Tunnelling and Mining: Suppliers at the bauma 2013 in Munich

This bauma was the biggest ever – featuring 530,000 visitors from more than 200 countries and over 3,400 exhibitors from 57 nations. The exhibition space was also extended to 570,000 m². These figures were cited by the organiser, the Messe München GmbH, in their press releases partly before and after the major event. Characteristic for the mining machinery exhibition segment is that so far it has managed to escape the negative trend experienced by the construction machinery branch.

Since 2007 turnover for the German machine manufacturers belonging to the VDMA’s mining machinery sector, to which many makers of tunnelling machines belong, has increased by an average of 13 % per annum.

Dr. Paul Rheinländer, chairman of the specialist association, showed himself to be highly pleased by this result even prior to the bauma: “This means we are numbered among the few branches in Germany, which have grown throughout the entire crisis”.

The awarding of the bauma Innovation Prize can be described as the event at the fair. Altogether prizes for outstanding innovations were presented in 6 categories at this year’s bauma

.

Pipe Express: Innovation for Laying Pipelines

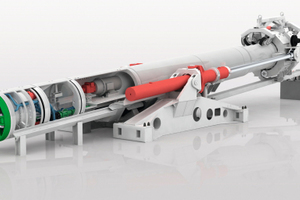

In the “Machine” category, the Herrenknecht Company’s “Pipe Express” was awarded the bauma Innovation Prize 2013 (Fig. 1). Pipe Express is a new mechanized method for the near-surface installation of pipelines more than 1,000 m in length and with diameters of 800 to 1,500 mm using the semi-trenchless construction method. A TBM loosens the soil which is then directly conveyed above ground using an accompanying milling unit. Simultaneously the pipeline is installed underground. As earthwork is reduced to a minimum using this construction method and no groundwater lowering along the route is necessary, Pipe Express has only very little impact on the environment.

The modular design of the entire system includes a TBM that works underground and a milling unit as a vertical connection between the TBM and the terrain surface. An operator vehicle accompanies the installation system, providing the entire logistics: the operator’s control stand, the power unit room, a high-capacity pump and a storage container for bentonite. With the integrated crane system, assembly and dismantling work can be completed in a very short period of time. The thrust force for the excavation unit and the pipeline is provided by a Herrenknecht Pipe Thruster from the launch position. As the operation vehicle is remote controlled, it requires minimum manpower and a high degree of work safety is ensured.

Dr.-Ing. E.h. Martin Herren-knecht, the chairman of the Herrenknecht board commented that “ bauma 2013 turned out to be nothing but sunshine for Herrenknecht. The public was first class and highly global. We were able to display our widespread portfolio and our top innovations for Tunnelling and Mining in an appropriate manner”.

AutoPilot Field Rover supports Slip Forms

In the “Components” category the Innovation Prize was presented to Wirtgen’s AutoPilot Field Rover. This innovation enables slip forms to be produced with far more ease.

So far stringlines have had to be provided for producing concrete profiles – an expensive and time-consuming business. They got in the way during the installation process and subsequently had to be removed. This is no longer necessary for the Wirtgen AutoPilot Field Rover has heralded in a new era.

The GPS controls the steering and pitch of the slip form paver by fully automatic means – without having to set up a digital ground model. Wirtgen offers this new technology for the SP 15 and SP 15i as well as SP 25 and SP 25i slip form pavers including the possibility to retrofit existing machines. As is customary when surveying, a plumb rod is applied for the route. Here individual measurement points are defined, on the basis of which the Field Rover’s software calculates the course of the reference line – essentially the virtual stringline.

High-Performance Surface Miner

Wirtgen produces and markets a further multi-talent, which was also shown at the bauma: the SM 2200 – its smallest Surface Miner with 2.20 m cutting width and a cutting depth of up to 30 cm – as standard.

This machine’s modular design is highly advantageous in practice: the machine can function as a classical Surface Miner in mining to extract coal and other useful minerals up to a uni-axial compressive strength of 50 MPa as well as a high-performance milling machine after straightforward conversion. This guarantees that the machine is fully utilized. The dual operation concept has turned the machine into the most successful special tool on the Surface Miner segment. The engineering techno-

logy is constantly being further developed.

New highlights were presented at the bauma, including an almost 2 t heavy steel element to strengthen the structure, which makes the machine even more robust when tackling hard rock, increases its service life and reduces vibrations. This signifies that the SM 2200 is even better suited to operate on uneven terrain with the driver profiting from more operating comfort.

Improved shock absorption in the cab at the same time caters for better thermal protection – so that the driver feels even more at home given tough operating conditions for the 2200 SM in extreme temperatures.

A new scraper has been developed for the Windrow Mode: the material is optimally discharged from the unit, thus increasing performance and simultaneously reducing wear on the unit, milling drum and cutters. The scraper produces a level surface for the rear crawlers so that they are better protected against wear.

The versatile Surface Miner with an engine rating of 671 kW / 912 HP has a standard 2.20 m milling drum, but can also be equipped with a 3.80 m unit for cutting softer rock which boosts its milling performance by at least 40 %. This applies particularly when cutting rock with an unconfined compressive strength of less than 30 MPa. The milling drum with a working width of 3.80 m is most effective for mining coal/lignite, soft limestone and soft marl, phosphate and gypsum. The immense potential of the 2200 SM is optimally exploited with the wider milling drum while cutting operating costs and the consumption of fuel and cutters at the same time.

The machine consists of a crawler assembly and a mechanically driven cutting drum. As an alternative it is available for front loading with height-adjustable and swivelling discharge belt and for the Windrow Mode.

Mobile Tunnel Miner: Undercutting hard Rock

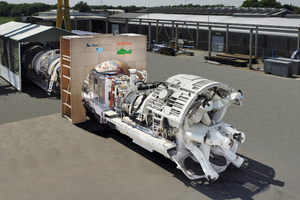

No prize but still nominated: a further-developed prototype of Aker Wirth’s Mobile Tunnel Miner (MTM) (Fig. 2), whose initial trial run certainly impressed even in the animation. The machine has been operating since the start of April at the copper/gold mine run by Rio Tinto in New South Wales, Australia to drive a 1.6 km long tunnel. Undercutting technology differs from tunnelling by full-face excavating machines with the disc cutters – in similar fashion to a glass cutter – not being pressed at right angles to the rock being removed in order to create a compressive force but slightly inclined so that they “undercut” the rock and blast it in the form of palm-sized chunks. In other words the disc cutters only operate during the short phase of cutting against the compressive strength of the rock and subsequently against the substantially lower tensile strength. The required forces are correspondingly smaller. The amount of energy needed for excavating the rock during the undercutting process is roughly half as much as in the case of conventional tunnelling.

The self-propelled machine moves on a crawler assembly and advancing gear and removes the rock using 6 powerful, hydraulically driven arms fitted with disc cutters. The muck is transported by a loading apron with loading discs to the rear of the machine by a chain conveyor where it is loaded.

Constricted Spaces – no Problem for dhms

dh mining systems were strongly represented at the bauma. A dh R74 roadheader, a dh DT1 jumbo, a side-tipping loader dh L1200 and – as highlight – the EQ200 compact excavator as robust, universal machine for confined underground spaces and shafts. This is an extremely compact piece of equipment mounted on a crawler assembly, which offers advantages under given restricted space conditions. Apart from its space-saving method of construction, it is particularly distinguished by its wide range of attachments, which can be changed speedily thanks to a quick-coupling system.

Sandvik concentrates on conventional Excavation

The Sandvik subsidiary Construction presented a wide range of different methods for tunnelling and mining at the bauma – from drill+blast by way of mechanised cutting right up to crushing and reducing rock with the corresponding machines. The selection shown included jumbos for tunnelling, anchor placing installations, drilling and cutting tools as well as anchors, hydraulic crushers, loading and transport installations. Three new small hydraulic hammers from Sandvik’s Rammer range as well as 3 models, specially devised for ripping, which also possess air, lubricant and water feeds for automatic lubrication and the efficient suppression of dust.

The Paus Range minimises Exhaust Gas

Once again, Hermann Paus Maschinenfabrik GmbH showcased its extensive product range at bauma, a range including tunnelling and mining vehicles, hoisting technology, construction machinery and industrial vehicles. The loaders displayed by Paus at the bauma 2013 – including articulated, swivelling and telescopic loaders – were provided with the latest generation of DEUTZ engines in accordance with EU Guideline Stage III B.

Cooperation – not only at the Stands

In conclusion a visit to the many joint stands of companies involved in the supply and service branches, authorities, organisations and federations was certainly worthwhile for it reflected a visible indication of cooperation on international markets.

Thanks to rather than in spite of its size, the 2013 bauma in general – and the Mining and Tunnelling Segment in particular – provided the international public a unique chance to become acquainted with the wide selection of machinery and equipment as well as new methods. In this connection, there was always the opportunity to engage in discussions, some of which will undoubtedly have led to orders.