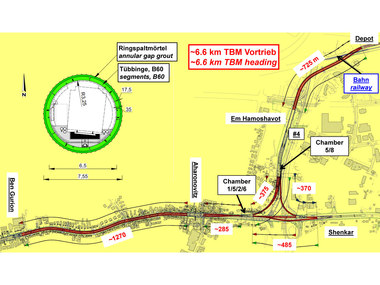

Red Line Tel Aviv: Planning and Constructing the

TBM Tunnels of the Eastern Section (Part 2)

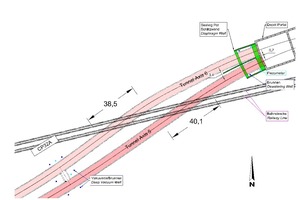

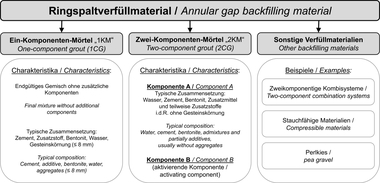

The Red Line is the first line of the Tel Aviv urban railway. 2 x 2.7 km tunnels were driven using two EPB tunnel boring machines from Herrenknecht for the eastern section of the Red Line. It is being built by a consortium comprising the Israeli construction company Danya Cebus and the Chinese contractor CCECC. The WBI GmbH undertook the detailed design and accompanied construction activities on behalf of the joint venture. This report follows up on the previous one that was published in tunnel 4/2019. It deals with the appropriate mix composition of the annular gap grout and the driving activities in the tunnel sections in clay and Kurkar.

6 Annular Gap Grout

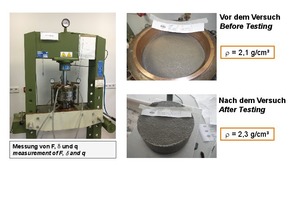

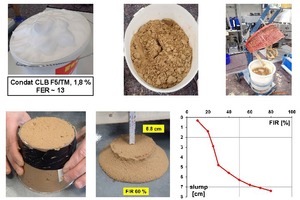

A cement-based mortar was used for grouting the annular gap for tunnelling the eastern section of the Tel Aviv Red Line [2]. The mixes applied are presented in Table 1. The grout properties were tested in the lab at the WBI-Center.

The fresh mortar has a density of 2.1 g/cm³. Workability was proven by means of slump tests, in which horizontal slumps of roughly 50 to 60 cm could be achieved on up to 6 h old samples.

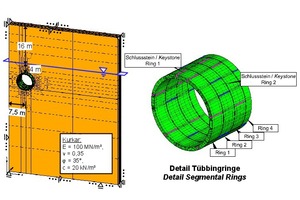

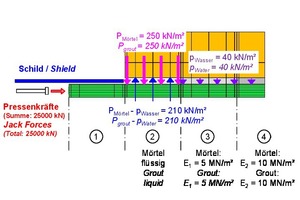

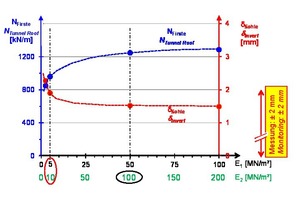

The deformability of the annular gap mortar in its fresh state is of decisive importance for dimensioning the segmental lining. Therefore, oedometer tests were...