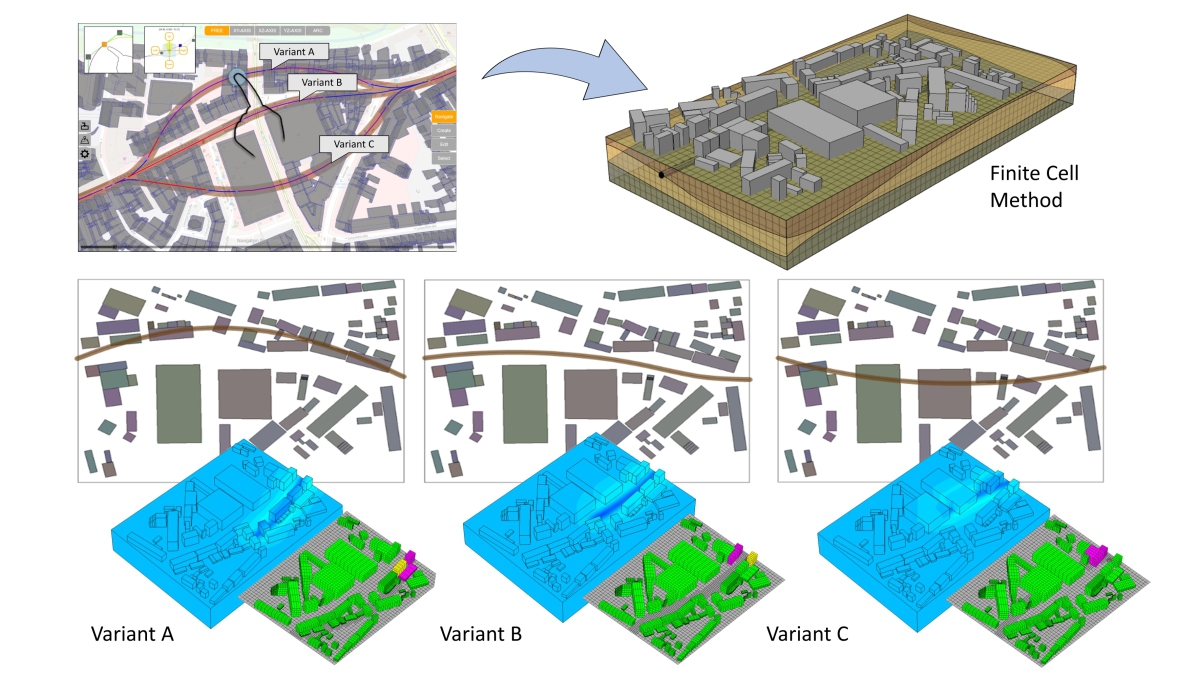

3 Process-Oriented Simulation Model for Mechanized Tunnelling

For the assessment of the impact of various tunnel alignments, e.g. settlements, face stability, damage criteria, a process-oriented finite element (FE) simulation model for mechanized tunnelling (ekate) [3] is integrated in the interactive platform for tunnel track design. For this purpose, the FE-simulation model is coupled with the Tunnelling Information Model (TIM) [2]. This coupling allows automatic extraction of all relevant information (geology, alignment, lining, existing infrastructure, material, and process parameters) needed for the numerical model and subsequently performing a FE analysis for the tunnel drive [4]. To further enhance the efficiency of model generation for various tunnel alignments, a new modeling strategy is integrated in the FE-simulation model that is flexible to incorporating various tunnel alignments without requiring generation of a new finite element mesh for each path. This new strategy employs the finite cell (FC) method, which is based on a structured regular mesh of the entire domain and does not require the spatial discretization to follow the geometry of the (moving) excavation boundaries (Fig. 3). The boundaries of the soil layers, the excavation geometries and the tunnel alignment are directly transferred as NURBS surface geometries in the ekate-software without any need for a new mesh generation. Adaptive Octree algorithms with quadrature refinement is used to realize geometric and material boundaries in the model.

3 | Automatic generation of FC simulation model for various tunnel alignments based on TIM CAD models

3 | Automatic generation of FC simulation model for various tunnel alignments based on TIM CAD models

Credit/Quelle: RUB

This procedure is a pre-requisite to enhance the interoperability with the interactive track design tool. On one hand, the FE-simulation can be invoked autonomously for various tunnel alignments. One the other hand, the results of the numerical simulation are automatically incorporated in the digital planning tool. To enable real-time interaction with the platform, a surrogate modelling approach for various tunnel alignments can be trained beforehand based on synthetic data from FE-simulations and then integrated in the interactive platform.

4 Model-Based Evaluation and Risk Assessment

The determination of a preferred alignment variant is not only based on the induced settlements, but also on the damage potential of existing structures and on the project duration and costs. Using the results of the FE -analysis for various tunnel alignments, the damage risk of the above ground structures is assessed by strain limits developed in the format of damage contour maps considering the inherent uncertainties [5]. This damage contour map is integrated and visualized in the interactive planning tool for the evaluation of the tunnel alignment.

For the comparison of the project duration for different alignments, process simulations can be used. Within the framework of SFB 837, logistics simulation models have been developed which enable a prognosis of the project duration considering uncertain input parameters. In the models, the interdependencies of the production and logistics processes are displayed and the effects of the crossed soil layers on the maintenance positions and durations are considered [6]. By linking the simulation results with the interactive planning tool, the project duration can be used as a further evaluation criterion for finding a preferred tunnel alignment.