Site Supervision and Quality Assurance of a Project with several TBM Drives

All those involved in building are aware of the significance of intelligent site supervision and quality assurance. The following report presents its successful transposition taking the example of the Brightwater Treatment System in Seattle/USA.

The Brightwater Project in Seattle, King County, is numbered among the largest building projects in the USA, which are part of a national project for the comprehensive renovation and expansion of the public wastewater treatment system.

Through this project the client is increasing the current treatment capacity in the northern suburbs of the City of Seattle. All in all the Brightwater Treat-ment System foresees the building of a new clarification plant near the town of Bothell in the east and new transport pipelines. In the west the project ends with an underwater diffuser in the Puget Sound, an arm of the Pacific Ocean. The investment value of the total project is worth some 1.8 billion US$ (Fig. 1).

The transport lines are to be housed in a tunnel with an overall length of roughly 21 km. Depending on the project section the tunnel’s external diameter amounts to between 4 and 5 m. Subsequently the transport lines will be installed and the intermediate areas backfilled.

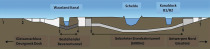

The project geology mainly consists of different boulder marls with in some cases extremely high abrasiveness influenced by the ice age – with water pressures of up to 7.5 bar as a result of the high overburden (Fig. 2).

Owing to the length of the construction scheme the tunnel was split up into 4 drives and 3 contract sections were commissioned. All drives are between 3.5 and 6.4 km in length without intermediate shafts. The contractors responsible for the West and East Contracts have chosen EPB-TBMs. Two slurry shields were requested by the client for the Central Contract on account of the high water pressures (Fig. 3).

Driving operations for the East Contract were successfully concluded at the end of 2008, whereas the other 3 TBMs all still have to tackle more than the half of their driving sections.

Jacobs Engineering Inc. commissioned by the client to undertake the supervision of construction, sought a device for scanning the driving operations and for controlling the quality of the tunnel, which had to fulfil the following requirements:

– complete data storage of the driving and machine parameters in real time on a data server

– flexible data visualisation of the collected data in freely selectable formats

– one system for all drives, regardless of the TBM manufacturer

– access and working with the programme from external offices via the Internet as well

– data storage and readiness also after completion of the drives

– aids for evaluating the data and to trace the quality management via additional functions

The client and the construction supervision jointly decided in favour of the software TPC (Tunnelling Process Control) devised by Babendererde Engineers.

Data Processing and Data Bank Administration for the TBMs

As a result of the high demands placed by the 4 drives that have to be monitored at the same time with different tunnelling systems and the major distances between the starting shafts and the main office at local level, an infrastructure for data collection was evolved jointly.

The aim was to set up a separate, safe and as far as possible secure network, which collates all driving data at a central point and makes a standard data structure available to the user for the further evaluation of all the drives. Fig. 4 displays the developed hardware structure with its main components.

The hardware structure comprises 1 main server in the main office and 2 ancillary servers on the East and West Contract sites, which are linked with each other via a coded VPN connection (Virtual Private Network). The main server at the same time provides the gateway for an open number of external users. Access to the software is arrived at via a standard PC with a coded internet access.

The 2 secondary servers are linked with the tunnel via a fibre glass line. Apart from direct transference of data to the main server, the secondary servers provide redundant storage and replication of tunnelling data. For the 2 slurry TBMs for the Central Contract the data are collected by the contractor and set on a FTP page at regular intervals (every hour). The main server takes over the newly available data from the FTP page and processes them further.

Software

The TPC software was implemented in such a way that it processes all types of TBM and manufacturers. Given an average number of 130 sensors per drive and a 10 sec record-ing interval this results in an annual data amount of 1,639,872,000 entries. This huge quantity of tunnelling data, which are stored multidimensionally in a SQL data bank, can be visualised whenever required with constantly remaining inquiry times. In addition the data bank is devised in such a way that data manipulations can be excluded.

The regular inquiry and report components were tailor-made to suit requirements at the start of the project in order to ensure that the site supervision was relieved as far as possible as far as this was concerned. Standard reports are automatically produced, filed and distributed independently by e-mail. The system also reads manually produced excel tables, as for example settlement measurements and the loads carried by trains automatically into the data banks.

Corresponding user profiles with different access authorisations were set up for every personnel level of the project, which offer special desktops ranging from the site supervisor, the project engineer right up to the project manager and supply different reports and evaluations.

Special Reports

During discussions technical issues relating to the ongoing drive are on the agenda. Towards this end the presentation of the issues also compared with further driving parameters plays a decisive role. The special reports enable the presentation of graphics with free choice of the axes, parameter combinations and the data density. The straight-forward use makes it possible to print or plot even inquiries over a great distance within a matter of minutes (Fig. 5).

Real Time Monitoring with active Limit Value Monitoring

Inspectors both in the tunnel as well as in the office on the surface supervise the drives as well as the quality assurance. In the office real time monitoring with flexible desktops provides support. Every user can create “his own” desktop depending on his position. The nature of the presentation, positions and groupings are adapted in accordance with one’s own requirements. Fig. 6 exemplarily shows a screen shot on the display page of a drive in a real time presentation.

The displays are updated at 10 sec intervals with the currently available data. In this connection, all incoming data are first checked to establish their consistency and plausibility. Selected values are at the same time compared with the limit values defined at the start of the project. If an active limit value is exceeded the responsible persons are informed by e-mail or SMS. An automatic cancellation report of a limit value being previously exceeded also follows.

Shift Reports and Evaluation

The recording of the driving times and the assessment of the standstills represents one of the main tasks not simply for the drives for the Brightwater Project. In this way the construction companies as well as the site supervision are provided objective details of the actual drive. The flexible

assessment of the standstills assists all those involved in evaluating priorities as well as in finding out reasons for technical problems. At the same time various tunnelling systems are taken into consideration in this way.

In this project the shift reports are filled in semi-automatically on the basis of the driving parameters received. At the end of his shift the inspector divides the recorded standstills into the given category and is able to provide further observations via the keyboard. The site supervision and the construction firm can also allot proposals for establishing which of the individual parties was responsible for an incident. In this way an assessment of the standstills can be very effectively reproduced in retrospect. Fig. 7 displays such an input mask for the shift report during a delay classification.

The data from the shift report in Seattle serve the site supervision as a data base for evaluation in the analysis model. The individual driving activities can be presented on the basis of classification. The site supervision presents these analyses for each tunnel, which are filtered in keeping with critical, i.e. waiting periods holding up the drive and non-critical ones.

Quality Management and Documentation

The securing of the quality of execution and the documentation of the structure are the original tasks of the site supervision and this also applies in Seattle. Toward this end the extensive tunnel length and the various contractual conditions represent an above-average challenge to the client’s organisation. However, the construction firms too wish to be able to undertake consistent tracking of faults which is nevertheless easy to operate. Only in this way is it possible to confine the amount of personnel required within limits.

In this connection the site supervision uses 2 tools, which simplify both documenting the structure and tracing faults. Ring reports sum up the important TBM parameters, the installed segmental rings and backfilling the annular gap. This report is automatically produced and distributed for each ring. In addition the inspector can insert damage caused to the segments in the QM/QC module. The position and nature of the damage is entered per mouse click. Further progress in repairing each individual case of damage is thoroughly documented by means of text and photos. The repair is then contractually accepted by the site supervision on a print-out form (Fig. 8).

Project Progress – further Modules

Comparison of the actual project progress with the planned assumptions is always exciting for all those involved whether there is an early indication that the contract can be executed without any problem or whether tense discussion relating to construction progress must be reckoned with.

Towards this end the software presents a graphic comparison, which can be minimised as desired ranging from the total project to the working shifts. A graphic projection based on the actual average progress can also be displayed.

In future a projection will also be applied for the cost module, with the actual costs being compared with the planned expenditure. This module is of particular interest for contractors (Fig. 9).

Summary

The Brightwater Project is right in the middle of being executed. Since October 2007 TBMs have been operational there. Currently roughly 8.5 km of tunnel has been driven. The software has emerged to be a very effective tool for the site supervision.

Furthermore unscheduled knock-on effects have resulted. For public project progress presentations, which are treated very seriously in the USA, the real time presentation is often referred to. It creates a certain “wow” factor among the public. This presentation also convinces local residents that any disturbance they might perceive cannot originate from the TBMs when it comes to complaints about soil vibrations.

In the long term data storage leads to advantages in tunnelling as a whole. With the help of data processing systems and corresponding evaluations it has first become possible to process historic data within a reasonable cost framework and to interpret them for new projects. As a result more precise predictions will be arrived at in the course of the years to come than were possible by simply trying to replicate them off the cuff. In this way tunnelling methods can be optimised even further.