Test Methods for the Acquisition of Additional Material Properties of Two-Component Mortars

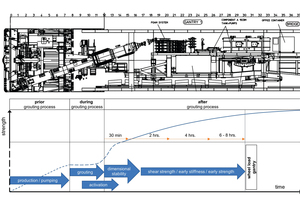

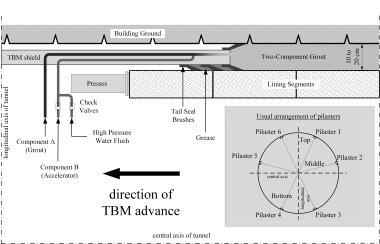

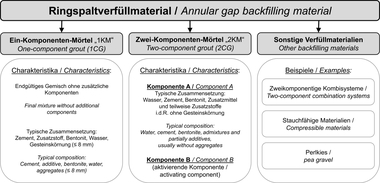

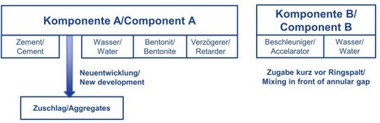

The utilization of two-component mortars as a filling material for annular gaps in mechanized tunnel construction is gaining prominence both internationally and nationally. The ready-mix component (A) comprises a mixture of cement, (additives), bentonite, water, and includes a combination of a retarder and potentially a plasticizer. Component B, an activator typically made of water glass, is added to component A during grouting, promoting both consolidation and the progressive enhancement of strength and stiffness.

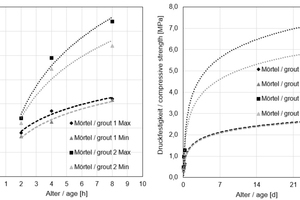

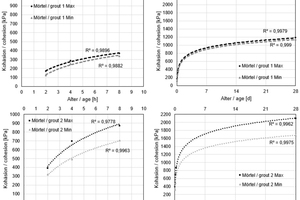

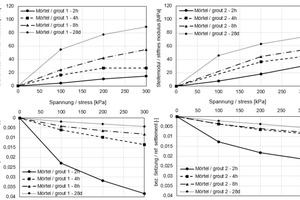

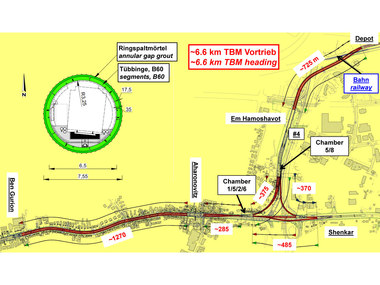

The tunnel boring technique poses significant demands on the stability of the tunnel tube, which depends on various factors including the time-dependent strength and stiffness development of the annular gap filling material. To conduct a finite element analysis of the material behavior, reliable material parameters such as modulus of elasticity or stiffness modulus are often lacking, requiring assumptions to be made. These assumptions are typically based on the relationships between material parameters in concrete technology, which can be inaccurate for annular gap filling materials as their...