Injection Technology Workshop: Practical Learning at the Recklinghausen Training Mine

On June 25 and 26, 2025, an in-depth workshop on the highly topical subject of injections in structural engineering took place at the Recklinghausen Training Mine. Around 100 experts from engineering offices, construction companies, material manufacturers, and clients exchanged information on the latest developments, materials, processes, and practical experiences during the two-day workshop. The safe and permanent repair and upgrading of structures through injections is a central pillar of structural maintenance, which is why in-depth technical discourse is of fundamental importance.

The chosen venue, the Recklinghausen Training Mine, not only provided an impressive backdrop, but also underscored the highly practical nature of the workshop, which was organized jointly by STUVA (Research Association for Tunnels and Transportation Facilities) and Webac. This became apparent on the very first day during an expert guided tour of the mine, which gave participants an insight into the particular challenges of underground construction and the maintenance measures required there.

Technical Presentations and Demonstrations on Material Application

A series of high-caliber technical presentations formed the core content of both days. These covered a broad spectrum, from fundamental material properties and quality assurance to special application techniques, complex damage patterns, and their repair. Among other things, a sustainable coating and injection technique for tunnel and foundation construction was discussed; a field report described the injection work carried out as part of tunnelling in a Scandinavian tunnel construction project.

In addition to new tunnel construction, injection technology is of course also an important module with regard to the rehabilitation of existing tunnels with highly diverse requirement profiles for the respective measures. In this context, another presentation at the workshop dealt with rock stabilization and ground consolidation for a retrofitted cross-section expansion in a railway tunnel.

The first day of the workshop ended with a convivial evening event in the historic Schwarzkaue, which is part of the preserved buildings of the former coal mine in Herten.

The second day continued the technical focus with further presentations on hybrid cement mortars, block backfilling in tunnel construction (full-surface cement injection between plastic sealing membrane and concrete inner shell) and other topics.

On both days, the program was supplemented by practical live demonstrations on test specimens relevant to construction under real conditions. This allowed participants to experience various injection techniques and material applications live and discuss them directly with the experts. These demonstrations provided a valuable addition to the presentations.

A Highlight of the Lecture Program:

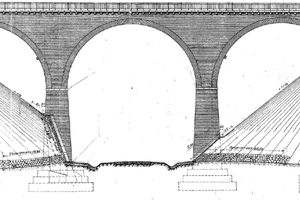

Rendsburg Railway Viaducts

In addition to fundamental aspects of injection technology, the numerous lectures also focused on challenging case studies from practice. Particularly noteworthy and a highlight for many participants was the lecture on the renovation of historic railway viaducts in Rendsburg. The project, carried out by Schwalbe-Baugesellschaft from Preetz on behalf of DB InfraGO, involved the repair of massive masonry arches that form the backbone of the rail freight connection to Scandinavia. Some of the structures, which are over 100 years old, needed considerable repair. A key factor in the success of this complex project was the use of a special Webac injection system. The speaker explained in detail how the precisely coordinated selection and processing of materials enabled the masonry to be permanently strengthened and

reinforced.

Cooperation is the Key to Success

A central theme of the presentation was the emphasis on the excellent coordination between all parties involved. The close cooperation between the contractor Schwalbe, the material manufacturer Webac (particularly in terms of technical consulting and material optimization), and the client DB InfraGO was identified as the key to the smooth running and high-quality results of the renovation work.

Following the presentation, a representative of an independent engineering office from the audience addressed the auditorium. This office had been commissioned by Deutsche Bahn AG to conduct a detailed examination of the renovation work in a final report. The expert expressed high praise for the chosen methodology, the quality of the execution, and the results achieved. This independent positive expert opinion underscored the significance of the project presented as an exemplary practical reference for the restoration of historic engineering structures.

High-Level Professional Exchange

The two-day workshop at the Recklinghausen Training Mine provided an excellent platform for intensive, high-level professional exchange. The combination of in-depth presentations, practical demonstrations, and the opportunity for direct networking in a unique environment was very well received by all participants.

Events such as this are indispensable for further developing the level of knowledge in the professional community on current injection techniques and for ensuring the long-term quality of building maintenance.

We would like to thank STUVA as the patron and sponsor of the event, all the speakers, the organizers of the training mine, and the active participants for this successful and informative event.