Boßler Tunnel: Influence of Rock Mechanics on the Tunneling Concept – Tendering and Execution

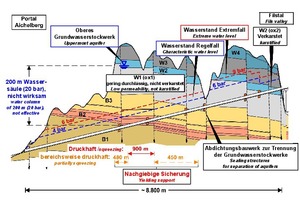

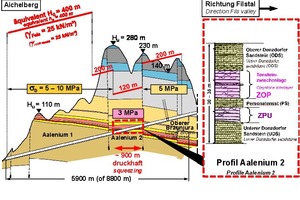

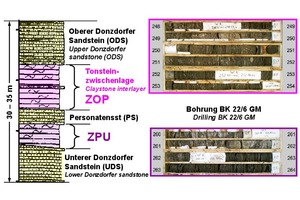

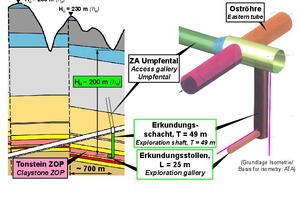

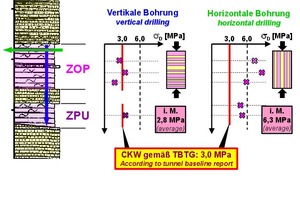

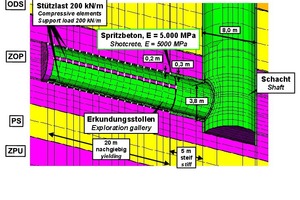

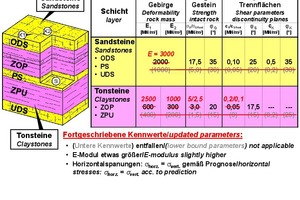

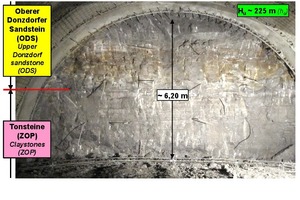

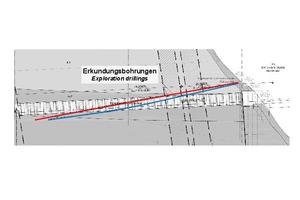

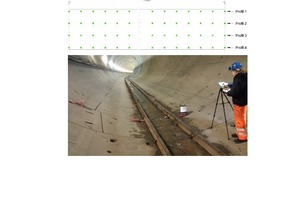

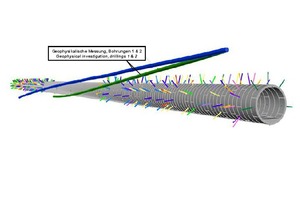

Using the example of the Boßler Tunnel, the importance of careful rock mechanical investigations for the excavation concept of a tunnel is shown. The preliminary exploration revealed that squeezing rock conditions were to be expected in the middle section of the tunnel. In another tunnel section, karstification had to be expected. Towards this background, the tunnel was tendered for construction with conventional means (“shotcrete method”). Along the first 2.8 km, the use of a TBM was permitted. By driving an exploration shaft and gallery combined with accompanying rock mechanical investigations and numerical calculations, it was possible to create the basis for allowing for a TBM-excavation in the entire formation of the Brown Jurassic. In addition, the program for karst exploration was adapted to the requirements of a TBM heading.

1 Introduction

In the following, the importance of careful rock mechanical investigations for the excavation concept of a tunnel will be shown using the example of the Boßler Tunnel. On the basis of the results, it was possible to excavate a tunnel with a tunnel boring machine over its entire length, though the tender had limited TBM excavation to a minor length and predominantly foreseen conventional excavation.

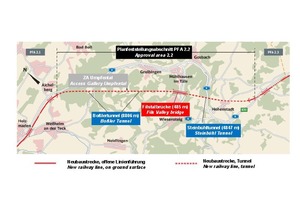

2 Project

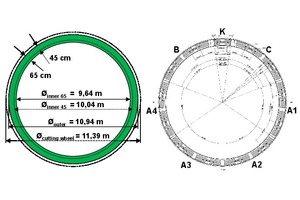

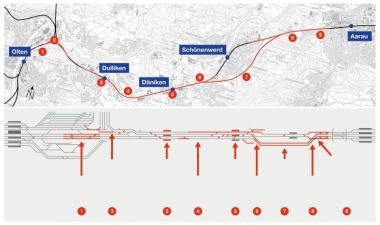

The 8.8 km long Boßler Tunnel consists of two tubes arranged at a distance of 30 m with circular cross sections and an inner diameter of approx. 10 m. The tunnel forms part of...