Innovative Sustainability Strategy Shapes Construction of the U5 in Hamburg

A holistic CO2 reduction strategy has been implemented since 2022 for the realization of underground line 5 in Hamburg. The pioneering approach of reducing construction-related greenhouse gas (GHG) emissions at an early stage through a targeted sustainability strategy with concrete measures in project management, planning and execution has received great approval from experts. The pilot project is a core element of the mobility turnaround in Hamburg to shift traffic, an important building block for achieving the city‘s climate targets and at the same time poses major challenges for the structural implementation in the heart of the northern German city. The approximately 25 km long U5 line begins in the north-east of the city and, with 22 new stations, will also connect previously unconnected districts to the public transport network. It will be put into operation in stages by 2040 and will carry around 315 000 passengers a day once it is completed.

1 Project Presentation U5

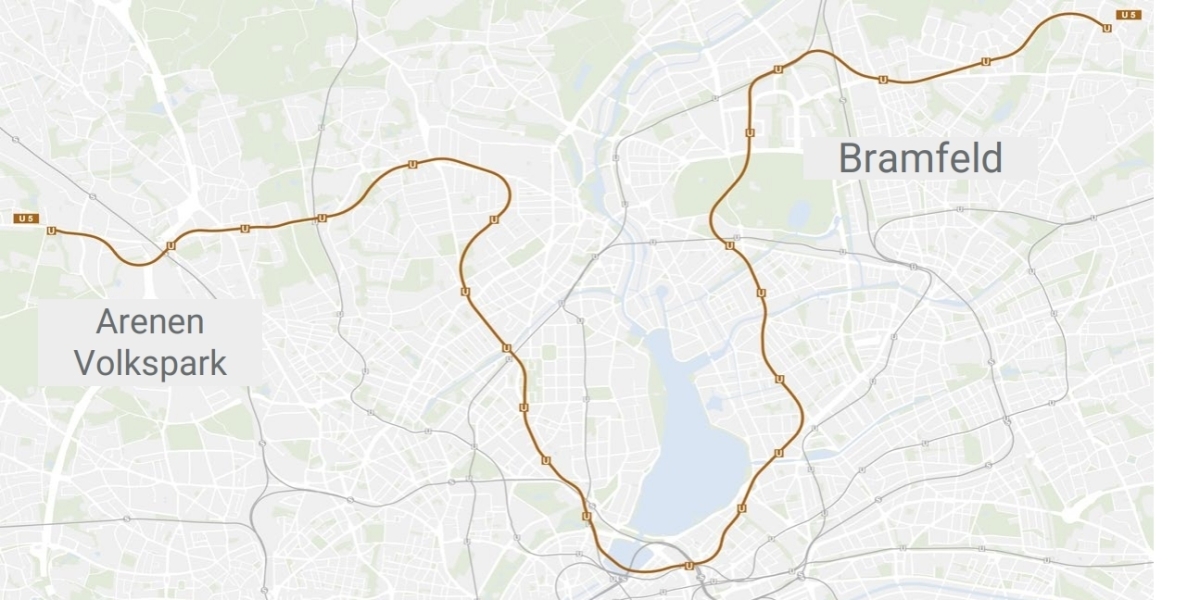

The new subway line 5 connects the east of Hamburg from the “Bramfeld” station via the main railway station to the “Arenen Volkspark” station in the west (Fig. 1).

1 | Overview of the route of the U5 underground line in Hamburg

1 | Overview of the route of the U5 underground line in Hamburg

Credit/Quelle: Hamburger HOCHBAHN AG

Over a route length of around 25 km, 22 new stations are being built using the cut-and-cover method. The average depth of the platforms is approx. 15 m. The majority of the line is being excavated by TBM. Since the ground-breaking ceremony on September 30, 2022, the first, approximately 5.8 km long section between the Bramfeld and City Nord stations has been under construction. The remaining section of the U5 to the east and west of the Alster, up to the arenas, is currently still in the design planning stage. In future, the U5 will run as a fully automatic, driverless subway line every 90 seconds, covering the entire route in around 40 minutes.

The route of the new subway line 5 was chosen so that as many parts of the city as possible will have a rapid transit connection that cannot yet be reached via a light rail (S-Bahn) or underground station. In addition to connecting these important potential areas, which are currently still gaps in the network, the new U5 is also intended to relieve the heavily frequented MetroBus lines 5 and 6.

This will connect densely populated districts without rapid transit to the east and west of the Alster, as well as major educational and work locations such as Hamburg University and the Eppendorf University Hospital. It connects around 180 000 Hamburg residents to the rapid transit network for the first time or better. It also shortens travel times for passengers throughout the network, as it offers direct connections to other underground, S-Bahn and rapid transit lines at seven stations.

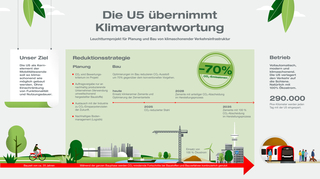

2 CO2 Reduction Strategy for the Planning and Construction of the U5

Mega infrastructure projects such as the U5 cause considerable CO2 emissions during the construction phase, which is why environmental and sustainability concerns play a much greater role than they did a few years ago. Since 2022, Hochbahn U5 Projekt GmbH has been focusing on a consistent CO2 reduction strategy for the planning and construction of its new subway line and is placing climate responsibility at the heart of its planning. The aim is to reduce CO2 emissions during the construction of the U5 by 70%, making the new line as environmentally friendly as possible. This means that instead of the 2.7 million tons of CO2-eq that would be produced by conventional construction methods, only 841 000 tons of CO2-eq will be produced. In order to achieve the 70% reduction target, significant optimisations have been made in the use of materials and construction methods, and sustainability has been included as an evaluation criterion in the ongoing planning of the U5. The earlier sustainability aspects are considered in the planning process, the better they can be influenced. The reduction strategy for the construction of the U5 is the first overall strategy for reducing CO2 emissions during the construction of a transport infrastructure project in Germany.

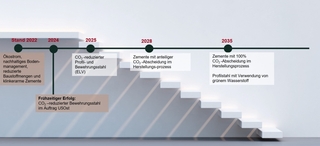

2 | Schematic representation of the CO2 reduction strategy for the U5 from 2022

2 | Schematic representation of the CO2 reduction strategy for the U5 from 2022

Credit/Quelle: Hamburger HOCHBAHN AG

A key aspect for the current and future planning steps is to intensively examine the possibilities for reducing greenhouse gas emissions during construction and to integrate them in accordance with the technical framework conditions. In this way, the CO2 impact of the overall project can be demonstrably reduced and potential reductions can be identified, particularly at material and component level and in construction logistics (Fig. 2). Other sustainability issues, such as resource conservation, production conditions, durability, ease of maintenance, usability and an active soil management concept, are also considered.

3 Initial Construction Work and Current Planning for the U5

3 | First construction section of the U5 between Bramfeld and City Nord (Stadtpark)

3 | First construction section of the U5 between Bramfeld and City Nord (Stadtpark)

Credit/Quelle: Hamburger HOCHBAHN AG

The U5 consortium (Arge U5), consisting of Ed. Züblin AG (technical lead) and Wayss & Freytag Ingenieurbau AG, began construction work on the first section of the U5 in December 2022 (lot 1) and August 2023 (lot 2) (Fig. 3). Here, four stations and six emergency exits will be built using the cut-and-cover method and one existing stop will be converted. A trial run between City Nord and Sengelmannstraße is planned for 2027 with passenger service starting in 2029, and completion of the entire first construction section of the U5 is scheduled for 2033.

3.1 Construction Method for Lot 1

The first construction phase begins at the “City Nord” station with central platform with a cut-and-cover tunnel. This is followed to the north by the double-track reversing and stabling facility in the direction of the existing above-ground Sengelmannstraße subway station. This will be modernized and converted for a platform-level transfer between the existing U1 line and the new U5. The U5 line will continue in the direction of Bramfeld with two steel trough bridges over Sengelmannstraße to the so-called wye, the transition to construction lot 2. The wye includes the tunnel structure east of Sengelmannstraße and the launch shaft for the tunnel boring machine.

3.1.1 Underpass Structure East of Sengelmannstraße

The Sengelmannstraße subway station is the only above-ground station on the U5 line. With a tunnel trough east of Sengelmannstraße, the line is lowered and leads into the tunnel. Here, the approximately 325 m long tunnel trough ends at the future launch shaft of the tunnel boring machine shortly before passing under the S-Bahn line. The trough will be constructed in sections using the cut-and-cover method. A diaphragm wall will be built and the floor will be concreted by special divers (Fig. 4). Work on creating the excavation pit began in October 2023. The U5 trough section is divided into five docks.

4 | View into the water-filled excavation pit of a dock in Sengelmannstraße

4 | View into the water-filled excavation pit of a dock in Sengelmannstraße

Credit/Quelle: Hamburger HOCHBAHN AG

The individual docks will be built partially offset to each other. The shell of the tunnel trough is due to be completed by 2027. The launch shaft for the tunnel boring machine will be located at the eastern end of the completed trough between the trough and the S-Bahn tracks, where the U5 tracks also meet.

3.2 Construction Lot 2

Lot 2 begins in the west with the launch shaft in the wye area and ends in the east at the target shaft, the later Heukoppel emergency exit. It includes the Barmbek Nord, Steilshoop and Bramfeld stations as well as five emergency exits. The underground stops, each approx. 200 m long, the starting shaft and the emergency exits will be built using the diaphragm wall/cut-and-cover or diaphragm wall construction method. The tunnel will be excavated to a depth of up to 30 m using a tunnel boring machine.

3.2.1 TBM Excavation

The approx. 3.4 km long tunnel will be excavated by a slurry shield TBM with an outer diameter of 11.70 m in four standard drives (636 m, 1011 m, 1402 m and 317 m long). The TBM will drive through the four backfilled excavation pits of the emergency exit structures. When the TBM reaches one of the three later stations, it exits into the completed excavation pit, is pulled through the excavation pit and begins the next standard drive on the other side. In its final state, the target shaft is converted into the Heukoppel emergency exit.

In order to drive the TBM safely in and out through the diaphragm walls of the launch shaft, the stations, the emergency exits and the target shaft, artificial soil blocks are installed as single-phase walls in the transition area between the diaphragm wall and the subsoil. Shield cradles and back-up cradles will be installed for the TBM‘s approach and passage through the excavation pits of the stations.

The tunnel shall be lined with a single layer of 0.50 m thick and 1.50 m wide, water-impermeable steel-fibre-reinforced concrete segments (7+0 segments per ring). Polypropylene fibres are used in the production of the segments to ensure fire protection requirements are met. The joints are sealed against the groundwater by means of pressurized water-retaining sealing frames.

3.3 Implementation of Sustainability Approaches in the Planning and Construction of the U5

Hochbahn U5 Projekt GmbH has developed a two-pillar reduction strategy for planning and construction in order to make Hamburg‘s mobility more environmentally friendly, and not just during the operation of the U5. The first pillar comprises the optimization of all planning services and the second the concrete minimization of CO2 during the construction of the U5. This has already led to successes in the use of materials and planning optimization for the first section of the U5 currently under construction. These are primarily the results of the consistent implementation of the following measures:

Contracts for construction are only awarded to sustainable companies that are committed to using environmentally friendly building materials, in particular by using the most environmentally friendly cements and steels available on the market

Saving material quantities through adapted construction methods and processes

Implementation of sustainable land management including logistics

Exclusive use of green electricity

For example, the mandatory use of environmentally friendly steel and cement has been included in the tenders and contract awards for the first section. As a result,

only reinforcement steel with highly recycled content (maximum 500 kg CO2 eq/t) has been used in the first two construction lots since 2024. In construction lot 2 (launch shaft U5 to Bramfeld station), only reinforcement steel with a maximum of 400 kg CO2-eq/t will be used – one year earlier than initially planned. By the end of January 2025, 32 000 tons of green reinforcing steel and 180 000 m³ of clinker-reduced concrete had already been ordered and partially installed. The successes are the result of an intensive exchange and close cooperation with the steel and concrete industry. The U5 strategy is having an impact and sending a strong signal to the industry, which in turn is increasingly supplying more environmentally friendly building materials.

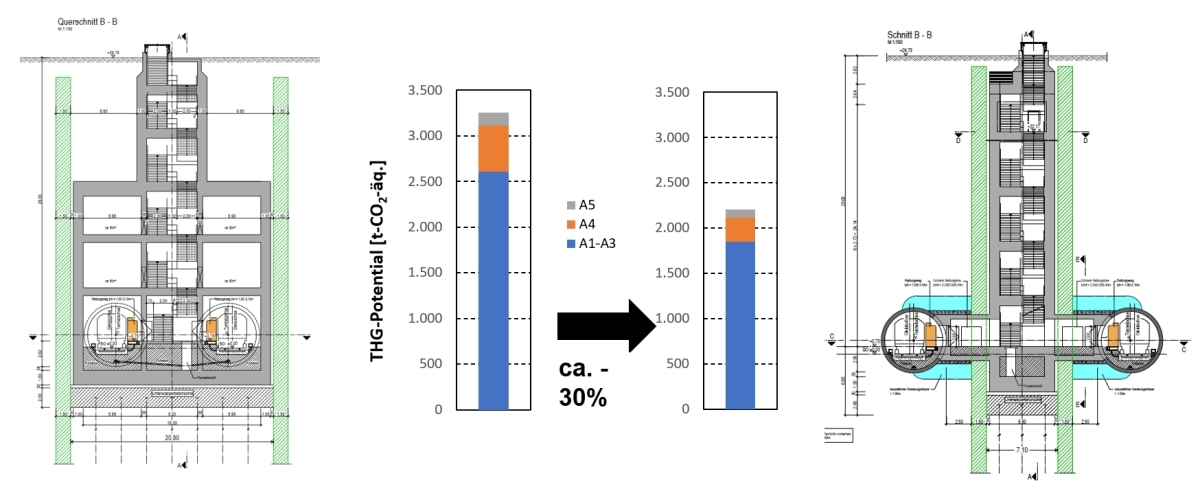

5 | Greenhouse gas reduction through material savings in planning

5 | Greenhouse gas reduction through material savings in planning

Credit/Quelle: Hamburger HOCHBAHN AG

By saving on materials, a reduction in GHG potential of around 30% was achieved in the design planning for the emergency exits in the City North to Jarrestraße construction section (Fig. 5). At the same time, the width and/or depth of the platforms at the stations has been reduced in some cases, which should also result in less material being used. These initial optimizations will also be applied to the other planning sections of the U5.

In addition to these successes, which have already been achieved in the planning phase, Hochbahn U5 Projekt GmbH is initiating the first individual approval in Germany for steel fibre reinforced concrete segments to be used in construction. Thanks to their material composition, these contain around a third less steel and therefore have a significantly better CO2 balance. The first pilot tests for the electrification of construction site logistics will also begin in 2025.

4 Outlook for Planning, Construction and Sustainability

While construction of the first U5 section is underway, the design planning for the remaining 17 km section is also continuing. In addition to the structural planning of tunnels and stations, this also involves construction methods and processes, logistics, traffic concepts and scheduling, as well as the identification and implementation of measures to reduce CO2 emissions. Along with the optimization potential already identified, further measures are being identified and implemented to bring about an additional reduction in CO2.

Joint reduction targets were discussed with the industry. In the course of the project, the first interim targets have already been achieved earlier thanks to the partnership-based cooperation between industry, construction companies and clients (Fig. 6).

6 | Reduction targets already achieved and set in various industries

6 | Reduction targets already achieved and set in various industries

Credit/Quelle: Hamburger HOCHBAHN AG

7 | Electrified truck in test operation

7 | Electrified truck in test operation

Credit/Quelle: Hamburger HOCHBAHN AG

Lead markets for the decarbonization of the cement, concrete and steel industries are being called for by industry partners and politicians. In Hamburg’s major U5 underground rail project, the requirement for sustainable products is being stipulated for the first time in tenders and implemented during construction.

In the future, electrified trucks and excavators will be used in test operation on the construction sites in the further course of the U5 construction project, thus gaining initial experience for their practical use (Fig. 7). U5 GmbH assumes that there is great potential for savings here, too.

U5 GmbH expects that even more potential can be leveraged at material level, which will become apparent in the further course of the project and have a positive impact on achieving the target of 70%. This finding is based above all on the ongoing exchange with industry representatives and the contractors of the first construction phase.

The savings in construction and planning are documented in the annual balance sheet in the sustainability report and have now also been included in the risk management for the U5. This makes it possible to transparently measure the CO2 reduction measures for the remainder of the project. The target scenario drawn up two years ago is consistently compared with the annual balancing of the CO2 emissions actually occurring during construction and the expected CO2 emissions for the further planning stages. This ensures ongoing quality assurance and the achievement of the reduction target.

This means that all the parameters for reducing CO2 emissions during the construction of the U5 are set: Sustainability has been integrated into the planning as an equally important criterion and is always taken into account. Thus, the maximum technically possible reduction measures can be considered at an early stage and ultimately implemented during construction. In addition, solutions are still being developed together with the industry to consistently drive forward the development of sustainable building materials. Based on the current status, it can be assumed that the level of CO2 emissions saved during the construction of the U5 can be further increased by the progress made in the coming years.