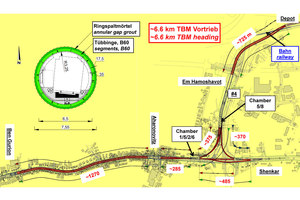

Requirements for Annular Gap Mortar for TBM Driven Tunnels With Single Segmental Lining

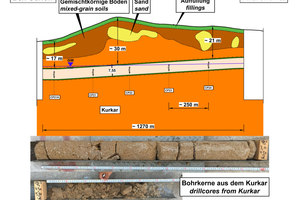

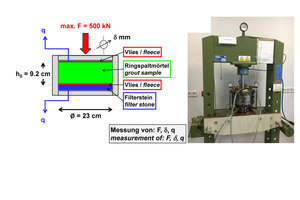

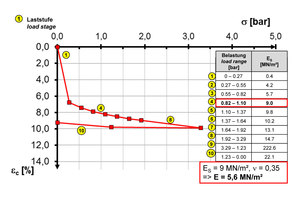

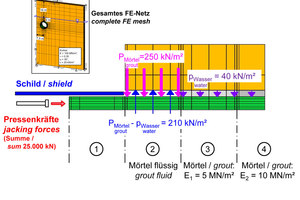

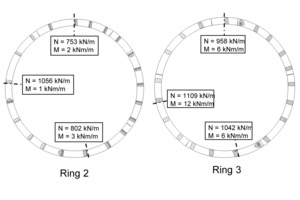

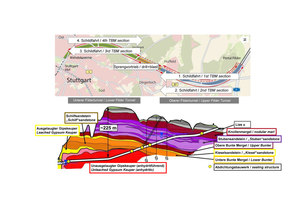

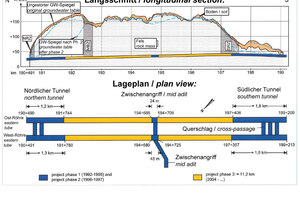

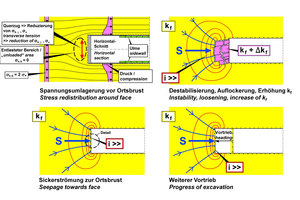

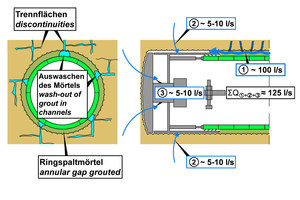

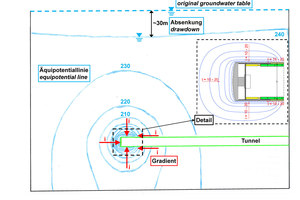

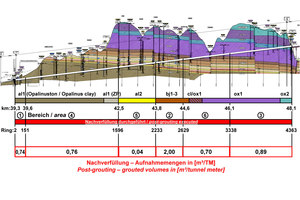

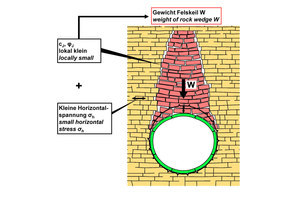

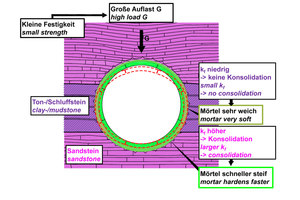

The complete backfilling of the annular gap between the excavation contour and the outer contour of the segmental ring with a suitable material is an essential element for supporting the rock mass, for ensuring the load-bearing capacity of the segmental ring and thus also the stability of the tunnel, as well as for avoiding water flow in longitudinal direction along the tunnel. In this article, essential aspects of annular gap grouting are explained on the basis of exemplary projects. For the selection of the material as well as the method of backfilling, the various influencing factors such as subsoil, TBM, segment lining, construction aspects, durability of the material as well as any special conditions must be considered in a realistic manner. Three-dimensional stability and seepage flow analyses are suitable for this purpose, if they take into account the areas of the temporary face, the shield and the segmental ring as well as the surrounding rock mass. Due to the complexity as well as the importance of this issue, investigations and selection of a suitable annular gap filling material should already be carried out in the planning phase.

1 Introduction

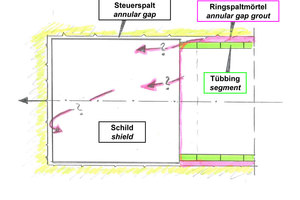

In TBM driven tunnels, the segmental lining is installed inside the shield. With the aid of the jacks, the finalized segmental ring is pressed against the already installed rings and held in place via vertical frictional forces. In this state, driving continues, the segmental ring leaves the shield, and an annular gap in the order of one to three decimeters is created between the excavation contour and the outer contour of the segmental ring. This annular gap must be backfilled with a suitable material to ensure an adequate support of the rock mass, the load-bearing capacity of...