Dry Excavation with modified Tunnelling Jumbo

The complicated geology presents a challenge to man and machine for the new Stuttgart-Feuerbach rail tunnel, part of the major project Stuttgart 21. Owing to the rock that contains anhydrite, holes for excavation and injections must largely be carried out by the dry drilling method. As a result, modified tunnelling jumbos and vehicles with suction aggregates are deployed. The excavation is partially secured by pipe umbrellas.

Description of Project

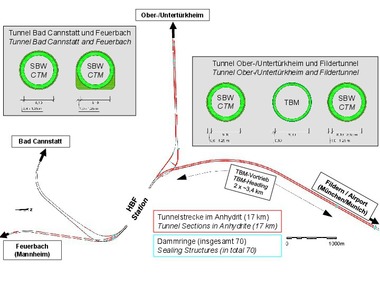

Since 2014, a railway tunnel with two single-track tubes with lengths of 2449 and 2426 m has been under production starting from Stuttgart-Nord. The tunnel for its part is an element of the major project Stuttgart 21, during which Stuttgart’s current Central Station – a terminal – is being transformed into a through station located at a greater depth. The new Central Station is to be connected underground by access routes coming from Feuerbach, Bad Cannstatt, Ober- and Untertürkheim as well as the Filder Plain.

A JV is charged with producing the Feuerbach Tunnel. It is comprised of three partners: Baresel GmbH (technical management), Alfred Kunz Untertagebau and Bertschinger Bau GmbH.

Anhydrite-bearing Gypsum Keuper

The biggest challenge of this tunneling project is concealed in the rock surrounding the tunnel tubes: it consists partly of swellable, anhydrite-bearing gypsum keuper, which can increase in volume by up to 70 % given appropriate amounts of ingressing water. This reaction could possibly lead to structural damage so that it has far-reaching consequences for tunnelling activities. The Swiss equipment provider Avesco AG modified drilling rigs from the Swedish manufacturer Sandvik for the excavation, which has been largely completed in the interim. This related to the tunnelling jumbo models DT820-SC, DT821-SC and DT922i. A first jumbo of Type DT620-SC was taken to the site to excavate the 319 m long heading from the eastern portal in November 2014. The two single-track tubes connect with this heading. As from mid-September 2015, two additional jumbos were deployed for the excavation at this point. Further jumbos were activated in late April 2016 as well as in May 2018. Thus, five jumbos are engaged on-site.

Project-specific modified Jumbos

Usually the boreholes would be flushed using water. However, as the use of water is precluded on account of the anhydrite rock, Avesco converted the jumbos completely for dry tunnelling. As this involves pronounced dust development, a powerful, mobile dust extraction system is essential.

In conjunction with the Swedish Ilmeg Products AB, Avesco devised a corresponding piece of equipment in keeping with the client’s specifications. A transporter – model Muli – made by the Austrian manufacturer Reform, houses Ilmeg’s dust exhaust system. It was assembled at Avesco’s headquarters in Langenthal, Switzerland. In addition, Avesco planned and produced the necessary suction heads for the drill carriages, which removed the dust directly at the drill hole. Tunnelling was executed in each case with a combination of jumbo and transporter with suction aggregate.

A further adjustment was required for converting to dry drilling, for before the water normally used to flush the drill holes flows through the drill bit, it is also used as a cooling agent for the hydraulic oil. This function is now taken over by the air cooler mounted on all the jumbos.

During the entire period of operation, Avesco tunnelling jumbo specialists cater for the machines’ service requirements. The drill hammers for their part are serviced in a section specially set up for the purpose for this major project at the company’s workshop in Langenthal.

Pipe Umbrella for the Tunnel Excavation

Furthermore, a special support for the vault was also necessary for part-sections of the tunnel project in Stuttgart-Feuerbach, A pipe umbrella was chosen for securing purposes which was also set up by means of Sandvik jumbos. A method devised by Avesco was applied for installing the pipes, which has proved itself in various international projects. The decisive advantages of this alternative lie in connecting the pipe segments with a bolting system and controlling all functions from the loading basket. There are pick-up forks at both sides of the basket for feeding the drill pipes. Transference to the carriage is undertaken by a feeder arm in a prism. This also serves to centre the pipes. The external pipe can be bolted together with the internal one in the series by means of the drill hammer using the hammer`s spigot end. In order to position the pipes, front centring must be taken over by a larger guideway. When the pipe umbrella is drilled, the process is controlled from the loading basket via radio transmitter. This solution devised by Avesco with radio control and automated bolting offers clear advantages vis-à-vis conventional methods particularly with regard to safety aspects.

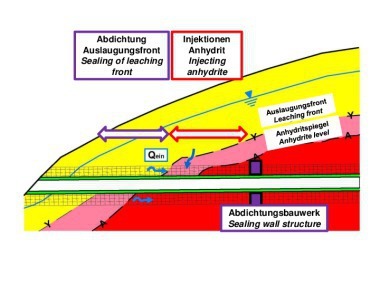

Measure to prevent circulating Water

In the course of the construction project it was decided to prevent water circulating to assure the safety of the tunnel structure and swelling of the anhydrite rock especially around the tunnel tubes. Extensive drilling work was also needed for this purpose, which also has to be carried out by the dry drilling method. A large number of up to 10.3 m deep holes are produced in the tunnel walls. These are then injected with acrylate gel or polyurethane resins. The intention is to prevent water circulating in the surrounding anhydrite zones in these injected areas.

Software Support for Drilling Work

Nowadays, tunnelling activities are practically unthinkable without effective software support. The Stuttgart-Feuerbach Tunnel is no exception. The process control and planning software iSURE devised by Sandvik is deployed in the jumbos there. iSURE enables drilling plans to be compiled with the desired position, angle and drill hole depth for every single hole. The plan is stored on the jumbo’s computer. The carriage is then manoeuvred into position and made ready for deployment. Every prescribed drilling point is located automatically and the drilling boom positioned exactly – also by automatic means. iSURE continuously processes numerous data during the drilling process and provides analysis functions for their evaluation. In this way, a drilling documentation can be very simply compiled for further on-site use. In Stuttgart-Feuerbach, the provision of this documentation was an imperative task for the JV.