High Performance Steel Fibres Offer New Possibilities for Permanent Sprayed Concrete Lining

Modern sprayed concrete technology and the use of steel fibers have made permanent, single-shell linings for tunnel construction possible. Until now, mainly temporary layers of sprayed concrete were used for stability, followed by a permanent concrete lining. But now such an inner lining can also be produced with high-quality, steel fiber-reinforced sprayed concrete. This saves costs and reduces construction time, especially for complex surfaces. This economical system provides durable, waterproof and structurally solid linings comparable to cast-in-place concrete.

Sprayed concrete technology has dramatically improved in the use of advanced admixtures, robotic spraying equipment and application methods to produce durable and high performance concrete

Sprayed concrete technology has dramatically improved in the use of advanced admixtures, robotic spraying equipment and application methods to produce durable and high performance concrete

Credit/Quelle: Bekaert

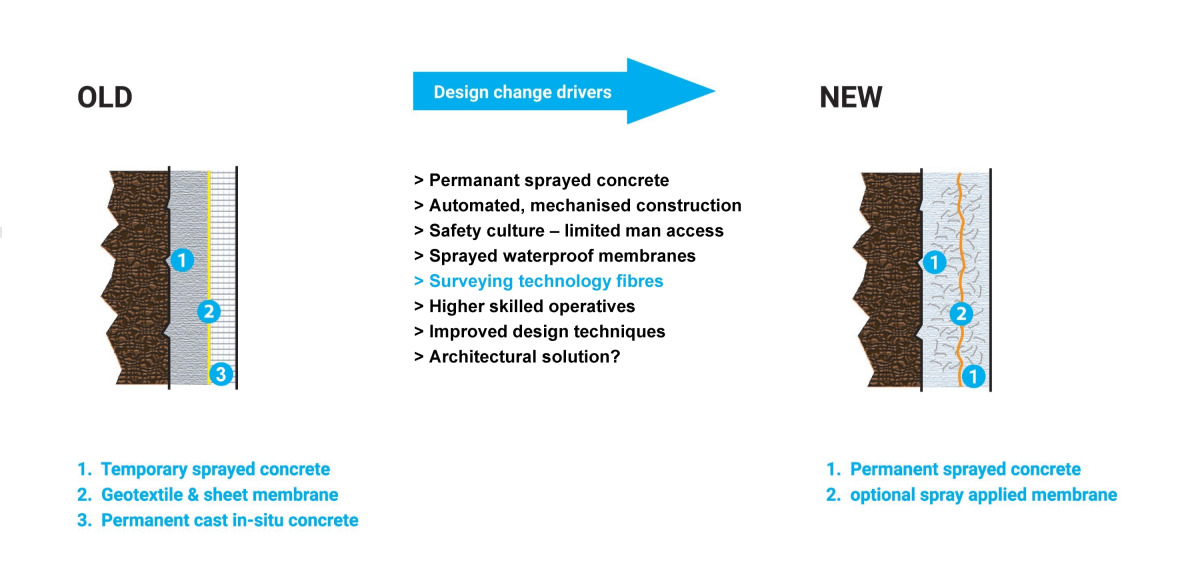

Conventionally, tunnels constructed using sprayed concrete have been based on a temporary sprayed concrete lining to stabilize the opening after excavation and to contain short to medium-term loads. When this lining has fully stabilized, a permanent cast in-place concrete lining is installed to contain long-term loads and provide durability. A waterproof membrane between the temporary and permanent lining ensures water tightness and is called the double shell method.

Sprayed concrete technology has dramatically improved in the use of advanced admixtures, robotic spraying equipment and application methods to produce durable and high performance concrete. These improvement in sprayed concretequality made it possible to use permanent steel fibre reinforced sprayed concrete instead of conventional in-situ concrete within the temporary sprayed concrete linings, lowering costs and significantly reducing the construction time, particularly in sections of complex geometry such as step plate junctions.

Currently, modern sprayed concrete technology equips the tunnelling industry with a more economic tunnel lining system in the form of a singleshell of permanent sprayed concrete. This technology provides a structural lining that is durable, watertight, and the surface can be finished to a degree that is similar to cast concrete.

Concrete technology equips the tunnelling industry with a more economic tunnel lining system in the form of a single shell of permanent sprayed concrete

Concrete technology equips the tunnelling industry with a more economic tunnel lining system in the form of a single shell of permanent sprayed concrete

Credit/Quelle: Bekaert

Advantages of Fibre Reinforced Concrete

Permanent sprayed concrete is a proven technology that has been used for many applications in underground worksthroughout the world. The ITA WG12 report in 2001 listed more than 150 permanent sprayed concrete lining (PSCL) projectsin 11 countries. The use of steel

fibre reinforced sprayed concrete allows to reduce or eliminate the traditional reinforcement in permanent lining. Over the last few years, the use of this technology has increased. One of the aspect that are boosting the use of fibre reinforced concrete (FRC) in permanent lining is the introduction of guidelines for the design of FRC. In 2013, the fib – Fédération internationale du béton – presented the Model Code 2010 in which a specific part related to FRC is inserted. This document has sparked great interest in the tunnelling community and several documents consider Model Code 2010 as a reference.

Furthermore, the emissions during construction by conventional methods are higher than the emissions of TBM tunnelling. Results showed that, in the case of conventional tunnelling (drill and blast), materials are responsible for approximately 60 to 80% of the total impacts depending on the impact indicator [4]. Changing temporary shotcrete lining and permanent cast-in-place lining to permanent shotcrete lining and improving the mix design could lead to a huge CO2 saving up to 75%.

Changing temporary shotcrete lining and permanent cast-in-place lining to permanent shotcrete lining and improving the mix design could lead to a huge CO2 saving up to 75%

Changing temporary shotcrete lining and permanent cast-in-place lining to permanent shotcrete lining and improving the mix design could lead to a huge CO2 saving up to 75%

Credit/Quelle: Bekaert

The excessive structural design for cast-in-place concrete or other lining structures used in the current practice have a significant impact on cost, excavated volume of rock mass, construction time and CO2 emissions. The use of steel fibre reinforced concrete provides several advantages, compared with traditional steel mesh or steel bar reinforcement:

It can facilitate remote working from the face, and may remove the need for traditional reinforcement, to enhance the safety of the workers

It provides cracking control and a small enhancement of the concrete’s tensile properties

It is less prone to carbonation and chloride attack

Reduction of cost

Less material usage (through minimising the amount of steel and concrete cover required)

Two general systems can be considered to create a single shell tunnel. The first is a true one step application method for small diameter tunnels, or tunnels founded in stable, dry ground conditions. The second approach is a two-layer application process where the first layer achieves tunnel stability and the second layer (acting monolithically with the first), is installed by spraying, and enhances durability and water tightness.

In all cases, the emphasis should be on buildability, where simplicity is the key to success, particularly with a method depending on construction team performance. The advantages related to the adoption of steel fibre reinforced concrete use should be evaluated according to the project characteristics. For a sustainable use of structural concrete, environmental and mechanical performances of concrete structures must have the same importance. This is the reason a number of publications and research projects are dealing with the better use of permanent sprayed concrete lining.

Recent Publications on Permanent Sprayed Concrete Lining

In 2020, the ITA report 24 “Permanent Sprayed Concrete Linings” was published [2]. The main objective of this guideline is to give infrastructure owners and their advisors the confidence to incorporate permanent sprayed concrete lining in their underground space design

A joint AFTES-ASQUAPRO group has developed recommendations for the permanent application of wet sprayed concrete in underground structures. The document of about one hundred pages provides general information and outlines the principles on which it is based. The main objective of the recommendations is to provide assistance for the drafting of technical specifications in procurement contracts. The proposed clauses are intended to be used in tender documents drawn up by the project manager. Some of them can be copied identically.

This document is an aid for the design, contracting and construction of tunnels supported and lined with fibre reinforced sprayed concrete combined with additional metal reinforcements (bolts, steel arches, mesh…), drainage and a waterproofing system. The different types of fibres are discussed, and their field of application is specified. The method of designing the structure by the Model Code 2010 is explained.

This method has been applied in a recent construction project – the Cliets Tunnel, which opened to traffic in June 2021, and whose main characteristics are presented. The technical specification clauses distinguish between the requirements for the concrete before it is sprayed and those for the concrete in place. They cover both the sprayed concrete for preliminary support and the structural sprayed concrete, this latest being calculated to take up the long term loads. The methods for tensile bending tests on notched beams and three point bending test on a sprayed concrete panel with notch are specified , as well as principles for their use, which is essential for structural concrete. Technical requirements are introduced at day 7 in addition to requirements at day 28, in order to improve the detection and treatment of non-conformities, to optimize the reactivity of all stakeholders and to help respect the works schedule.

Many research projects are currently conducted, showing already positive conclusions, like the SUPERCON (“Sprayed Sustainable Permanent Robotized Concrete Tunnel Lining”) in Norway. The final results from this project are yet to come, and hopefully can contribute to more effective tunnelling with less CO2 emissions.

Many research projects are currently conducted, showing already positive conclusions, like the SUPERCON in Norway

Many research projects are currently conducted, showing already positive conclusions, like the SUPERCON in Norway

Credit/Quelle: Bekaert

Permanent Sprayed Concrete Lining for Mumbai Metro

The Sahar Road Crossover Cavern (Mumbai Metro,Line 3) was successfully constructed using a fibre reinforced sprayed concrete permanent secondary lining

The Sahar Road Crossover Cavern (Mumbai Metro,Line 3) was successfully constructed using a fibre reinforced sprayed concrete permanent secondary lining

Credit/Quelle: Bekaert

The Sahar Road Crossover Cavern (SRCC) is a stepped profile cavern on the Mumbai Metro Line 3 project, that was designed and constructed by Bedi Consult [5]. The original design called for a conventionally reinforced, in-situ cast secondary lining. Given the number of geometrical sections and complexity of staging the works, Mumbai Metro Rail Corporation opted to explore sprayed concrete reinforced with steel fibre.

The fibre reinforced sprayed concrete secondary lining was designed and checked for all possible combinations of applied loads and forces in accordance with the Mumbai Metro Rail Corporation‘s Ordinary Design Standard (ODS). This sets out the performance criteria for all civil engineering structures on the project, for the following stages:

Short-term (during construction)

Intermediate (immediately after construction)

Long-term (full design life) loading conditions

Accidental: These include unusual incidents which

may alter loading conditions. For the SRCC, these

included loads arising from train derailment and

fire.

Extreme: Those that occur in service/operation

when groundwater may rise to unusually high

level

The fibre reinforced sprayed concrete was specified to achieve a residual flexural strength class of D3 S2.5 in accordance with BS EN 14487-1. It was tested with the four point bendig test, using beams cut from sprayed panels in accordance with BS EN 14488-3. The mix was dosed with 38 kg/m3 of Dramix 4D fibres,

The crossover cavern was successfully constructed using a FRSC permanent secondary lining. As this was a first in India for any metro project, one of the primary challenges was developing a high quality mix design that would meet all the strength and 120 year durability requirements of the client’s specification, using locally available sand and aggregates, which are inherently variable and considered poor quality for the application of permanent sprayed concrete linings.

Given that it was a first for India, there was some concern whether steel fibre would work for the long term. Bekaert provided a lot of test data, which helped assure the rail corporation and its engineers that this was a tried and tested product. A rigorous campaign of pre-construction and production testing was also implemented to ensure that the permanent sprayed concrete lining met the design specifications throughout construction.

For further projects the new three point bending test method on square panel with notch (EN 14 888-3 method B) will bring even more confidence in material property used for the design. It was suggested that the notched panel test had several advantages, including using a test specimen that better represents the material in the real structure with reduced variability.

WestConnex Project, Sydney

The M4-M5 Link Tunnels in Sydney, Australia, are approximately 7.5 km long and accommodate up to four lanes of traffic in each direction with spans up to 23 m in the main lines and 34 m in transition caverns. It connects the New M4 Tunnels with the M8 Tunnels to form the 33 km long WestConnex motorway, mostly underground. Like many road tunnels in Sydney, these tunnels are designed as drained structures and adopt permanent sprayed concrete linings for a 100-year design life.

M4-M5 Link Tunnels in Sydney, Australia

M4-M5 Link Tunnels in Sydney, Australia

Credit/Quelle: Bekaert

In wet sections of the tunnel, a sprayed waterproofing membrane was adopted where the primary lining is still designed to resist all ground loads and the applicable residual water pressure in the long-term. The secondary lining design is designed without relying on long-term shear transfer by the membrane to resist operational loads and, as a redundancy, also the residual ground water loads.

Sprayed concrete strength: Primary & secondary lining 40 MPa, flexural tensile strength fR1k= 3,5 MPa and fR4k = 3,0 MPa

Lining thickness: Primary lining 110 mm with 35 kg/m3 of steel fibers, secondary lining 125 mm with 35 kg/m³ of steel fibers and 1kg/m³ polypropylene fibers for fire resistance

The use of high-performance end-hooked steel fibres Dramix 4D 65/35BG was effective in achieving the desired high-level performance ground support characteristic design fR4 = 3,0 MPa.

Production testing confirmed performance with only minor outliers, occurring as expected. The high-performance fiber combined with the consideration of compressive membrane action (CMA) allowed for the design of a very thin fibre reinforced permanent sprayed concrete lining

(t = 90 mm) with an assumed unbonded condition with high capacity demonstrated by both numerical modelling and large-scale field tests. The consideration of CMA effects were confirmed by load-bearing capacities that were some 3–6 times greater than those estimated by conventional design methods, based on pure flexural/bending resistance. The outcomes were very positive:

Reduction of sprayed concrete quantity used on the project by 27 000 m3 (15% in thickness) and reinforced steel fibres by 830 t (10%).

Reduction of more than 33 000 t of embodied carbon (CO2e) from sprayed concrete.

The removal of 9000 heavy vehicle movements of Sydney’s local and main roads.

Cost savings to the project by minimizing material consumption

Testing and Performance Criteria –

Key Steps in the Design Process

European standardEN 14487-1 mentionsthe different ways of specifying the ductility of fibrereinforced sprayed concretein terms of residual strengthand energy absorption capacity. It also mentions that both ways are not exactly comparable.

The energy absorption value measuredon a panel can be prescribed when – in case of rock bolting– emphasis is put on energy which has to be absorbed during the deformation of the rock. This is especially useful for primary sprayed concrete linings (EN 14488-5:Testing sprayed concrete, part 5: Determination of energy absorption capacity of fibre reinforced slab specimens). The residual strength can be prescribed when the concrete characteristics are used in a structural design model.

For primary sprayed concrete linings the residual strength will be the key material property to determined. For the characterization of a sprayed concrete, a procedure was proposed by EFNARC in accordance with prEN 14487-3, Method B. The procedure proposes a bending test on a 600 x 600 mm square panel and a thickness of 100 mm. This geometry is derived from the square panels typically adopted for temporary sprayed concrete in conventionally excavated tunnels, suggested by EN 14488-5.

The bending test is performed with a span of 500 mm (the same as adopted in EN 14651) and a notch with a depth of 10 mm, that is sawn at mid-span. The geometry and dimensions of the specimens, as well as the spraying method adopted, will ensure distribution of the fibers in the matrix, which is as close as possible to that encountered in the real structure. The dimensions of the test specimen will be acceptable for handling within a laboratory, as it involves no excessive weights or dimensions.

The test can be carried out, as far as the experimental means permit, in a normally equipped laboratory, as no exceptionally sophisticated equipment is necessary. The geometry will be the same as in the plate test for energy absorption (EN 14488-5). The plate can be sprayed on the job site, and there is no need to saw a prism from a panel, which could influence the result.

The scatter will be lower than the current standardized beam test. The notch will provide a slower cracking process, thereby reducing the risk of a sudden fail.

As with EN 14651, this test defines residual flexural strength (fR1, fR2, fR3, fR4) according to the updated international standard, fib Model Code 2010. The obtained mechanical property will serve as input for the dimensioning method.

By adopting the prEN 14487-3 method B testing procedure for the post-peak characterization of the sprayed fibre reinforced concrete, it is also possible to derive the parameters fct,L, fR1, fR3, that are necessary for the design according to Model Code 2010 and propose some minimum requirements as fR1k and fR3k.

ASQUAPRO (Association for the Quality of Shotcrete) is currently working on a testing program to validate a concrete mix design for permanent sprayed concrete, considering a performance class type C35/45 3c using 40 kg Dramix 4D.

Thanks to improvements in equipment, like spraying robots, and in the quality of control and design methods and calculation standards, it is more possible than ever before to see sprayed concrete as a permanent lining method

Thanks to improvements in equipment, like spraying robots, and in the quality of control and design methods and calculation standards, it is more possible than ever before to see sprayed concrete as a permanent lining method

Credit/Quelle: Bekaert

Conclusion

Recently, the use of steel fibre permanent sprayed concrete lining as a final lining has been gaining more and more attention in order to meet the structural and environmental developments.

Thanks to improvements in equipment like spraying robots and in the quality of control and design methods and calculation standards, it is more possible than ever before to see sprayed concrete as a permanent lining method. By rethinking tunnel designs, it is possible to reduce the thickness of concrete and of the excavated section, which in turn saves time and money. The space saved can also be kept available to facilitate later repair work. Reducing the thickness of concrete and substituting metal fiber reinforced concrete for reinforcement bars makes it possible to create structures which are more sustainable and reduces the carbon footprint.

An important challenge here is determining the mechanical properties of fibre reinforced sprayed concrete by using a three-point bending test on a test panel in accordance with prEN 14 488-3.

Fibre reinforced concrete acts on the tensile behavior of cracked concrete and imparts ductility to a fragile material. The excellent properties of fibre reinforced concrete, which overcome cracking, as well as its improved durability over reinforced concrete are why Bekaert continues to develop that material and also explain its economic success. The high performance 4D fibre developed for permanent spray concrete lining offers new possibilities for the designer. EPD certification (Environmental Product Declaration) provides environmental data certified by an independent body.

Steel still is the most recycled material, and the Bekaert R&D team, together with universities, continue to investigate recyclability. Remelted or reused steel could be directly reused as steel fibers to reinforce tunnels and mines. Steel fibre reinforced concret delivers a microplastic and pollution free solution, as is increasingly required by governments in sprayed concrete applications for subsea tunnels.

The life cycle assessment (LCA) is a set of standardized data. It quantifies a material‘s impacts on the environment over its entire existence, from extraction of the raw materials required for its production up to its end of life. This approach, combined with research into a low-carbon solution, will give new momentum to fibre reinforced concrete.

fib bulletin 83, October 2017

October 2020

Low-Carbon Lining Solutions

Bekaert offers a wide portfolio of fiber concrete reinforcement solutions, whether the project requires temporary/permanently sprayed concrete linings, cast-in-place or precast segmental linings. Dramix steel fibers are used in numerous tunnels and mines around the world and are a key component of a durable low-carbon lining.