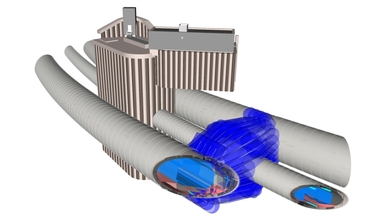

Marienhof in Munich: Construction of Germany’s Deepest S-Bahn Station Is Underway

In Munich‘s premium city centre location, an eye-catching structure visible from afar is attracting attention: two construction cranes with heights of up to 75 m, often colourfully illuminated at night, have been marking the construction site for Germany‘s deepest S-Bahn station since January 2021 (Fig. 1). As part of the urgently needed expansion of the S-Bahn network, a 41-metre-deep station is being built at Marienhof, which poses a great challenge technically, logistically and in terms of organisation. On the occasion of a site visit in May 2022, Jens Classen, Technical Project Manager of ARGE (JV) Marienhof, and his team presented the special aspects of this major project.

Around 6 million people live in the Munich region, 1.5 million of them in the city itself. With an increase in employment of around 23 % over the last ten years, the southern German metropolis is one of the fastest growing regions and commuter capital of Germany. Commuters extensively use the well-developed public transport network. One particularly busy section is the 11.3 km long 1st S-Bahn main line, which was opened in 1972 and runs through 4.3 km of the Munich city centre in tunnels.

It was originally designed for 250 000 passengers/day, but by now 850 000 people a day use the S-Bahn,...