Process Simulation as a Planning Tool: Logistics Optimisation for the Fürth Freight Train Tunnel

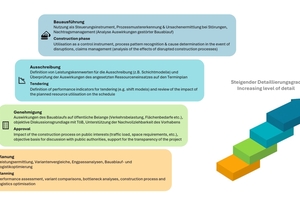

The implementation of large-scale projects requires robust planning that takes into account various target variables such as sustainability, construction time and cost. In recent years, the demands on planning and execution have increased due to greater emphasis on the interests of public authorities (noise, dust and traffic emissions) and new legal regulations (German Substitute Building Materials Ordinance ‘ErsatzbaustoffV’). Process simulation is a suitable method for designing the construction process as efficiently and robustly as possible in the early stages of planning and for holistically assessing the impact of changes in the planning process on execution. Using the Fürth Freight Train Tunnel project as an example, this article shows how simulation-based planning methods can help to transparently present and analyse interfaces in logistics planning, realistically model construction processes and thus support informed decisions.

1 Introduction

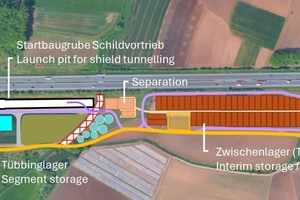

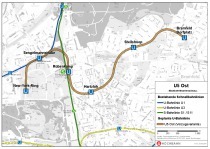

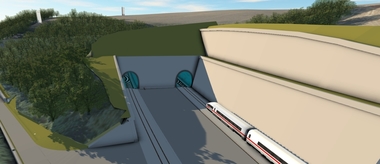

As part of the large-scale VDE 8.1 Nuremberg–Ebensfeld project, DB InfraGO is commissioned by the German government to expand and construct a high-performance railway line between Nuremberg and Erfurt. One sub-project is the construction of the new double-track freight line 5955 from Nuremberg-Kleinreuth to Erlangen-Eltersdorf, which is intended to relieve the heavily frequented main station in Fürth (Bay) of freight traffic and thus create additional capacity for passenger transport. A central structure of the section is the Fürth Freight Train Tunnel, which is to be constructed...