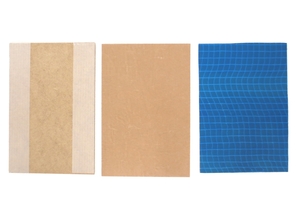

New mago Load Distribution Board

Until now, normal untreated hardboard has been used as load distribution boards. For the purpose of rationalisation, these boards are mostly glued on immediately after segment production. Then the segments are often stored for a few weeks or months exposed to the weather. With this procedure, it can occur that the load distribution boards, which consist of 93 % wood, absorb damp, swell up and can sometimes exceed the specified thickness by 50–80 %. In such cases, the function of the sealing is no longer completely ensured and water can leak into the tunnel. The remediation of such defects is...