Volvo L120 Electric Wheel Loader Goes Underground in Munich

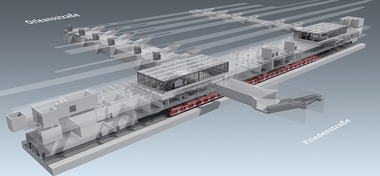

In the heart of Munich's city center, the ARGE Marienhof consortium, consisting of Implenia and Hochtief, is working on behalf of Deutsche Bahn on one of Germany's most ambitious infrastructure projects: the second S-Bahn main line. In one of the deepest excavation pits in the country, now 44 m below street level, a new underground station is being built at the Marienhof. This is also where the Volvo L120 Electric is being deployed as Europe's first fully electric large wheel loader in tough everyday tunnelling operations.

The L120 Electric is lowered through a narrow gap, 26 meters deep, via a crane

The L120 Electric is lowered through a narrow gap, 26 meters deep, via a crane

Credit/Quelle: Volvo Construction Equipment

All Electric

The conditions create pressure equivalent to a four-meter dive, posing challenges for both people and machines. With diesel-powered equipment considered too great a fire risk, only electric machines are being used. Volvo CE’s L120 Electric, Europe’s first fully electric wheel loader for everyday tunnelling, navigates these confined, environmentally sensitive spaces with ease, while also providing a much more pleasant place to work thanks to its zero exhaust fumes.

Reinhold Boiger, Implenia’s Senior Site Manager at Marienhof, explains: “Nobody is even allowed in the pressurized area without medical clearance. Only electrically powered equipment may be used under these conditions. Any diesel machine would be an incalculable risk.”

Customised Special Solution

This is where Volvo CE comes in. With the L120 Electric, the company has delivered Europe‘s first fully electric large wheel loader that can be used in compressed air conditions in tunnel construction – and this in the 20-ton class.

“The challenge was clear: a wheel loader that runs emission-free, requires no cables, and delivers enough power – deep underground and under pressure,” says Jascha Henjes, Key Account Manager at Volvo CE. “This is not a standard construction site. Special solutions were required here, and we delivered them with the L120 Electric.”

Volvo CE designed the customised solution in collaboration with ARGE Marienhof and dealer Robert Aebi and equipped it with particular safety features: The L120 Electric has rear and side cameras, person detection systems, and an automatic fire extinguishing system. For additional fire protection, a sensor system continuously monitors the battery temperature. “Safety is our top priority,” emphasizes Jascha Henjes. “This applies to our machines as well as to the people who work with them.”

The fact that the L120 Electric is now in use in the center of Munich is the result of an ambitious schedule. In November 2023, ARGE Marienhof set the requirements, and the machine had to be ready for use in January 2025. “It was a challenge,” recalls Jascha Henjes, “but we did it.” Paolo Mannesi, Sales Manager for Zero Emission Solutions at Volvo CE, adds: „Implementing projects like this naturally requires everyone in the entire value chain to pull together. And this is what we did here. Together with ARGE Marienhof, but also with our long-standing dealership partner Robert Aebi, we took on the challenge and mastered it. This project is a milestone for us.“

The switch to electric machines such as the L120 Electric also brings about a clear change for our dealership partner Robert Aebi. “We used to sell machines – today we deliver comprehensive solutions,” explains Claus Speldrich, Business Development Manager at Robert Aebi. This includes individual advice on charging infrastructure, deployment planning, special equipment, and comprehensive technical support. At the same time, service must also keep pace, in particular by training technicians in the new, highly complex battery technology.

Lowering the Wheel Loader by Crane

Reinhold Boiger, Implenia’s Senior Site Manager at Marienhof (left) with Jascha Henjes from Volvo CE

Reinhold Boiger, Implenia’s Senior Site Manager at Marienhof (left) with Jascha Henjes from Volvo CE

Credit/Quelle: Volvo Construction Equipment

Arrival of the wheel loader at the bottom of the Marienhof construction site

Arrival of the wheel loader at the bottom of the Marienhof construction site

Credit/Quelle: Volvo Construction Equipment

The wheel loader transports the excavated material from the working face to the transport skip

The wheel loader transports the excavated material from the working face to the transport skip

Credit/Quelle: Volvo Construction Equipment

Added to this is the logistical feat involved in delivering and operating a 20-ton machine in the middle of Munich‘s historic old town. Narrow access roads, listed buildings, pedestrian zones, delivery traffic, restaurants, and retail stores – all of this makes access to the construction site at Marienhof a precisely timed undertaking.

Every truck and every delivery is planned in advance down to the minute. “We assign fixed time slots. Anyone who arrives late has to wait or is turned away,” explains Reinhold Boiger. For the L120 Electric, this meant planning the transport through the city center on a low-loader with millimeter precision, followed by the spectacular lowering of the machine by crane to a depth of 26 meters.

Up to Eight Hours of Battery Operation

Matching the performance of its diesel counterpart, the L120 Electric is a 20-ton wheel loader offering up to eight hours of battery operation depending on the application, making it ideal for challenging underground operations like this. In Munich, the machine plays a central role throughout the day, efficiently transporting excavated material from the tunnel head to the skip for transport. Operating quietly and emission-free eliminates the need for air filtration.

Operators appreciate the machine’s electric drive, which enhances the work environment and control. They are also impressed with its modern ergonomics, intuitive operation, and all-round visibility thanks to integrated camera systems. For Boiger and this team, the L120 Electric wheel loader is just the beginning. “We want to use more machines like this, and not just in situations when we have compressed air,” he says. “Electric solutions are also the future of open tunnelling.”