Wehrhahn Line, Düsseldorf: Opening of the inner-city Tunnel Project

The ceremonial opening of the Wehrhahn Line in Düsseldorf, the capital of North Rhine-Westphalia, Germany, took place on 20 February 2016. Surrounded by businesses and shopping streets, the tunnelling project to extend the Düsseldorf Stadtbahn was constructed between 2007 and 2015 through the heart of the city. Particularly in the inner city, the responsible engineers had a number of challenges to overcome, for example the restricted space available, the requirement to minimise nuisance to the shopping area and tunnelling beneath a 100-year old department store. The company Zetcon Ingenieure was responsible for the complete project supervision and site supervision for structural and fitting out work on the eight-year project as part of the engineering joint venture „ARGE BÜ/OÜ Wehrhahn-Linie“. This was preceded by a European tendering process. The total investment in the project is about 843 million euros.

Construction Start 2007

Traffic jams in the city centre of Düsseldorf lead to considerable obstruction of the traffic flow, so the new underground line is intended to considerably reduce traffic in Düsseldorf. The completion of the new line will also cut journey times and link the east and west parts of the city better to the inner city. With six underground and two overground stations, the Wehrhahn Line with a total length of 3.4 km connects two important S-Bahn rapid transit stations, the “Am Wehrhahn” and Schadowstraße shopping streets, the Königsallee boulevard and the department store “Kaufhof an der Kö”. Most of the new Heinrich-Heine-Allee underground station is located directly beneath the foundations of the department store building. The Heinrich-Heine Allee in the old city centre is also the node where all the existing underground lines interconnect.

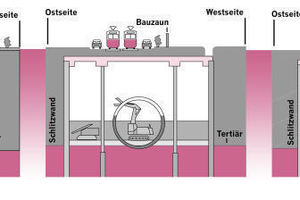

The first section of the Wehrhahn Line was constructed as long ago as 1983, already with the intention of extending it underground. In 2007, the extension became reality with the start of further tunnelling works. The Wehrhahn Line was divided into two construction contracts: contract 1 with five stations in top-down construction and two ramp structures in cut-and-cover, and contract 2 with the section beneath the historic department store and the link to the existing Heinrich-Heine-Allee station.

Top-down Construction

The main aim of the entire construction design was to minimise nuisance to the inner-city inhabitants and businesses and reduce encroachment on the surface as far as possible. All the underground stations were therefore built top-down, allowing traffic to continue with little hindrance. The construction excavations were enclosed with watertight diaphragm walls in accordance with the requirements of a demanding support concept. First a diaphragm wall up to 42 m deep was constructed on one side of the road and then topped with a concrete slab. This forms the roof of the new station. In the next construction phase, the same followed on the other side of the road. The advantage of the construction method is that traffic can still run on one side of the road and life in the inner city is only disturbed to a certain degree. Only after the completion of the ground slab could the underground excavation and structural works began.

Shield TBM with a Diameter of 9.50 m

The tunnel was completely excavated underground, with tunnelling works being divided into two drives, south and east, each with a total length of 2.3 km. Since the running tunnels were below the water table, a machine with slurry support to the face was used and a single-pass lining of eight segments per ring with a segment thickness of 45 cm. In the eight months of each drive, the Herrenknecht tunnel boring machine (TBM) with a diameter of 9.50 m excavated about 450 000 m3 of mixed sand and gravel. This produced two tunnels with internal diameters of about 8.4 m, with the machine advancing at about 10–15 m per day. In order to secure the existing buildings and reduce settlement, screen walls were installed along entire buildings in some places. In addition, further measures were also provided to protect existing buildings, such as compensation grouting.

Special Ground Freezing Technology

under the historical “Kaufhof an der Kö”

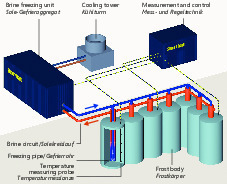

One particular challenge in the whole project was the ground freezing under the 100-year old department store on the popular shopping street Kö. Due to the listed Art Nouveau facade, boring under the department store was not possible, since ground vibration could have affected its stability. The tunnel beneath the Düsseldorf shopping landmark was thus mined under the protection of ground freezing – a process, which has only been applied on a few tunnel projects so far, to prevent structural damage to a building above, and demands particular expertise and experience. A frozen body was created to seal the building against groundwater and at the same time stabilise the soil in order to protect the department store against any vibration. Freezing boreholes were therefore drilled between the diaphragm wall-supported excavations of the starting and target shafts, with a 30 per cent calcium chloride solution cooled to - 35 °C being pumped through the altogether 120 freezing pipes each with a length of 75 m, with a freezing plant power of 1200 kW. This created a surrounding frozen body with a thickness of about 2.5 m. Considering this thickness and the maintenance of the frozen body for two years, only brine freezing was practical.

Sensors to

measure the Density

of the Frozen Body

About 500 temperature sensors were used to monitor the ice layer, measuring the density and extent of the frozen body every five minutes. Another 105 measurement points were mounted on the facade of the department store building. This meant that the site supervision had everything under control and could check the figures round the clock. It took about 60 days until the entire ground was frozen. Only after the completion of freezing could excavation start by mining from the starting shaft. A central shaft and two side tunnels were excavated and supported in several phases with shotcrete. In order to keep settlement due to construction works as small as possible, the participating contractors drilled 72 m long horizontal guided holes for compensation grouting under the foundation of the department store, which could be used to systematically compensate any movements of the building.

Ceremonial Opening of the new Line

After tunnelling works had been completed the fitting out of the underground stations proceeded. The Rheinbahn, operator of public transport in Düsseldorf, has been undertaking test runs on the new Wehrhahn Line since April 2015. The ceremonial opening was on 20 February 2016. More than 50 000 passengers are expected to be using the new subway line every day.