The Doha Metro –

Tunnelling in special Dimensions

Currently the Doha Metro is the world’s largest infrastructure project at the planning stage. 82 km incorporating 25 stations will run underground in Phase 1. These figures actually speak for themselves in fact. But as Qatar has been awarded the 2022 FIFA World Cup and the country intends applying to stage the 2020 Summer Olympics, Phase 1 must be accomplished within 7 years, something which lends special dimensions to the entire project and tunnelling in particular. For so far no experience has been gained in railway or Metro construction and consequently there is little expertise in tunnelling. As a result neither reliable references nor rules and regulations are available to be depended on: here a pioneering spirit is called for even in excess of what tunnellers normally display. Furthermore there are no technical values relating to tunnelling available for the soil apart from the fact that the groundwater is extremely aggressive. On account of the size of the project logistical problems and extensive interface problem complexes arise in conjunction with other major schemes taking place at the same time in the city of Doha.

1 Presentation of the Project

Doha, the capital of Qatar, is a densely populated, lively and fast growing city. One of the world’s most modern Metro and railway systems is to be set up here for the 2022 FIFA World Cup. Around 10 billion euros is to be invested in Phase 1. The goal is to establish a Metro system as well as a main-line network to link Qatar with Saudi-Arabia and Bahrain. The DB International is at present responsible for the planning and tenders for the construction measures to produce the Metro and railway system.

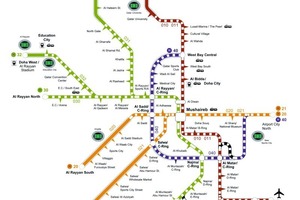

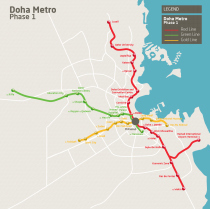

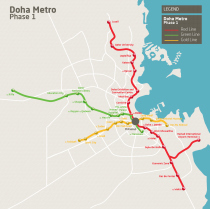

The complete route network (Fig. 1) is divided up into individual lines:

The Red Line (Sea Line) runs from north to south through the Emirate and thus forms the key line of Qatar’s transit system. It also connects the populated coastal strip with the capital. The Golden Line (Historic Line) mainly runs in an east-west direction and links Al Rayyan and Industrial Area North with the Airport. The Green Line (Education Line) runs from the south to the north-west and connects the large university complex Education City and the centre of Doha. The fourth and shortest line is the Blue Line (City Line). It runs along the C-ring in a circle from north to south within Doha thus creating intersections and transfer opportunities to the other lines.

The production of the entire network will be split into a total of 4 phases in keeping with the milestones provided by the major events.

• Phase 1: construction of the central stations and corresponding underground route sections for the Metro, which must be completed and commissioned in time for the 2022 FIFA World Cup

• Phase 2: development of the remaining links for the Metro lines within the city of Doha

• Phase 3: connecting the elevated and ground-level outer sections, towards the south and north

• Phase 4: building the high-speed and goods transportation network connecting up with Saudi Arabia and Bahrain

It is intended to construct and commission the 4 phases by 2050.

2 Geology

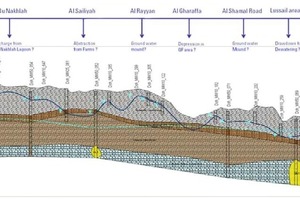

Qatar is an extended peninsular on the Arabian Peninsula pointing northwards into the Arabian Gulf. In geological terms with its position on the fringe of the Arabian Peninsula, Qatar is a part of the Arabian Gulf basin (Fig. 2).

Geological exploratory drilling and lab tests were initiated to get an exact picture of the soil in the project area. 123 drillholes between 25 and 70 m deep with an internal diameter of 63 to 84 mm were undertaken along the planned route alignment (Fig. 3). The water columns in the holes are measured after 24 and 48 hours. In addition to drilling pump tests are carried out in order to establish the permeability and connectivity of the groundwater table, something essential for the feasibility of the major portion of all the station buildings.

As no tunnel driven by mining means has ever been produced in Qatar, the geological values pertaining to tunnelling and special foundation engineering had to be determined by means of an extensive study. The soil in the project area mainly comprises fill material, Simsima Limestone, Midra Shale and the so-called Rus Formation.

Simsima Limestone forms the bulk of the surface. The stratification and lithology are not exactly known. It possesses a fine consistency, grainy, beige to pale brown and yellowish-brown. Furthermore Simsima Limestone is inadequately layered, contains crystalline limestone and dolomite rock with a large number of cavities and irregular fissures, which are often filled with soft siltstone. Occasionally thin layers of pale green or reddish-brown loam are to be found. The Midra Shale is a yellowish-brown and greenish-grey slate, which often contains fossils. Throughout the project area the Midra Shale alters in terms of consistency, colour, loam and limestone composition. The Rus Formation comprises whitish or yellowish dolomite limestone. The most recent rocks belonging to the Rus Formation to be found so far are located at Al Khor, in the north of Qatar. A special feature of the Rus Formation is the presence of various extensive layers of saline residues, mainly consisting of gypsum and anhydrites. The layers of gypsum can be up to 4 m thick and are mainly to be found in the southern part of the country at a depth of 20 to 50 metres. The lower layers of gypsum have subsequently become detached to a large extent as a result of circulating groundwater. They have ruptured at various points on account of the overlying layer thus also causing the ground surface to cave in. This occurs principally in the south and in the geographical centre of Qatar.

A karst system with sinkholes (karst funnels) is to be found throughout the country. A karst system is mainly associated with gypsum-based materials but it is also influenced by the existing carbonate rocks. Carbonate rock affords favourable conditions for tunnel driving. At other points however extreme conditions for tunnelling prevail given the presence of gypsum and anhydrites. The ground throughout the entire project area is highly heterogeneous, anisotropic involving karst-like fractures (Fig. 4).

Major seismic and tectonic activities were registered in the east of the Arabian Gulf (e.g. Iran). In Qatar itself such activities are rare so that it is classified in Seismic Zone Zero, which signifies that a very slight risk or none at all prevails. Volcanic eruptions and avalanches can also be precluded here.

3 Hydrology

The terrain is primarily low and flat. No waterways or lakes are to be found within Qatar. The slight precipitation, strong sunshine and extreme wind conditions cause great aridness. Notwithstanding an extremely high, natural groundwater table prevails.

The layer containing the groundwater lies between 5 and 50 m deep, with the groundwater table mostly being encountered after 5 to 15 m. The layer containing the groundwater is deeper towards the west. In similar fashion to the Simsima Limestone it is covered with a thin layer of in situ slate and a thin layer of fill material. On average the Simsima Limestone layer thickness amounts to 15 m with Midra Shale encountered underneath, which mainly serves as a sealing layer. These layers are entirely saturated and the groundwater is enriched by the seasonal rain and the permanent source provided by the Arabian Gulf.

The groundwater can change in future on account of new underground systems. In some cases it can rise by up to 8 m within 3 years (Fig. 5).

The groundwater contains very high amounts of sulphates (peak values of up to 4,000 mg/l) and chlorides (peak values of up to 54,000 mg/l). The groundwater exerts a corrosive effect on concrete and steel (Table 1) with a ph-value of 6.1 to 8.5 (Dammam) and 6.5 to 8.5 (Rus Limestone). The groundwater temperature averages 28 °C.

This all leads to a situation where no European norm can be applied for this aggressive groundwater and that in turn additional investigations must be carried out in the field of concrete technology (Fig. 6).

4 Tunnel Planning

Planning of the underground structures was embarked on against this background. The extent of planning for the Tender Design lies between the pre-planning stage and the planning design according to HOAI. The essential general conditions for establishing the tunnel cross-sections are laid down at a number of coordination sessions (Table 2).

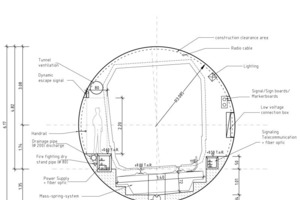

On the basis of these specifications the tunnel cross-section possesses an internal diameter of roughly 6 m (Fig. 7).

Furthermore additional investigations were carried out for the tunnel planning. Thus for instance the single or double shell construction method, the aggressive groundwater, the 120 years service life, the rate of advance, the connections for the cross-passages to the main tunnel and above all the question of maintenance and repair exert a massive influence on the choice of construction method. On account of the large number of different influences and the philosophy adopted for tendering these issues were not finally decided but passed onto the construction companies to process them in technical terms.

The tunnel safety issue also heralded in further discussions. A risk assessment and comparison of the double-track bore (as e.g. applied for the Dubai Metro) or 2 single-track bores (e.g. as according to TSI guideline) was initiated. Towards this end a cross-section of a double-track bore was devised. The study embraced aspects such as e.g. safety concept, construction costs, deadline, operation and maintenance, risk assessment etc. and was passed on to the Qatar Railway Company for processing. The client decided on a tunnel system with 2 single-track bores.

6 Logistics

Doha is a rapidly growing city. On account of the large number of other ongoing planning schemes and the execution of major projects, the question of interfaces with these construction projects is essential for planning the Metro. Furthermore it is important to come up with answers to the issue of producing a Metro and railway system in an urban area without impeding public life by gigantic construction schemes. Well thought out construction logistics provides the solution.

However it must be said that investigations have revealed that the areas required for the construction logistics in the centre of the city are either unavailable or only available to a limited extent. As a result the site installation areas within the city centre have to be reduced or individual site sections set up elsewhere.

Large, unused areas were found on the periphery of the city, which could serve as logistic areas for all construction site sections for the Metro. These areas were identified as so-called LPAs /Logistic Providing Areas) and included in the coordination round with all those involved. This solution would for instance facilitate materials being supplied just-in-time. However the present and future traffic situation represents an obstacle. The ASHGHAL, Qatar’s highway construction authority, is currently planning to substantially extend its road network within Doha, involving a similar investment volume to the one earmarked for the Metro. This is where the important interfaces lie, so that coordination between the various construction sections and those involved can be achieved. The plans for scheduling and the construction sections have still to be finalised. The complete integration of the excavation pits for the Metro within the road building works thus remains an ambitious target.

In order to draw up a concept for the construction logistics first of all possible construction methods were selected, as these influence the amount of time required on site. The quantities, which will accrue during excavation work and installing materials, were roughly estimated and tied to the overall logistics concept.

7 Project Timetable

On the basis of the cited diverse general conditions and the current planning a project timetable was drawn up in conjunction with the major milestones.

In this connection the typical dependencies of contract sections for infrastructure projects have to be considered as well as the constraints on deadlines, which result from the major events taking place in Qatar. It is possible on the one hand to attain optimisations by reducing the depth at which individual stations are built – however such optimisations are restricted on account of the other projects running parallel and in turn affect the minimum distances relating to the depth. The application of further tunnel boring machines (TBMs) would be an additional classic case of optimisation. This is made impossible in Doha’s case by the fact that more TBMs would also require more construction site installation areas, which do not exist in the city centre. Secondly the individual stations must be in a certain state of construction so that the TBMs can be drawn through them or can pass through the area in advance. This massively influences the chronological sequence of driving.

The Mushaireb Station (“Heart of Doha”) represents the core of the Metro network, where 10 TBMs are planned to arrive and which will subsequently be built upon to create the Dohaland urban development project.

8 Current Status and Outlook

The tender documents were concluded on April 2, 2012 and passed over to the pre-qualified bidders. Further work packages such as bidding for the technical furnishing, operational planning, the solid slab track and the surface route sections for the Metro will follow.

The DB International will continue to act as an important strategic partner for this unique project and advise Qatar Rail on all technical matters.