Niagara Tunnel – providing renewable Power to Ontario for the next 100 Years

In March 2013, after eight years of tireless work, the largest hydroelectric project in Ontario in the past 50 years came to completion to the cheers of hundreds of onlookers. The new 10 km long tunnel is now channeling additional water from the Niagara River to the Sir Adam Beck Generation Station. Propelled by gravity, the water travels at a rate of 500 m3/s – fast enough to fill an Olympic-sized swimming pool in seconds.

The completion of this project is an exciting time for the Niagara region and its residents. Located just two hours from Toronto, North America’s fourth largest city, Niagara offers the best of metropolitan and country-style living. The excitement of having the world’s largest renewable energy project right under their feet only adds to the mix of activities that the Niagara area is known for: from Shaw Festival plays, to exploring the area’s wineries, to playing golf or visiting the majestic Horseshoe Falls. It’s also a great place to work. Niagara has recently transitioned from a manufacturing economy to a knowledge-based economy and small businesses are becoming integral to the region’s economy.

The Sir Adam Beck stations supply nearly 8 % of Ontario’s electricity. The new tunnel will add about 1.6 billion kWh of renewable hydroelectricity, enough energy to power a city with a population of about 400,000 – like Edinburgh/Scotland or Dresden/Germany – or 160,000 homes. Ontario currently has 200 waterpower facilities, with a total installed capacity of 8,000 MW – enough to power more than three million homes.

Ontario is rapidly emerging as an international hub for developing innovative clean tech solutions and delivering them to markets worldwide. The Niagara Tunnel Project, which was built at a cost of $1.6 billion, is part of Ontario’s long-term energy plan to produce and use clean and renewable sources of energy including wind, water, solar, biomass and biogas. Today, more than 80 % of electricity generated in Ontario comes from these clean energy sources, and by the end of 2013 Ontario will close down its last two coal plants in southern Ontario – a full year ahead of schedule. But it’s not just about power generation. The province is investing billion dollars to improve its smart grid infrastructure.

Like Ontario’s long-term energy strategy, the Niagara Tunnel project is ambitious in every way: in physical scope, technical complexity, and in its ultimate goal to convert water to energy at such a large scale. In fact, it is expected to serve Ontarians with clean electricity for more than 100 years – continuing Niagara Falls’ century-old history of supplying electricity to Ontario.

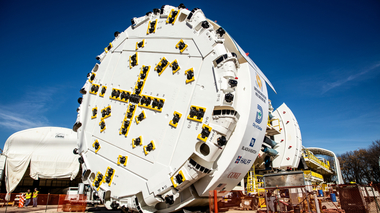

To gouge out a tunnel with a world record-breaking diameter of more than 14 m – almost twice the diameter of the Euro Channel Tunnels – Ontario Power Generation needed the most advanced tunnel boring machine available. Austrian firm Strabag SE was hired as the design-build contractor and engineering firm Hatch Mott MacDonald Ltd. provided technical and management oversight.

Using parts shipped from around the globe, Strabag and Robbins, an Ohio-based manufacturer of underground construction machinery, built the world’s largest hard-rock tunnel boring machine. Fully assembled, the 4,000-tonne Big Becky – nicknamed by local school children – measured an impressive 150 m long and 14.4 m high – as tall as a four-storey building. To bore its way from the tunnel’s outlet to the intake at the other end, Big Becky was required to grind and munch its way through more than 1.7 million m3 of rock – enough to fill 100,000 dump trucks. Its 85 disk cutters could cut through about 2.5 m of hard rock per hour.

Construction at the outlet began in September 2005. Six months later, Strabag and its subcontractors started working at the intake, located near International Niagara Control Works, part of the system that controls the volume and flow of water over the Horseshoe and American Falls. Then Big Becky started drilling in September 2006.

The project has provided employment and about $1 billion in economic benefits to the Niagara region. At its peak almost 600 people were employed directly on the project. But as might be expected with an undertaking of this magnitude and complexity, there have been a number of challenges along the way.

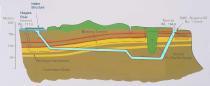

Machine and crew faced difficult ground conditions, characterized by high in situ pressure, swelling rock, aggressive groundwater, and steep grades at either end of the tunnel. To address overbreak problems with the Queenston Shale rock formation surrounding sections of the tunnel, OPG realigned part of the tunnel and reduced its length by about 200 m.

After Big Becky pushed through to the intake end of the tunnel in May 2011, the crew moved on to Phase II of the project, which involved installation of a waterproof membrane and about 400,000 m3 of cast-in-place concrete lining.

Some people have wondered if the Niagara Tunnel might affect the water flow over the Horseshoe Falls. The 1950 Niagara River Water Diversion Treaty stipulates the minimum flow over the falls for scenic purposes therefore the scenic flow commitment will not change. However, when the tunnel is in service, power flow available to Canada will exceed OPG’s diversion capability less than 15 % of the time.

With the Niagara Tunnel complete, Ontario has moved one step closer to its goal of generating 9,000 MW of hydro power by 2018 and creating a diverse and reliable supply of clean, renewable energy for Ontarians.