GBT: Fitting the Cross-Passages with raised Floors

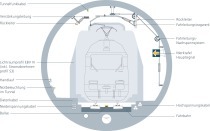

The 2 single-track tubes for the 57 km long Gotthard Base Tunnel are linked by means of 178 cross-passages. They serve as technical rooms for the rail engineering technology and as escapeways in the event of an emergency from one tunnel tube to the other. Now the cross-passages are to be fitted with raised floors on account of their utilisation by the rail technology.

Roughwork Furnishing

Prior to the rail engineering work being undertaken on the Gotthard Base Tunnel the roughwork fittings have first to be installed. They serve to assure the safety of persons and operations as well as providing a standard and low-maintenance solution for the entire Gotthard Axis. The cross-passages are set up at 330 m gaps and contain the following features:

– the bulkheads (sliding doors) to mark the ends of the tunnel tubes,

– the raised floors and

– the ventilation in the cross-passages (Fig. 1).

Raised Floors

The raised floor consists of removable floor slabs on a bearing structure with supports, which are placed on the cross-passages’ in situ concrete base. The cross-passages with an in situ concrete inner shell, which were driven using drill+blast in accordance with the tunnel excavation process, possess an up to 3.20 m wide and roughly 28 m long concrete base. Once they are lined the distance between the upper edge of the raised floor and the apex of the vault will equal 3.32 m.

Requirements

The technical demands on the construction materials and the bearing structure for the raised floor are high – especially with respect to:

– the climate expected in the tunnel with temperature fluctuations of –20 to +40 °C and an average air humidity of 70 %,

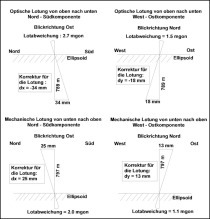

– the bearing capacity of 6 kN nominal and 10 to 12 kN/m2 area load as well as suction and pressure impacts from +10 kPa (Fig. 2),

– protection against corrosion-prompting air mixtures (iron dust from the abrasion of locomotives, wagons and rails as well as copper dust from the catenary wires) and

– fire protection.

Technical Application

All steel parts such as the sub-structure of the raised floor, connections, spacers, attachments etc. must be made of corrosion-proof material. As the sub-structure of the floor is expected to have a long service life it is made of stainless steel. The supports of the sub-structure are generally 40 cm long and are set 1.20 m apart lengthwise and 0.60 m crosswise. Like the contact angle they consist of steel 1.4403. All components of the sub-structure such as the contact angle, supports, lengthwise and cross struts are bolted together.

The entire low voltage and weak current installations were placed in the cross-passages by the rail engineering contractors. These include switching cabinets – also those for the facilities to close the bulkheads (sliding doors) and for the air-conditioning units –, which are delivered and assembled by special suppliers.

In order to facilitate the work in the cross-passages, the base slabs (Fig. 2) for the raised floor structure possess

– a grate pattern of 60 x 60 cm and

– a low weight (roughly 60 kg),

for they are only 5 cm thick, are comprised of glass fibre reinforced light concrete of high strength and are resistant against moisture and temperature fluctuations. They also fulfil the demands of fire protection (Class A1: non-inflammable). As the cross-passages are also used as escapeways, non-combustible material with low smoke development in the event of fire has to be applied for all components.

This also applies for the yellow ventilation grate (Fig. 3), which is set up at the edge of the cross-passage as a 35 cm wide strip and consists of glass fibre reinforced plastic of high quality. Together with the installed cross-passage ventilation it ensures there is constant air circulation in the sub-structure and serves to equalise pressure between the 2 air spaces above and below the raised floor and in this way prevents the base slabs from rising up in the event of open bulkheads and passing trains.

Installing the raised Floors

All 175 cross-passages of the Gotthard Base Tunnel with a total area of 18,900 m² are to be fitted with raised floors. The installation is carried out cross-passage by cross-passage during the completion of the tunnel roughwork. This requires close and coordinated collaboration between the Atel Burkhalter Bahntechnik AG and the AlpTransit Gotthard AG and the various roughwork contractors.

The actual rail engineering installations will first be mounted by the Transtec Gotthard JV (company for rail technology) once the entire roughwork jobs are concluded and the raised floor has been laid. As a result the individual raised floor parts have to be quickly disassembled at particular points according to requirement and subsequently reinstalled. Towards this end the installed slabs can be moved by a single person using a conventional raised floor lifter (Fig. 2). The storage and supplying of the raised floor elements at the installation yards in front of the tunnel are linked with out of the ordinary logistical demands.

Worthwhile Investment

The described raised floor system made of fibre reinforced, unfortified base slabs, grates made of glass fibre reinforced plastic and a stainless steel sub-structure exceeds – after tests by the Swiss Institute for Testing Materials (EMPA) at Dübendorf on behalf of the Burkhalter Bahntechnik AG – the requirements placed by the client, the AlpTransit Gotthard AG. This applies both to the pressure and point load as well as the corrosion resistance of the sub-structure and the ease of assembly. In other words, this type of raised floor represents a worthwhile investment in the future.